Wafer transfer unit with blowdown function

A technology for conveying devices and wafers, applied in the directions of conveyor objects, transportation and packaging, cleaning methods and utensils, etc., can solve the problem that wafer conveying devices do not have a blowing function, etc., achieve good blowing effect and improve utilization rate , The effect of improving wafer yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention discloses a wafer transfer device with a blow-off function. The techniques such as the mechanism processing of each component are already understood by those with ordinary knowledge in the relevant technical field, so a complete description will not be given in the following description. Meanwhile, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be noted that the drawings are all in a very simplified form and use imprecise ratios, which are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

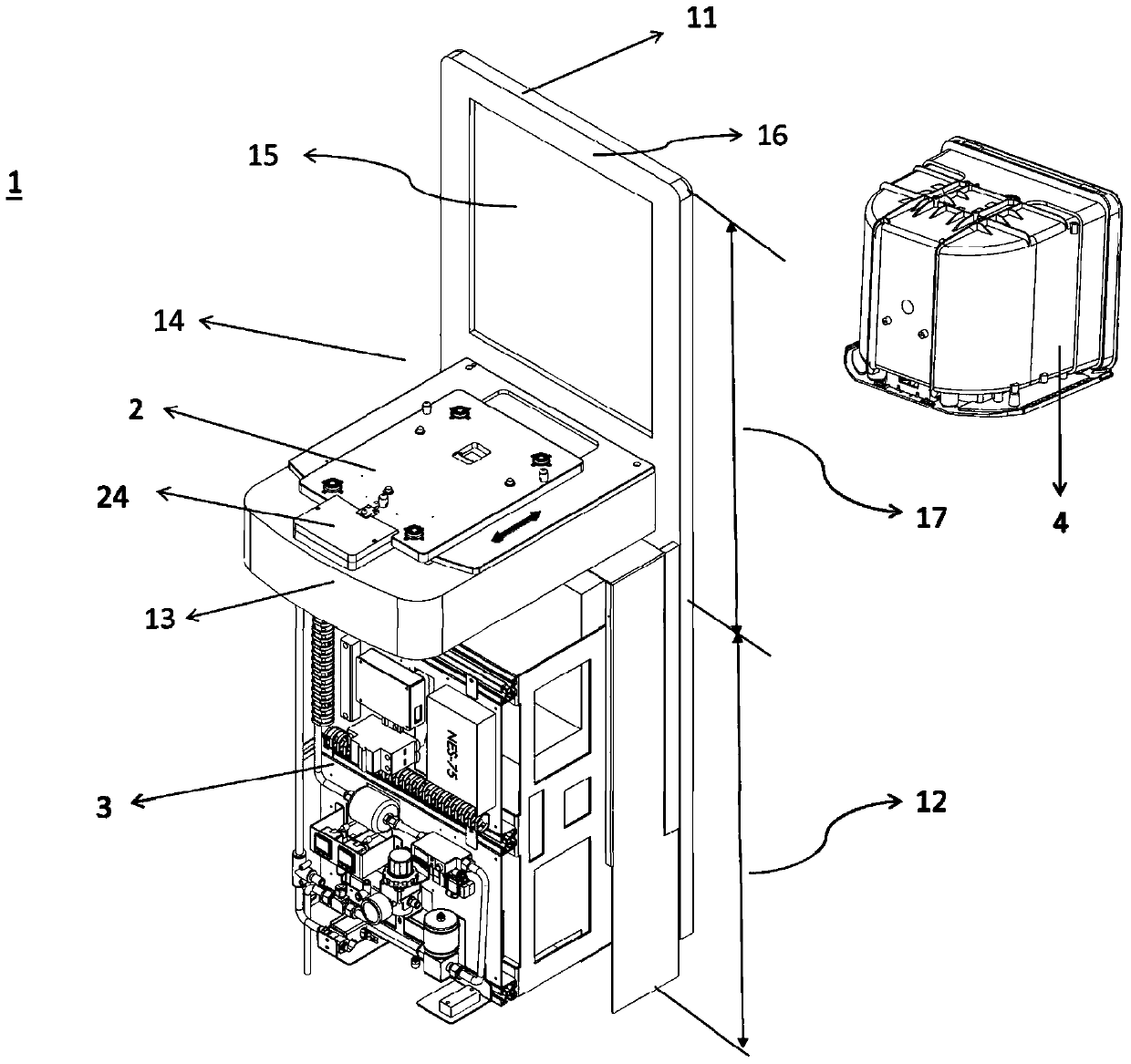

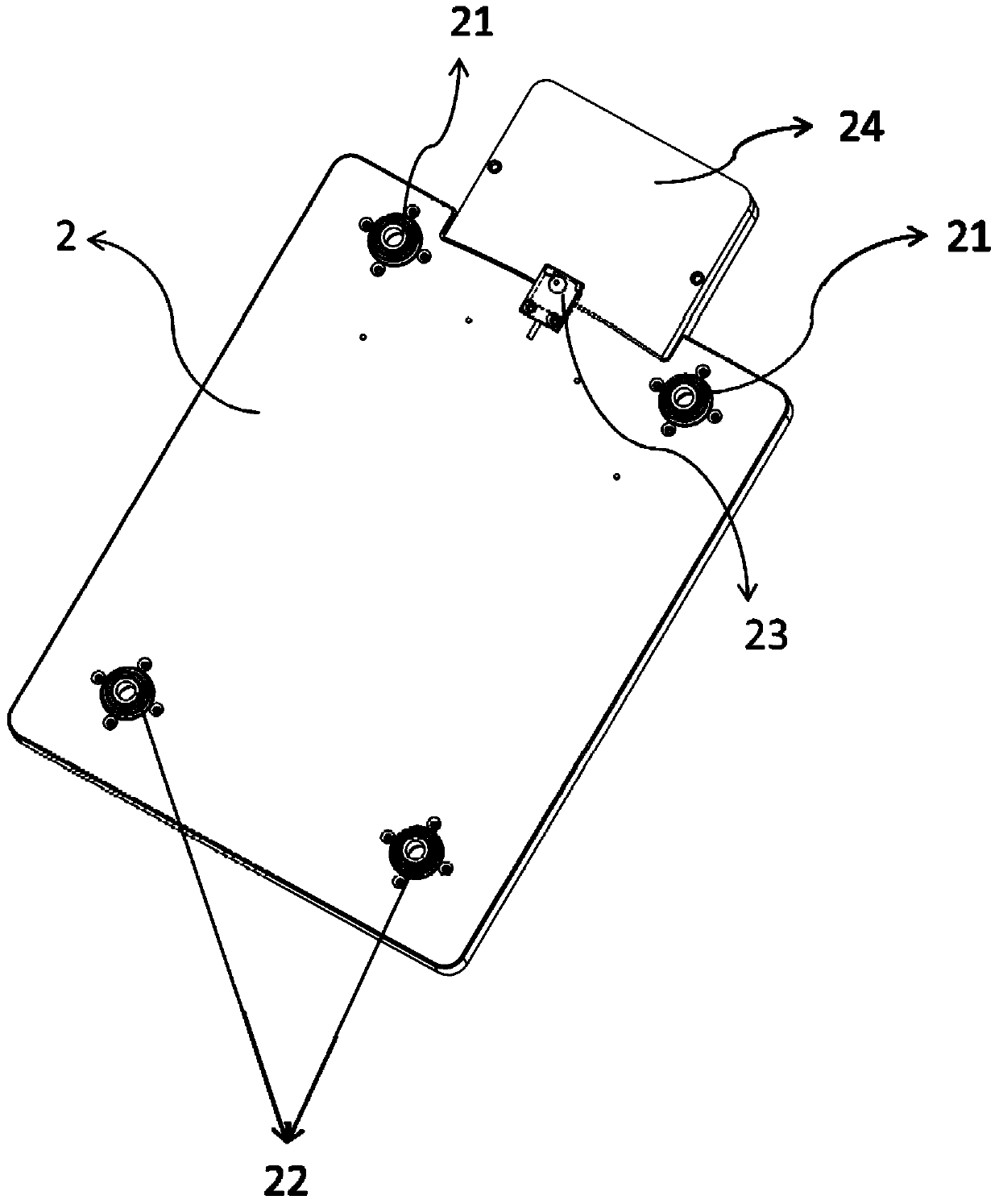

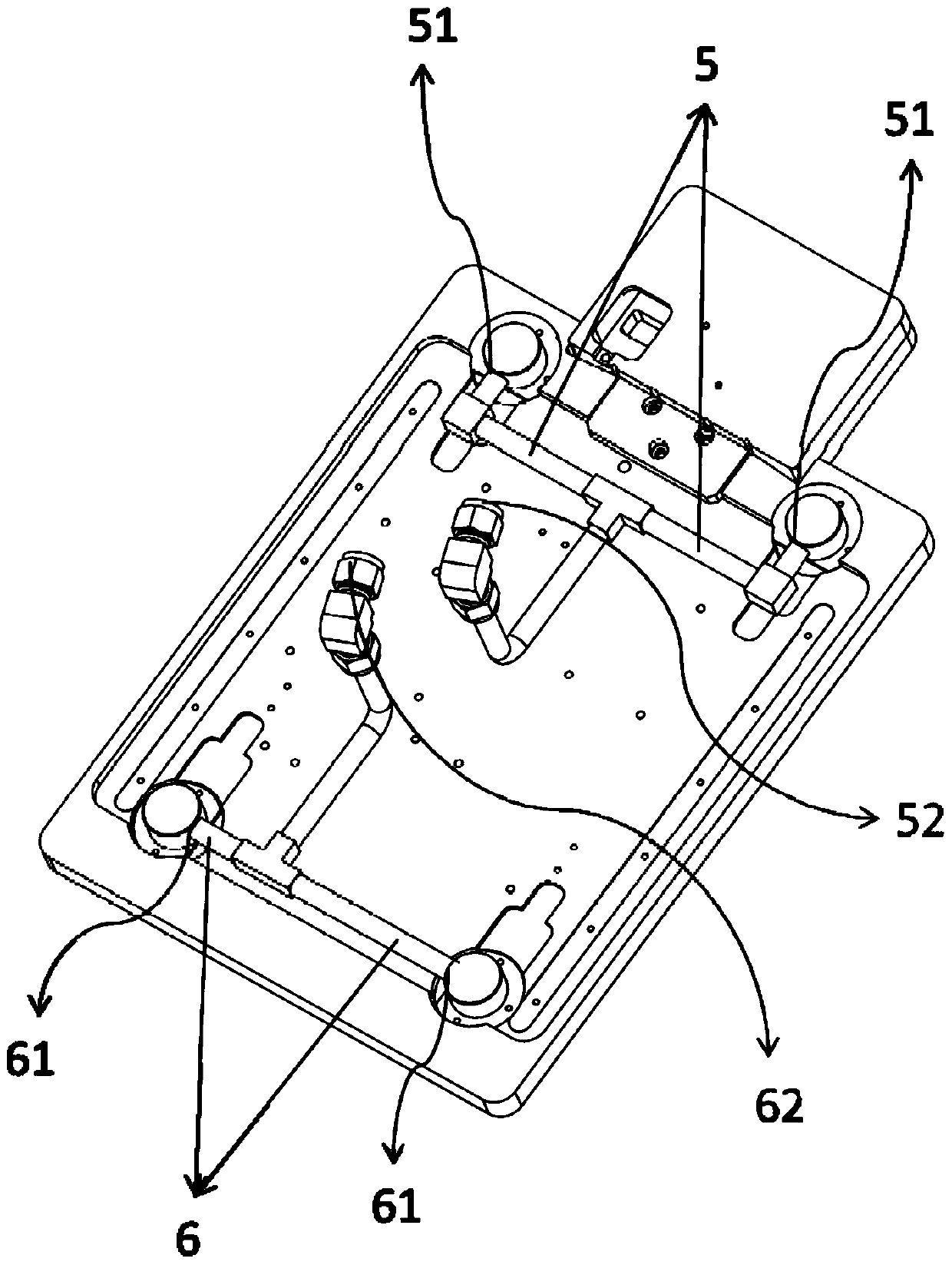

[0019] First, see figure 1 , is a schematic structural diagram of the wafer transfer device according to an embodiment of the present invention. Such as figure 1 As shown, there is a frame 11 erected vertically on the ground in the wafer transfer device 1, and the frame 11 is further divided into a lower half...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com