Trajectory planning method for double-robot coordinative assembling based on spline curve B

A dual-robot trajectory planning technology, applied in instruments, special data processing applications, electrical digital data processing, etc., can solve problems such as insufficient flexibility, easy assembly blind spots, and limited working space for a single robot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

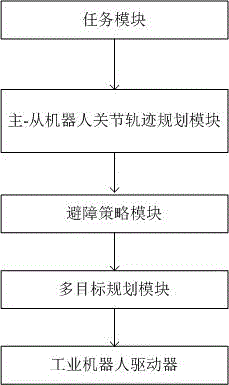

[0082] refer to figure 1 , the invention discloses a trajectory planning method for coordinated assembly of dual industrial robots based on B-spline curves, which includes a task module, a master-slave robot joint trajectory planning module, an obstacle avoidance strategy module, a multi-objective optimization module, and an industrial robot driver. The following is a description of the task of achieving a typical dual-industrial robot (six degrees of freedom) shaft-hole coordination assembly task as an example. Other tasks that meet the requirements can be implemented according to this plan, and the specific implementation steps are as follows:

[0083] Step 1. Establish the kinematics model of the dual industrial robot, and obtain the positive and negative solutions of the master-slave industrial robot;

[0084] The kinematics model means that each link coordinate system of the master-slave robot can be established respectively by the D-H method, the kinematics forward so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com