Analysis method for blade root stress based on neural network algorithm

A neural network algorithm and stress analysis technology, applied in the field of steam turbine blades, can solve the problems of slow three-dimensional nonlinear large deformation, etc., and achieve the effect of solving slow calculation speed and solving a large amount of pre-processing work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

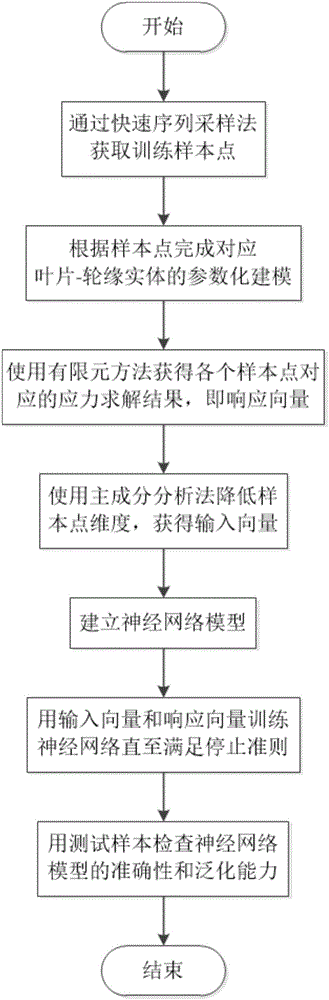

[0039] see figure 1 Shown, a kind of blade root stress analysis method based on neural network algorithm of the present invention comprises following five steps:

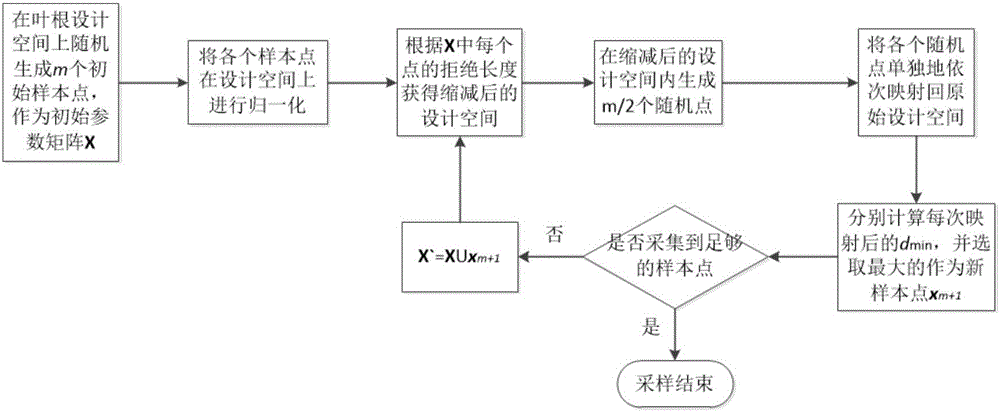

[0040] 1. Obtain the leaf-root model sample point set learned by the neural network by using the space-reduced fast uniform sequence sampling method.

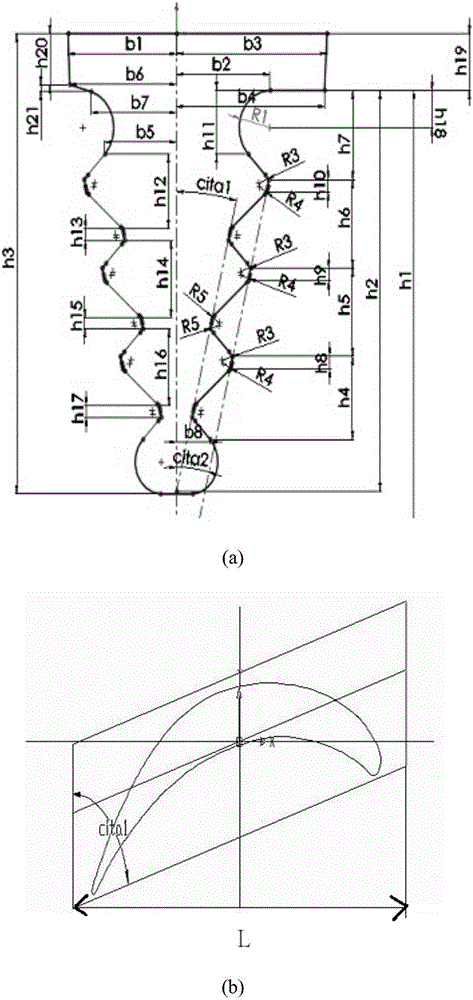

[0041]For a leaf root that needs n parameters to determine the geometric shape, it is known that there are m training sample points in its design space (each sample point contains a set of parameters that can determine the geometric size of the leaf root, such as carrying surface width, blade root axial length, etc.). After normalizing the n parameters on its design space, the initial parameter matrix X of the leaf root sample can be obtained = {x 1 ,x 2 ,...,x m} T ,in for a sample point. In order to improve the calculation accuracy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com