Touch substrate, preparation method thereof and touch screen

A substrate and touch technology, applied in optics, instruments, electrical digital data processing, etc., can solve the problems of difficulty in meeting the requirements of the overall light transmittance of the functional hole area and the reduction of the overall light transmittance of the functional hole area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

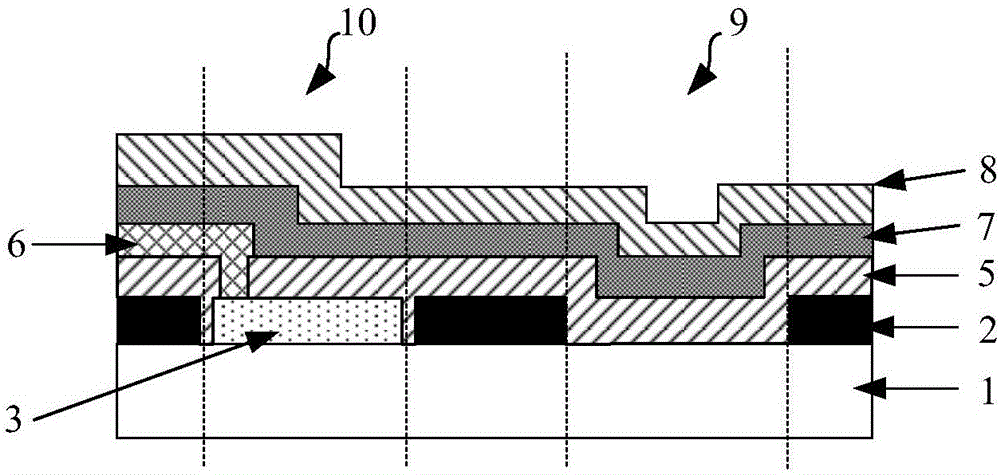

[0063] Figure 4 It is a schematic structural diagram of the touch substrate provided in Embodiment 1 of the present invention, Figure 5 The top view of the functional hole area in the touch substrate provided by the present invention, such as Figure 4 with Figure 5 As shown, the touch control substrate includes: a base substrate 1 on which a light-shielding pattern 2 is formed, and the light-shielding pattern 2 defines a touch area 10 and a functional hole area 9 . It should be noted that the situation of a touch area 10 and a function hole area 9 shown in the drawings is only for illustrative purposes, which will not limit the technical solution of the present invention, and those skilled in the art should know Yes, the shape, quantity, size, and position of the touch area 10 and the functional hole area 9 can be adjusted accordingly according to actual needs, and specific examples will not be illustrated here.

[0064] In the touch area 10 , a touch unit located above...

Embodiment 2

[0077] Image 6 A schematic structural diagram of the touch substrate provided in Embodiment 2 of the present invention, as shown in Image 6 as shown, Image 6 The touch substrate shown with the Figure 4 The difference of the touch substrate shown is that, the second insulating layer pattern 8 is arranged above the first disappearing pattern 71, and the anti-reflection pattern 4 is located above the second disappearing pattern 72 and is arranged on the same layer as the second insulating layer pattern 8. .

[0078] It should be noted that the material of the second insulating layer pattern 8 is generally an organic material, so when forming the second insulating layer pattern 8 and the anti-reflection pattern 4, it is only necessary to use a mask (Mask) to expose and develop the organic material to complete the composition. In addition, the film thickness (odd multiples of 1 / 4 light wave wavelength) of the material layer used to form the second insulating layer pattern 8...

Embodiment 3

[0081] Figure 7 It is a flow chart of a method for manufacturing a touch substrate provided in Embodiment 3 of the present invention, Figure 8 for adoption Figure 7 Schematic diagram of the intermediate structure of the touch substrate prepared by the preparation method shown, as shown in Figure 7 with Figure 8As shown, the preparation method is used to prepare the touch substrate in the first embodiment above, and the preparation method includes:

[0082] Step S101 , forming a light-shielding pattern above the base substrate, where the light-shielding pattern defines a touch area and a functional hole area.

[0083] In step S101 , first deposit a layer of light-shielding material film on the base substrate 1 , and then pattern the light-shielding layer material to obtain a light-shielding pattern 2 , which defines the touch area 10 and the functional hole area 9 . Only one touch area 10 and one function hole area 9 are shown in the figure as an example.

[0084] Ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com