Fiber screening machine rapid brake apparatus and method

A screening machine and fast technology, applied in the direction of program control, electrical program control, general control system, etc., can solve problems such as poor economy, no energy saving, damage, etc., to reduce equipment energy consumption, reduce loss, and reduce installed capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

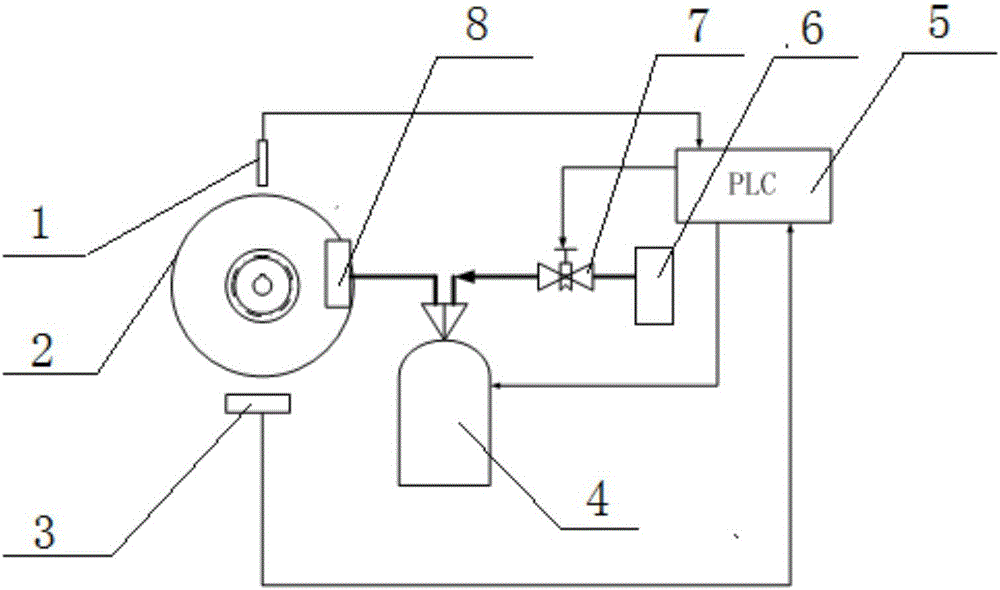

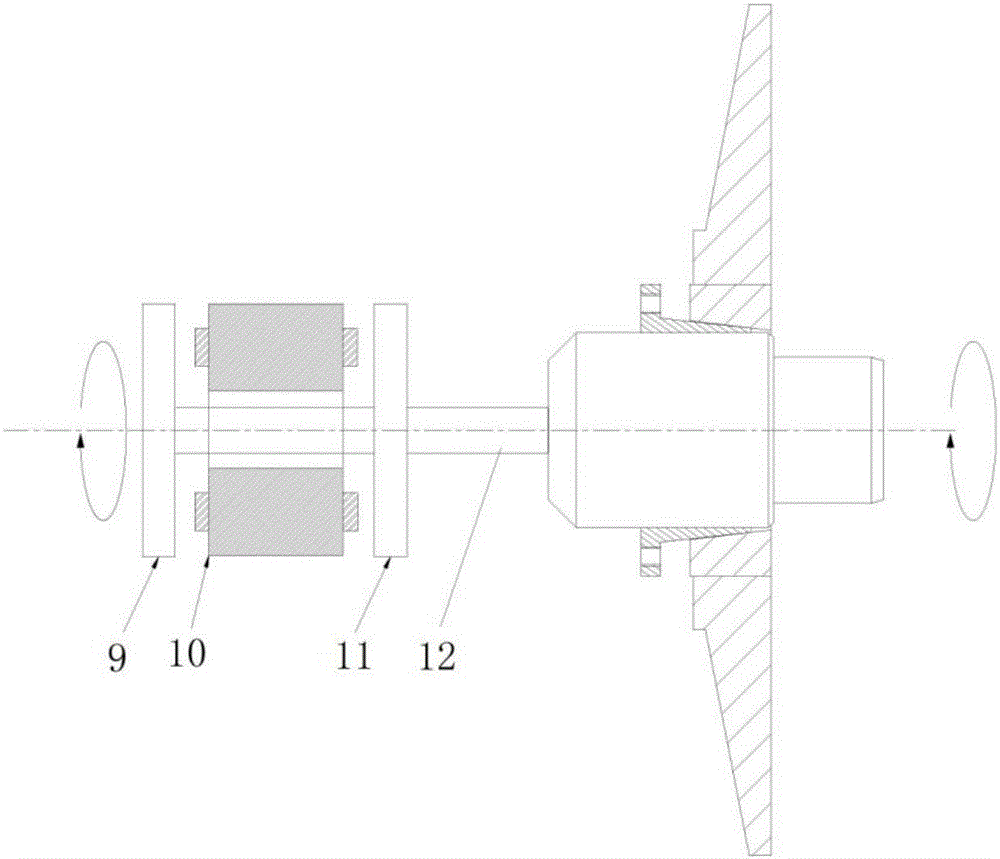

[0026] Such as figure 2 As shown, this embodiment provides a fast braking device for an optical fiber screening machine, including a pneumatic brake 8, a pressure controller 4, a solenoid valve 7, a compressed air source 6, a PLC controller 5, a speed detection device 1, and an inertia detection device. Device 3. The pneumatic brake is configured with the pay-off main shaft of the pay-off barrel end 2, the air inlet of the pressure controller 4 is connected with the air outlet of the electromagnetic valve 7, and the air outlet is connected with the air inlet of the pneumatic expansion disc 10, Described electromagnetic valve 7 is arranged on the pipeline of the outlet of compressed air source; Described speed detecting device 1 is used for detecting the speed of the main shaft of paying off line, and it can be speed sensor, and it is arranged on the driving motor of main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com