Matrix LED headlamp test system and matrix LED headlamp test method

A test method and technology for headlights, which are applied in diode testing, single semiconductor device testing, etc., to achieve good functions and performance, improve efficiency and accuracy, and improve safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

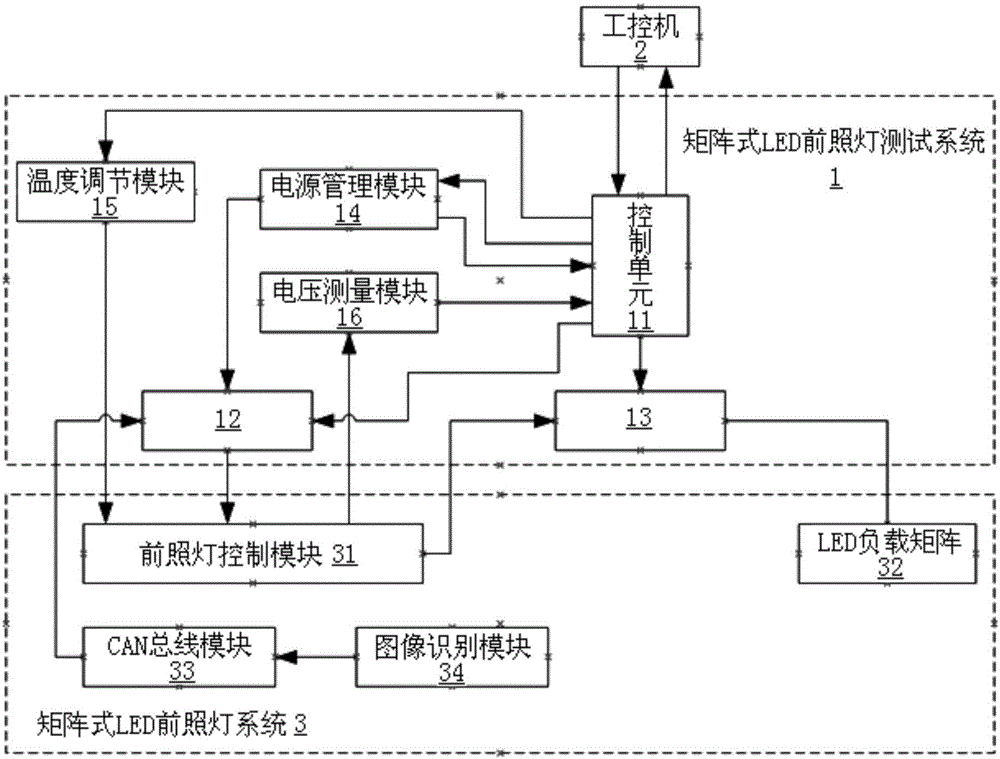

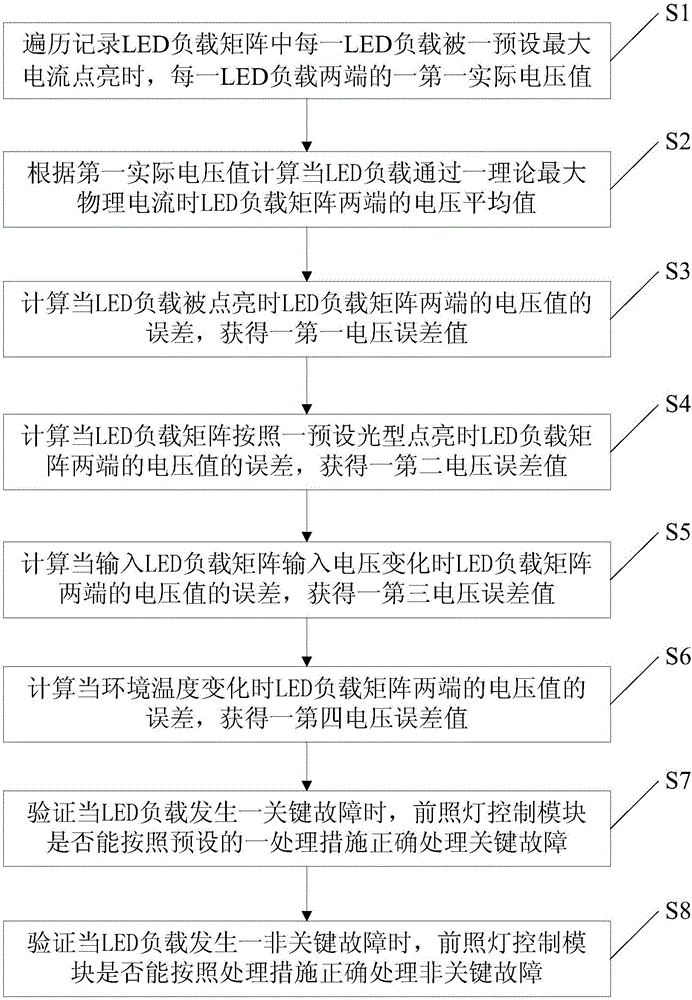

[0072] According to the attached figure 1 , 2 , give a preferred embodiment of the present invention, and give a detailed description, so that the functions and characteristics of the present invention can be better understood.

[0073] see figure 1 , a kind of matrix type LED headlamp test system 1 that the present invention implements, comprises: a control unit 11, a first fault input module 12, a second fault input module 13, a power management module 14, a temperature regulation module 15 and a voltage measurement module 16.

[0074] Wherein, the control unit 11 communicates with an external industrial computer 2, and is used to control the operation of each module in the matrix LED headlamp test system 1, collect data and perform data interaction with the industrial computer 2.

[0075] The first fault input module 12 is connected to the control unit 11 and a matrix LED headlight system 3, and is used to add an external wiring harness fault to the matrix LED headlight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com