Negative clearance rotation measurement method for third-generation hub bearing unit

A rotary measurement and wheel bearing technology, applied in the field of bearings, can solve the problem of difficulty in directly measuring the negative clearance value of the third-generation wheel hub bearing unit, and achieve the effect of fast measurement speed, product quality assurance, and accurate measurement results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

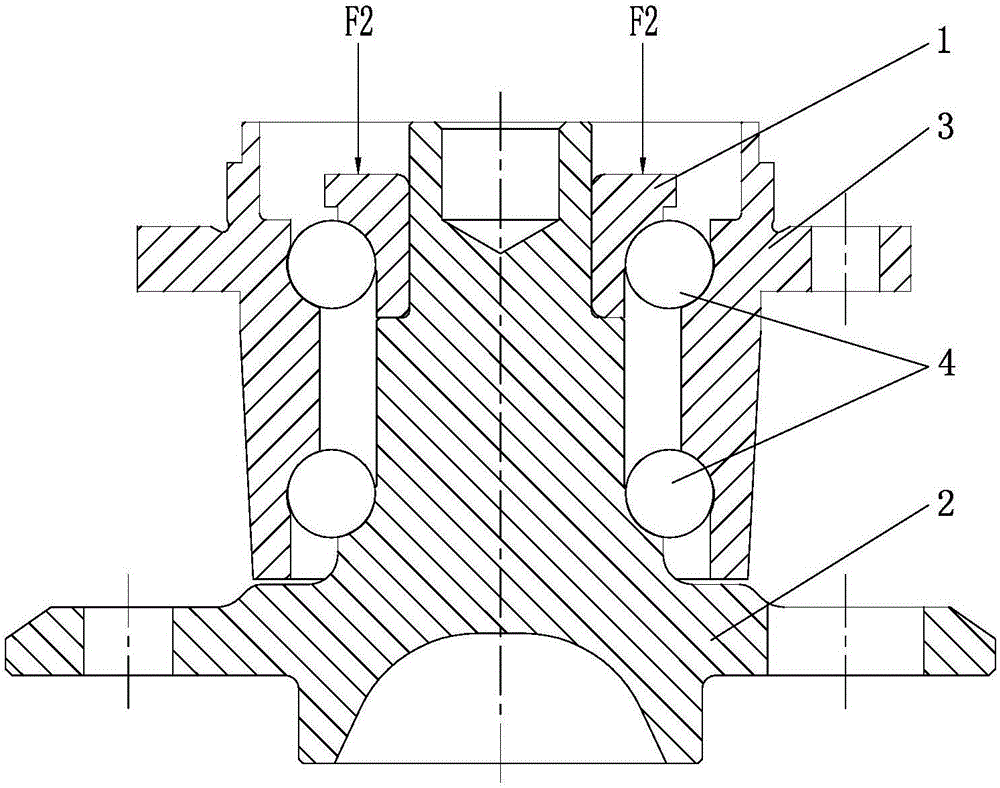

[0018] Such as figure 1 , figure 2 As shown, after the components of the above-mentioned third-generation hub bearing unit are prepared, the negative clearance measurement method includes the following steps:

[0019] 1) First assemble the first inner ring 1, the second inner ring 2, the outer ring 3, the steel ball 4 and the cage together.

[0020] 2) Next, put the small end of the first inner ring 1 downward on the shaft at the upper end of the second inner ring 2, press the second inner ring 2 to fix it, and apply a downward force on the large end of the first inner ring 1. The pressure F1 is preloaded so that the small end surface of the first inner ring 1 and the shoulder of the second inner ring 2 maintain a distance a, and the value of a is 0.1-0.15mm.

[0021] 3) Control the first inner ring 1 and the second inner ring 2 to rotate synchronously, and the speed is not more than 150 rpm, and apply force sequentially on the upper and lower ends of the outer ring 3 flang...

Embodiment 2

[0026] Such as figure 1 , figure 2 As shown, after the components of the above-mentioned third-generation hub bearing unit are prepared, the negative clearance measurement method includes the following steps:

[0027] 1) First assemble the first inner ring 1, the second inner ring 2, the outer ring 3, the steel ball 4 and the cage together.

[0028] 2) Next, put the small end of the first inner ring 1 downward on the shaft at the upper end of the second inner ring 2, press the second inner ring 2 to fix it, and apply a downward force on the large end of the first inner ring 1. The pressure F1 is preloaded so that the small end surface of the first inner ring 1 and the shoulder of the second inner ring 2 maintain a distance a, and the value of a is 0.1-0.15mm.

[0029] 3) Control the first inner ring 1 and the second inner ring 2 to rotate synchronously, and the speed is not more than 150 rpm, and apply force sequentially on the upper and lower ends of the outer ring 3 flang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com