Flange with hole and safety valve pressure test system based on flange with hole

A pressure test and safety valve technology, applied in the field of safety valves, can solve problems such as pipeline leakage, economic losses of factories and enterprises, personal injury, etc., and achieve the effects of increasing service life, accurate testing data, and convenient disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

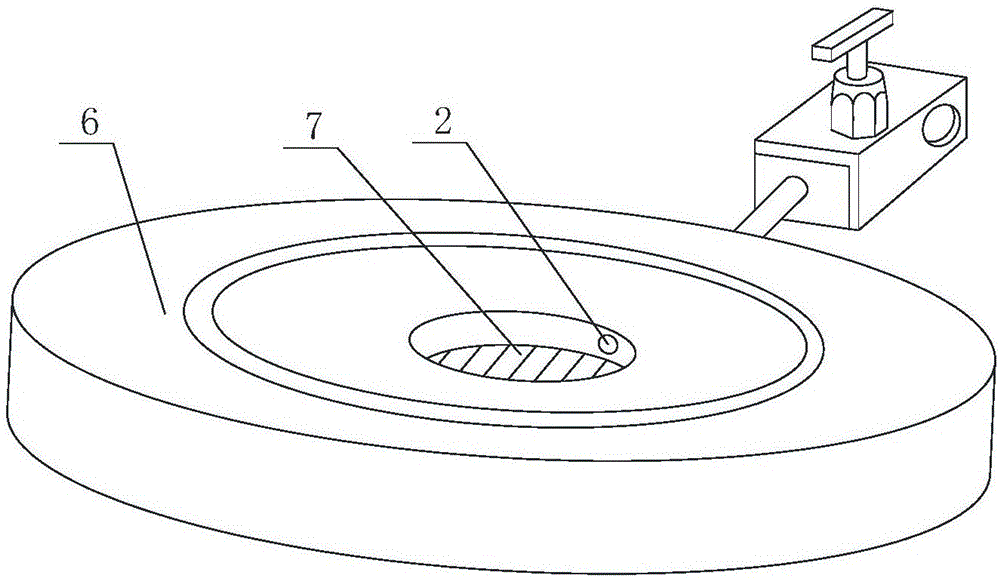

[0033] Such as figure 1 As shown, a perforated flange of the present invention includes a flange 1, a hole 3 concentric and coaxial with the flange 1 is provided at the center axis of the flange 1, and a circumscribed flange 1 is provided on the side wall of the flange 1. Hole 2, the external connection hole 2 communicates with the channel 3.

[0034] The flange with external connection holes of the present invention is used for safety valve detection and verification in the fields of petroleum and natural gas industry, chemical industry, power plant, etc.; The pressure value in the pipeline system where the valve is located reaches the set pressure value of the safety valve, and whether the safety valve is qualified is judged by judging whether the safety valve is opened under the set pressure; The intermediate equipment of the pipeline system, the pressurized equipment is connected with the external hole of the flange, and the additional gas is passed into the hole of the f...

Embodiment 2

[0036] Such as figure 1 , figure 2 As shown, based on Embodiment 1, the flange 1 is a straight-through flange 4, and the through-hole 5 is opened on the straight-through flange 4, and the through hole 5 is equivalent to the tunnel 3.

[0037] The flange in the present invention adopts a straight-through flange, which is suitable for the safety valve pressure test system, where the safety valve is provided with a safety valve root valve, and the safety valve root has good air tightness. , directly install the straight-through flange between the safety valve and the root valve of the safety valve, and then connect the pressurizing equipment to the straight-through flange and communicate with the external connection hole to perform pressure testing on the safety valve; The invention uses the straight-through flange to detect the safety valve without stopping production. After the safety valve is tested, the safety valve can be disassembled or not. The straight-through flange is...

Embodiment 3

[0039] Such as figure 1 , image 3 As shown, based on Embodiment 1, the flange 1 is a blind plate 6, and a blind hole 7 is opened at the center of the blind plate 6, and the bottom of the blind hole 7 is closed, and the blind hole 7 is equivalent to the channel 3.

[0040] The present invention adopts a blind plate with an external connection hole as the intermediate connecting device between the pressurizing equipment and the safety valve pressure test system, and is suitable for the situation where the safety valve root valve is not installed at the lower end of the safety valve. In the safety valve pressure test system, there is no safety valve installed. The valve root valve has poor airtightness; the blind hole of the blind plate is the circulation channel of the pressurized gas, and the bottom of the blind hole is closed and has good airtightness, so the pressurized gas directly passes through the blind hole The safety valve can be used to detect the safety valve; the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com