Box-type portable edge protection fence for construction site safety management

A safety management and construction site technology, applied in the processing of building materials, construction, building structure, etc., can solve the problems of production standardization, standardization, batch production, waste of resources, time-consuming and labor-intensive, etc., and achieve individual handling and movement Easy and fast, convenient installation and disassembly, and the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

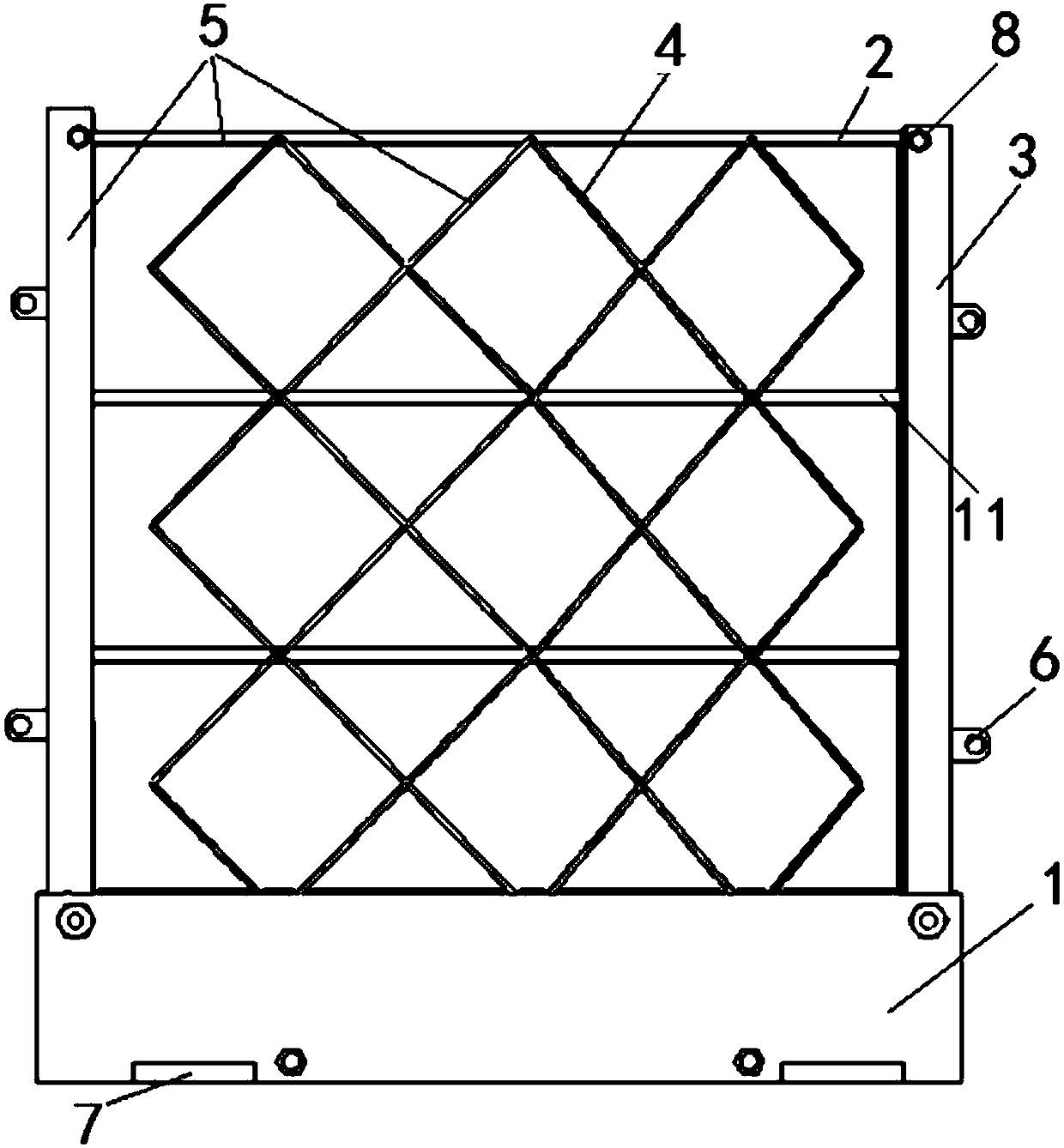

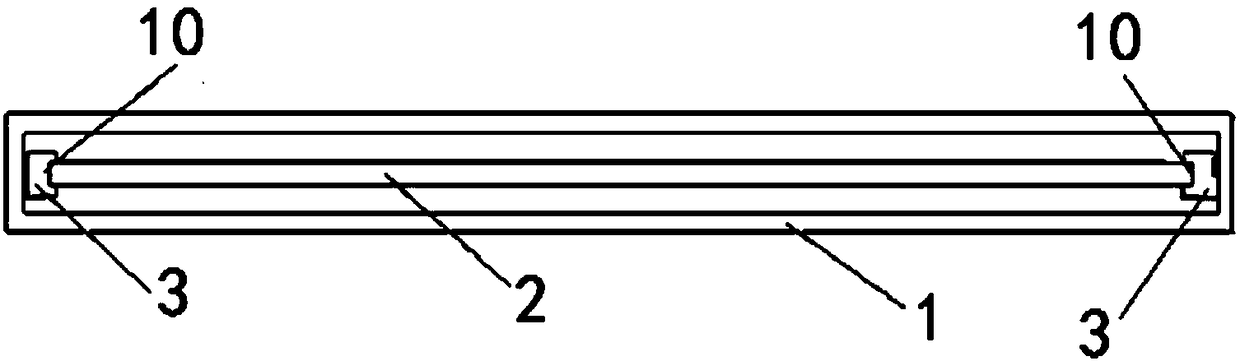

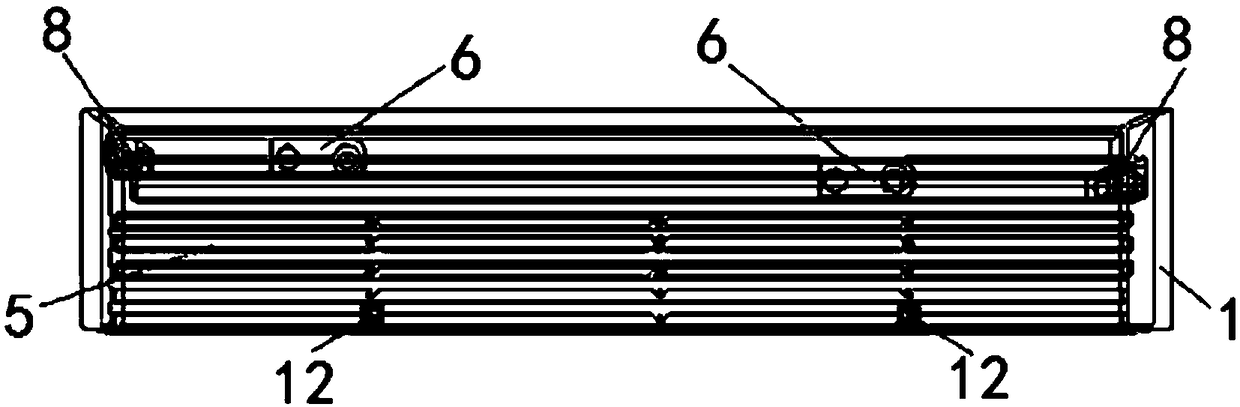

[0039] An embodiment of the box-type portable border guardrail used for safety management on construction sites of the present invention, such as figure 1 , figure 2 and image 3 As shown, it consists of at least one edge guardrail unit; such as Figure 4 and Figure 5 As shown, if multiple border guardrail units are to be connected, then a plurality of border guardrail units are connected sequentially through columns 14; each border guardrail unit is composed of a box body 1 and a telescopic net assembly 5 connected to the box body 1, And the box body 1 is in the shape of a cube; the telescopic mesh assembly 5 can be deployed in an upward manner, and can also be contracted in a downward manner and be stored in the box body 1 .

[0040] Telescopic guard net assembly 5, such as figure 1 , figure 2 and image 3 As shown, it includes tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com