Material milling device

A stone grinding and rolling technology, applied in the field of rolling equipment, can solve the problems of easy falling from the grinding plate and laborious and laborious transfer process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

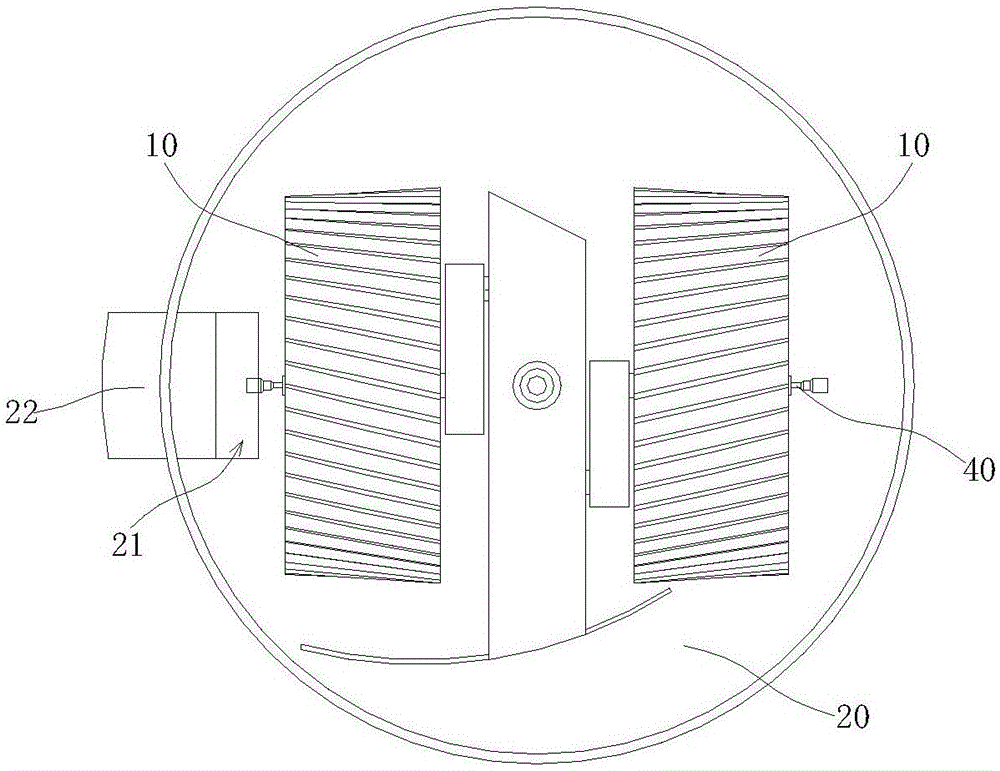

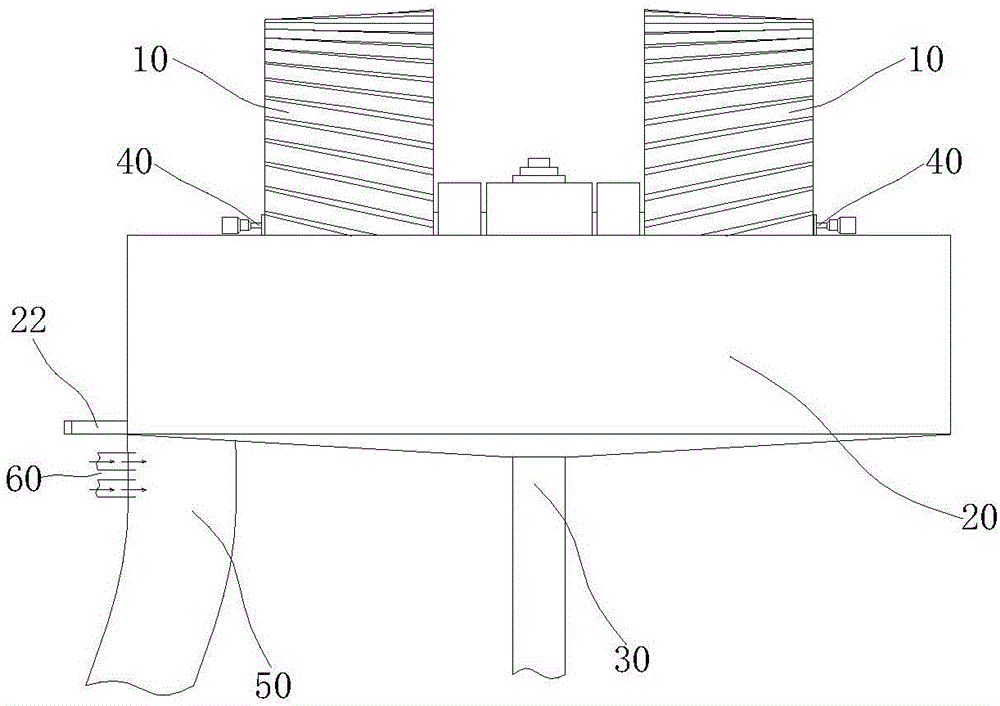

[0008] combine figure 1 and figure 2 The present invention is described further:

[0009] A grinding device, comprising a stone mill 10, the mouth of the cylinder 20 is upward, the vertical main shaft 30 is connected to the stone mill 10 via a flat stone mill shaft 40, the roller surface of the stone mill 10 is connected to the cylinder The inner cylinder bottom of 20 forms a rolling fit. The inner cylinder bottom of the roller 20 is provided with a discharge port 21, and the gate plate 22 is correspondingly arranged at the discharge port 21, and the bottom of the discharge port 21 is correspondingly extended. A feeding pipe 50 is arranged to communicate with the straw pulp pool, and a water injection pipe 60 is arranged below the discharge port 21 to extend to the inside of the feeding pipe 50 . The main rotating shaft 30 is connected with the driving mechanism to drive the stone mill shaft 40 to rotate circumferentially. The stone mill 10 revolves around the main rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com