Negative pressure foaming method for preparing epoxy resin foam with air as blowing agent

A technology of epoxy resin and foaming agent, applied in the field of negative pressure foaming, to avoid environmental pollution problems and health threats, simple formula and good versatility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Weigh 100g of E44 type bisphenol A type epoxy resin and preheat to 35°C. Weigh 20g of curing agent T31 and 20g of curing agent NX2040 at a mass ratio of 100:40, and pour them into the preheated epoxy resin together. Put the prepared initial material in the mixer, and ensure that the length of the mixer blade is slightly smaller than the diameter of the cup mouth (there is a space of about 0.5cm on both sides). Adjust the stirring environment temperature of the mixer to 40±3°C, set the stirring speed at 1200±120rpm, and control the stirring time at 15±1.5min. After setting the stirring parameters, start high-speed stirring. After stirring, measure the initial material with a rotary viscometer The viscosity value is 5020mPa·s. Take out the mixed material that has been stirred, pour it into an open mold preheated to 60°C, and then put the mold into a vacuum oven with a constant temperature of 60°C. Open the air valve of the oven, connect the vacuum pump for vacuuming, an...

Embodiment 2

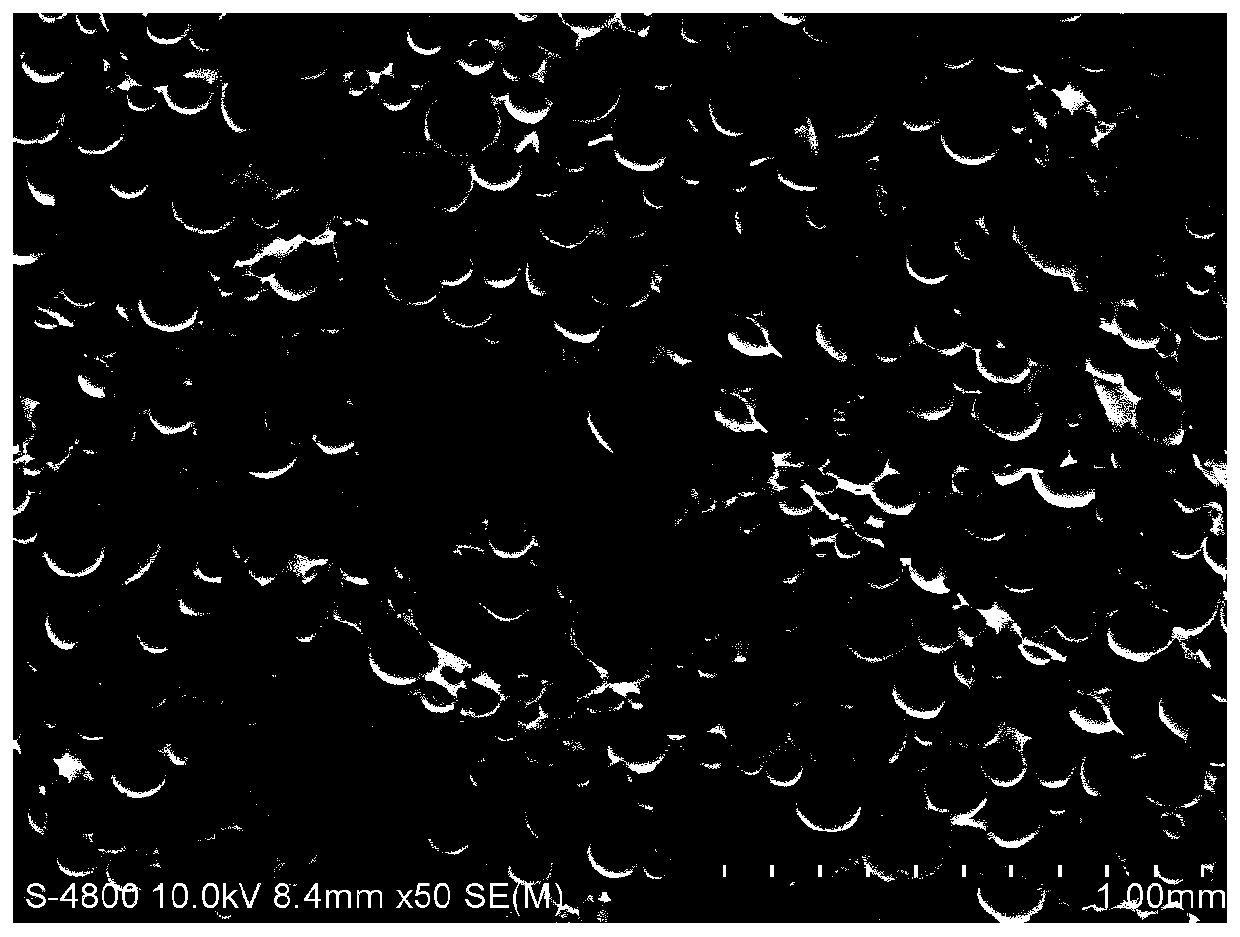

[0020] Other steps and conditions of this embodiment are the same as those of Example 1, except that the foaming mold preheating temperature and foaming temperature are both set to 80° C., and the foaming air pressure is set to 0.04 MPa to prepare a foam material with a low foaming rate. After testing, the density of the epoxy resin foam material prepared in this embodiment is 0.38g / cm 3 (Foam rate 2.30). SEM results such as figure 2 shown, from figure 2 It can be seen in (50 times magnification) that the epoxy resin foam material has uniform and closed cells.

Embodiment 3

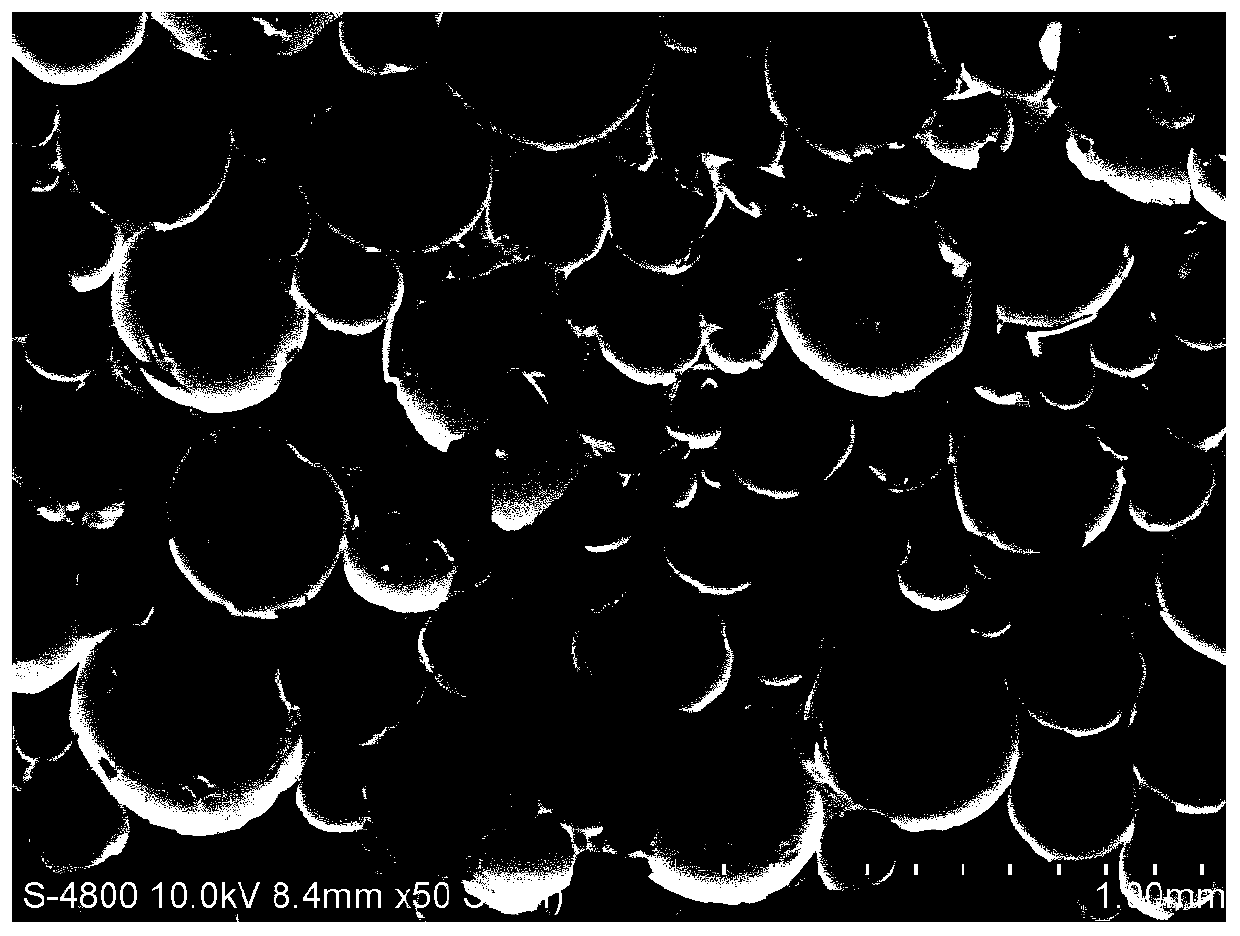

[0022] The other steps and conditions of this embodiment are the same as those of Embodiment 1, except that the preheating temperature of the foaming mold and the foaming temperature are both set to 120° C., and the foaming pressure is set to 0.01 MPa to destroy the internal pores and form through holes. After testing, the density of the epoxy resin foam material prepared in this embodiment is 0.151g / cm 3 (Foam rate 6.28). SEM results such as image 3 Shown (50x magnification), from image 3 It can be seen that the epoxy resin foam material has uniform cells and a through-hole structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com