Petroleum pipe lifting device for ship

A lifting device, oil pipe technology, used in transportation and packaging, load hanging components, cranes, etc., can solve the problems of large space occupation and large volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

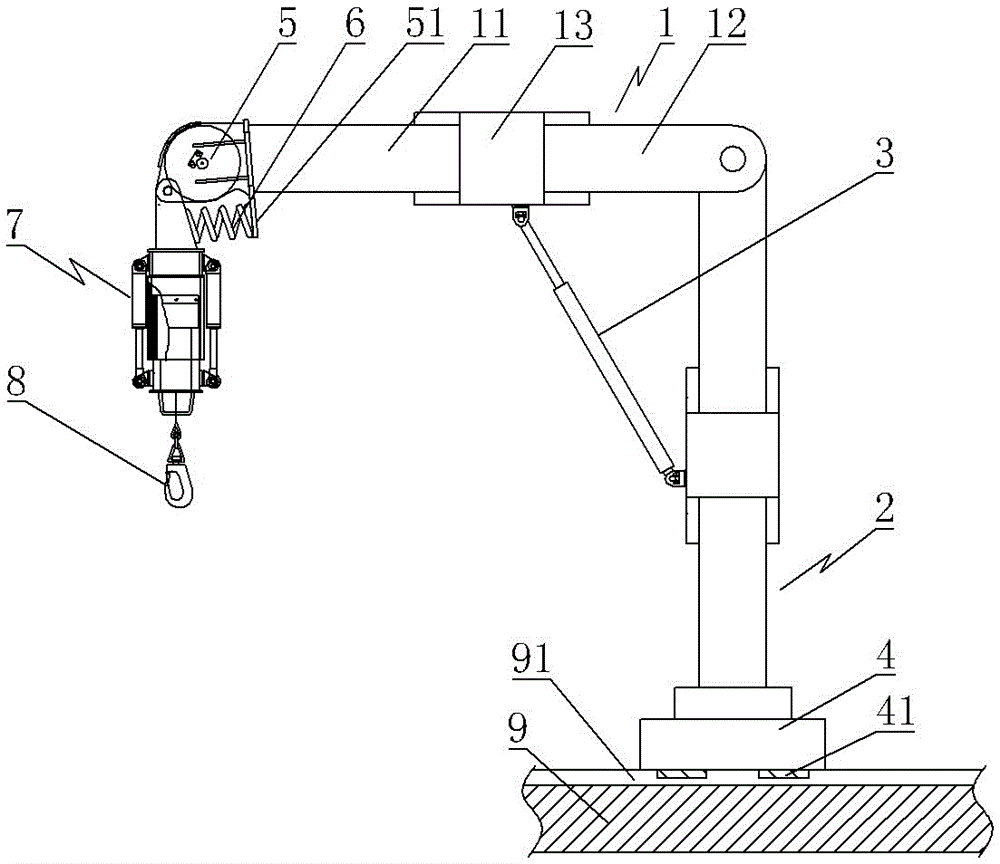

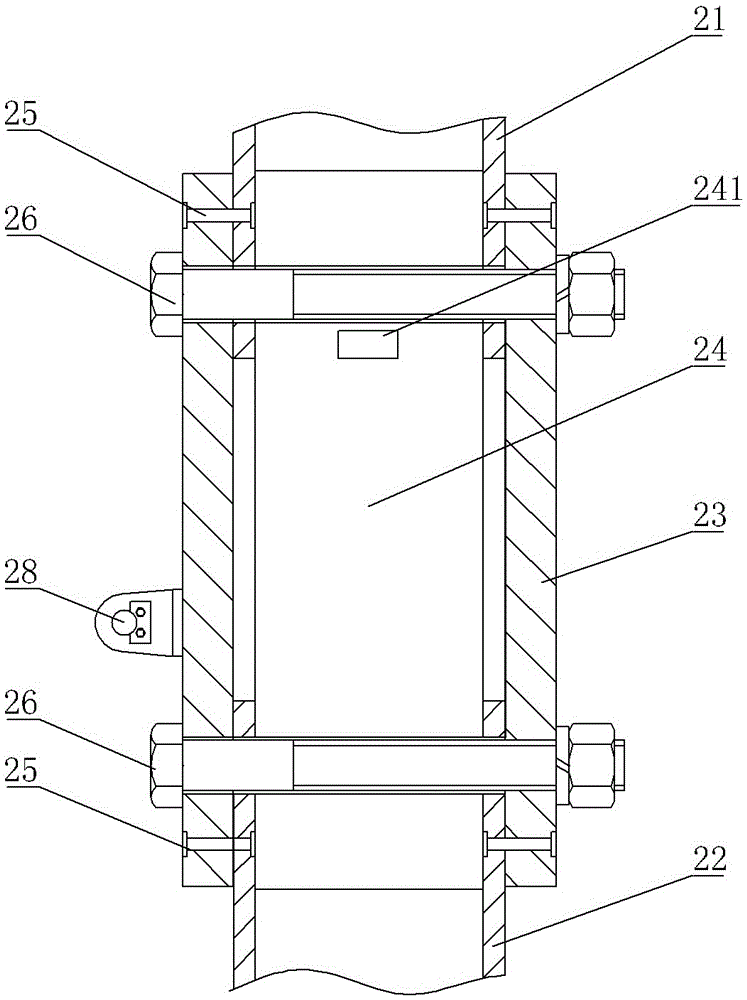

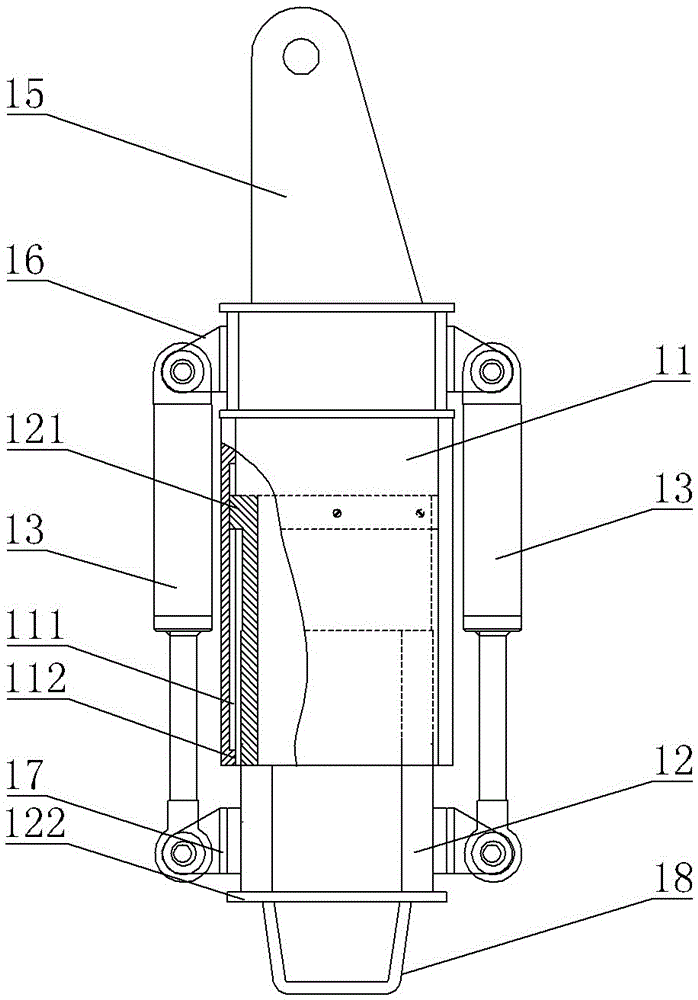

[0014] Such as Figure 1~Figure 3 As shown, the oil pipe lifting device for ships includes a transverse boom 1, a longitudinal boom 2, a winch, a wire rope (not shown in the figure) and a hook 8, and the transverse boom 1 is supported in the longitudinal direction by the boom hydraulic rod 3. The boom 2 is hinged with the longitudinal boom. The end of the transverse boom is provided with a roller bracket 5. One end of the wire rope is connected to the hook, and the other end passes through the roller bracket to connect to the winch. Both the transverse boom and the longitudinal boom include several booms. Single body, connecting sleeve, connecting rod and fixed components, taking the longitudinal boom as an example, such as figure 2 As shown, the boom monomers 21 and 22 are rectangular tube structures, the outer sides of the opposite connecting ends of the adjacent boom monomers 21 and 22 are connected by the sleeved connecting sleeve 23, and the inner side is connected by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com