3d printing nozzle and intelligent control 3d printing nozzle

A 3D printing and nozzle technology, which is used in manufacturing auxiliary devices, processing data acquisition/processing, additive processing, etc., can solve the problems of low equipment utility and single material selection, so as to improve utility, improve equipment, and solve the problem of fixed printing environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

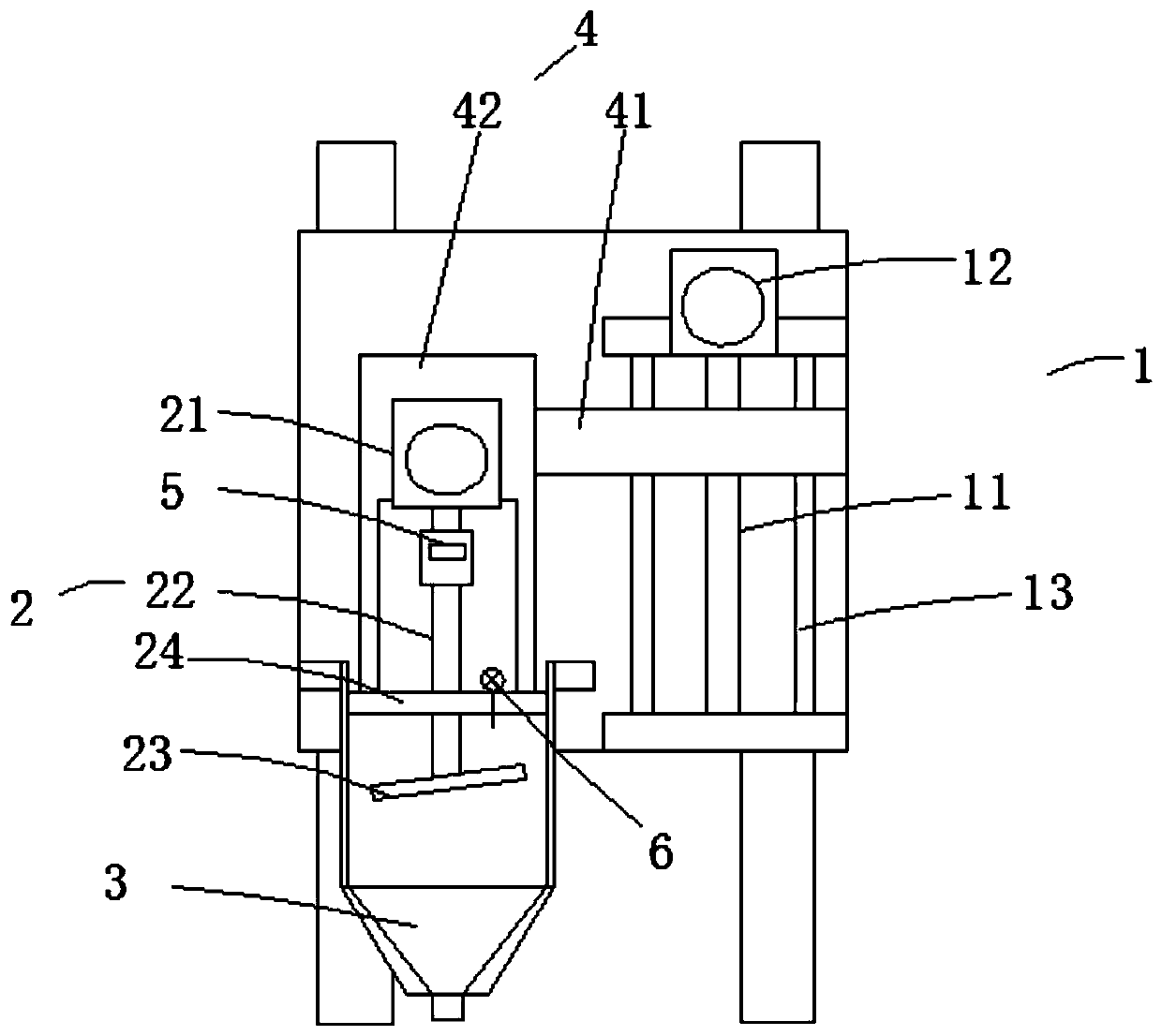

[0046] Please refer to figure 1 ; The 3D printing nozzle provided by the present invention includes: a driving device 1, a storage control device 2, a storage device 3 and a processor;

[0047] The driving device 1 is connected to the material storage control device 2 through the connecting piece 4; the driving device 1 drives the material storage control device 2 through the connecting piece 4 to compress and rotate the material up and down in the material storage device 3;

[0048]The processor is used to collect the temperature and pressure values in the material storage device 3 in real time, and to collect the torque value of the material being stirred by the material storage control device 2 in real time, so as to output control signals to the drive device 1, the material storage control device 2 and the material storage device 3 They are respectively controlled, and then the corresponding stirring speed, temperature and pressure values in the material storage device...

Embodiment 2

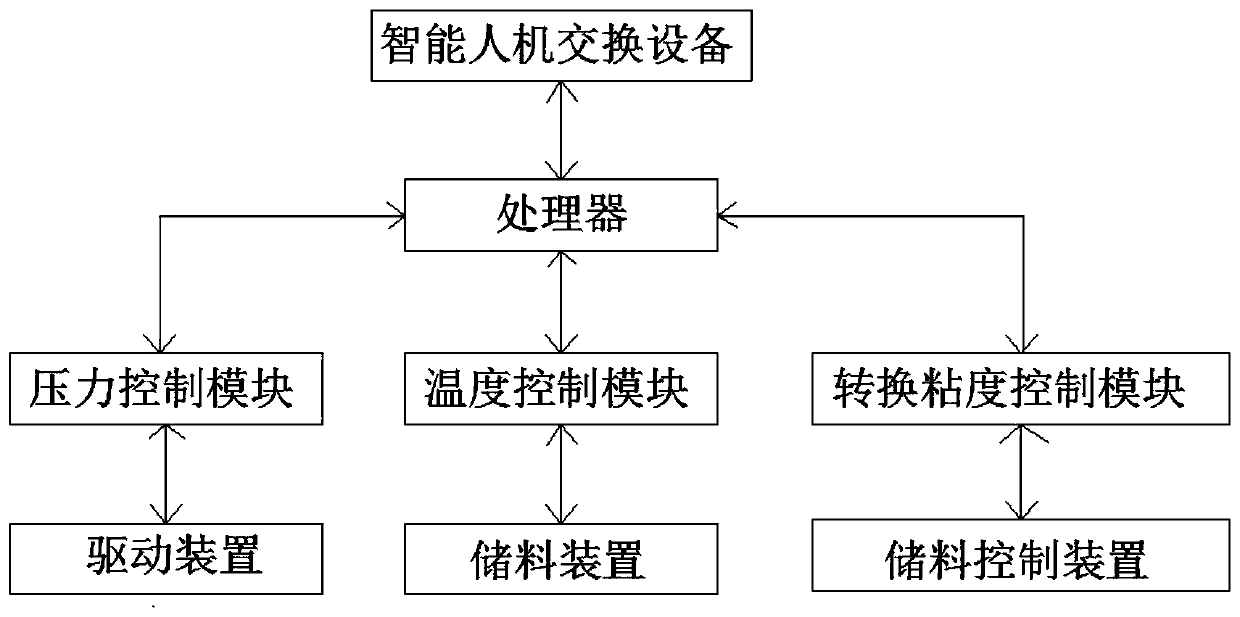

[0082] Please refer to image 3 , the present invention also provides an intelligently controlled 3D printing nozzle, including an intelligent man-machine exchange device and the above-mentioned 3D printing nozzle;

[0083] The processor of the described 3D printing nozzle includes:

[0084] The pressure control module is used to detect the pressure value in the storage device 3 in real time through the pressure sensor 6; and drive the storage control device 2 through the drive device 1 to adjust the compression movement speed of the material in the storage device 3, and then adjust the storage The pressure value in the cavity realizes the flow adjustment of the 3D printing nozzle;

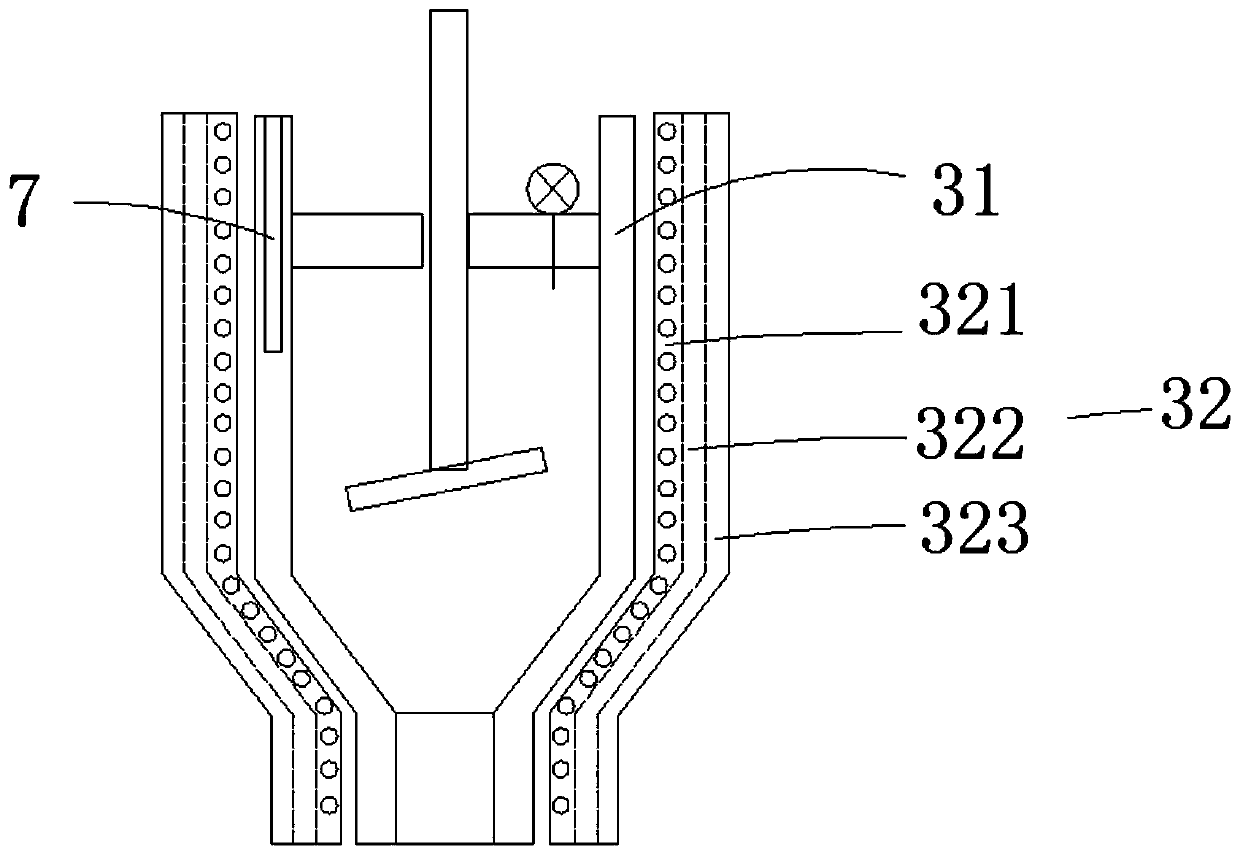

[0085] The temperature control module is used to detect the temperature change in the storage bin 31 in real time through the temperature sensitive probe 7, and output a signal to the induction heating coil in the storage device 3 to adjust the internal temperature of the storage device 3;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com