Concrete release agent prepared from chloroacetic acid modified konjac glucomannan (KGM)

A technology of konjac glucomannan and concrete release agent, which is applied in the field of concrete release agent, can solve the problems such as hindering the adhesion of concrete surface and limitation of application scope, and achieves the effects of high cost performance and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further explained below in conjunction with specific examples.

[0019] A concrete release agent prepared by chloroacetic acid modified konjac glucomannan, KGM and chloroacetic acid undergo a bimolecular nucleophilic substitution reaction in a sodium hydroxide alkaline environment, and the reaction equation is as follows:

[0020] ;

[0021] ;

[0022] Among them: R—sugar residue in KGM.

[0023] Its preparation method is: take KGM purified powder into a beaker filled with 60-75% alcohol solution, add chloroacetic acid, adjust the pH value to 8-9, stir and react at 60 °C for 3-4 hours, and dry to obtain To modify KGM particles, add water and stir to dissolve at a certain temperature, and filter out the sol to obtain a modified solution. Wherein, the molar ratio of KGM purified powder to chloroacetic acid is 1:1.

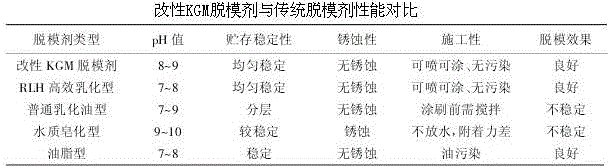

[0024] The performance advantages of the modified KGM release agent of the present invention compared with traditional r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com