A semi-automatic liner-free penetration welding process for steel box columns

A penetration welding and semi-automatic technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems such as unstable quality and low welding efficiency, and achieve the effects of reducing production costs, improving work efficiency, and improving assembly and welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

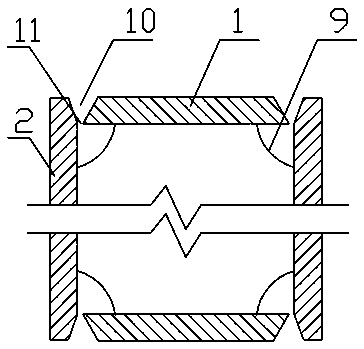

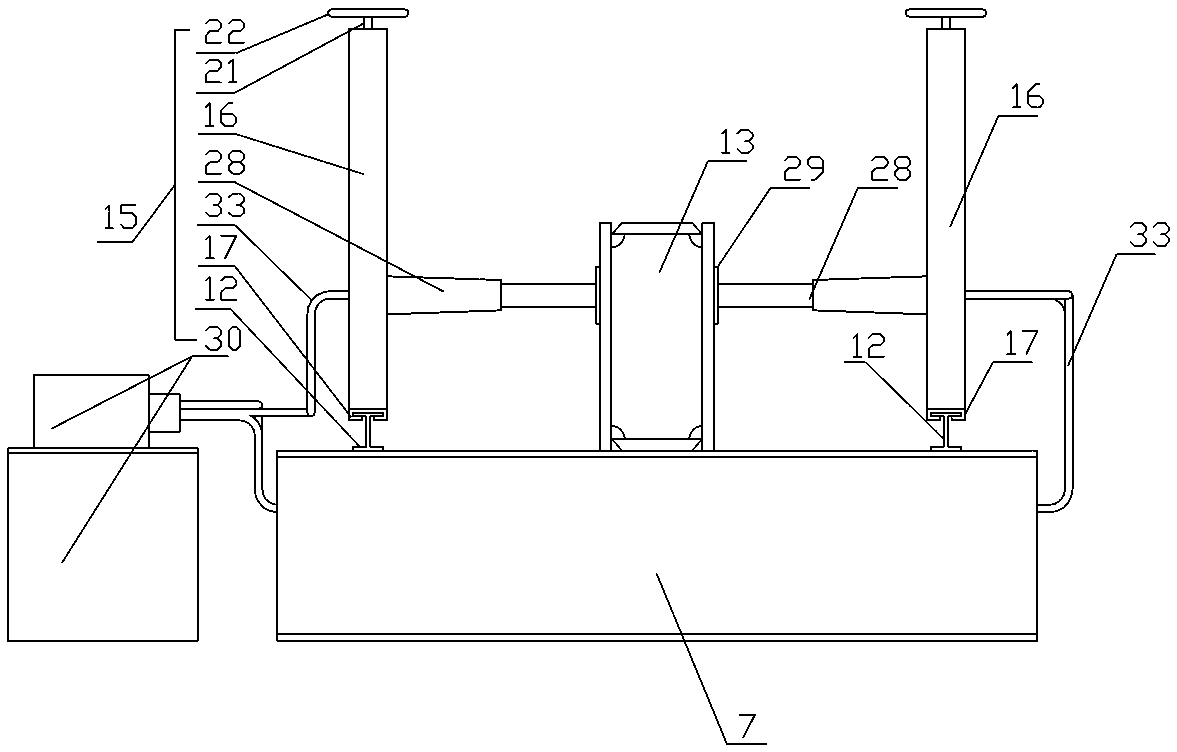

[0031] A semi-automatic liner-free penetration welding process for a steel box column. The steel box column 13 is a frame-shaped structure formed by two webs 1 and two wing plates 2 perpendicular to each other, wherein the web 1 and the wing 2 The length is 3m, and the thickness is 30mm. The welding process of the steel box column 13 is as follows:

[0032] Groove preparation steps before welding: using the flame cutting process, two groove surfaces A3 without blunt edges are symmetrically prepared on both sides of the web 1, and the angle between the groove surface A3 and the left and right side walls of the web 1 α4 is 30°, and two groove surfaces B5 are symmetrically prepared on both sides of the wing plate 2, the angle β6 between the groove surface B5 and the upper and lower surface of the wing plate 2 is 20°, the groove surface A3 and the groove surface B5 The surface uses an angle grinder to remove the oxide layer produced by flame cutting;

[0033] Assembly steps befor...

Embodiment 2

[0040] A semi-automatic liner-free penetration welding process for a steel box column. The steel box column 13 is a frame-shaped structure formed by two webs 1 and two wing plates 2 perpendicular to each other, wherein the web 1 and the wing 2 The length is 10m, and the thickness is 50mm. The welding process of the steel box column 13 is as follows:

[0041] Groove preparation steps before welding: using the flame cutting process, two groove surfaces A3 without blunt edges are symmetrically prepared on both sides of the web 1, and the angle between the groove surface A3 and the left and right side walls of the web 1 α4 is 25°, and two groove surfaces B5 are symmetrically prepared on both sides of the flange 2, the angle β6 between the groove surface B5 and the upper and lower surface of the flange 2 is 15°, the groove surface A3 and the groove surface B5 The surface uses an angle grinder to remove the oxide layer produced by flame cutting;

[0042] Assembly steps before weldi...

Embodiment 3

[0048] A semi-automatic liner-free penetration welding process for a steel box column. The steel box column 13 is a frame-shaped structure formed by two webs 1 and two wing plates 2 perpendicular to each other, wherein the web 1 and the wing 2 The length is 18m, and the thickness is 80mm. The welding process of the steel box column 13 is as follows:

[0049] Groove preparation steps before welding: using the flame cutting process, two groove surfaces A3 without blunt edges are symmetrically prepared on both sides of the web 1, and the angle between the groove surface A3 and the left and right side walls of the web 1 α4 is 20°, and two groove surfaces B5 are symmetrically prepared on both sides of the wing plate 2. The angle β6 between the groove surface B5 and the upper and lower surface of the wing plate is 10°, and the surface of the groove surface A3 and the groove surface B5 Use an angle grinder to remove the oxide layer produced by flame cutting;

[0050] Assembly steps ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com