A kind of allophane silicon nanotube hybrid forward osmosis membrane

A technology of silicon nanotubes and allophane, applied in the field of membrane separation, can solve problems such as cumbersome operation steps, achieve the effects of reducing internal concentration polarization and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

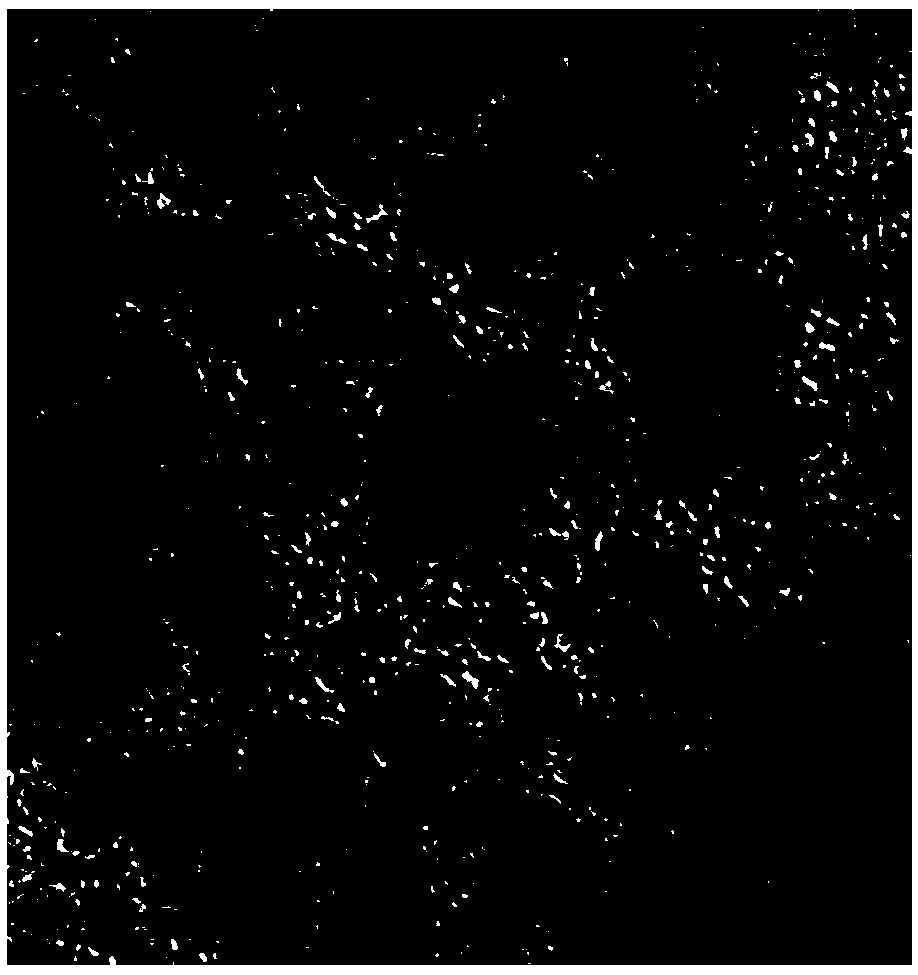

Embodiment 1

[0022] Polysulfone and allophane silicon nanotubes with a mass ratio of 4.5:0.1:25 (such as figure 1 Shown), N,N-dimethylacetamide mixed, first under the ultrasonic frequency of 80KHz for 30min, then stirred and dissolved at 80°C for 6h to form a uniform solution, after standing for 12h to obtain the casting solution, through the film forming Machining and molding to form a primary film, within 10 minutes after forming, immerse in an aqueous solution with a mass percentage of 0.2% N,N-dimethylacetamide at 20°C for 24 hours; immerse the obtained basement film in a mass percentage of 2% m-phenylenediamine aqueous solution for 1 min, drain the aqueous solution, and then transfer to a hexane solution of 1% trimesoyl chloride for 1 min, remove the excess solution on the membrane surface, and place the membrane in a 60°C oven Heating in medium temperature for 40min to obtain allophane-silicon nanotube hybrid polysulfone forward osmosis membrane.

[0023] The pure water flux of the ...

Embodiment 2

[0026] Mix polysulfone, allophane silicon nanotubes, and N,N-dimethylacetamide with a mass ratio of 4.5:0.2:25, first place it under ultrasonic waves at a frequency of 80KHz for 30min, then stir and dissolve at 80°C for 6h to form a uniform The solution was left to defoam for 12 hours to obtain the casting solution, which was processed by a film forming machine to form a nascent film, and entered into an aqueous solution with a mass percentage of 0.2% N,N-dimethylacetamide within 10 minutes after forming Immerse for 24 hours; immerse the obtained basement film in an aqueous solution of 2% m-phenylenediamine by mass for 1 min, drain the aqueous solution, and then transfer it to a hexane solution of trimesoyl chloride with a mass percentage of 1% After removing excess solution on the surface of the membrane for 1 min, the membrane was heated in an oven at 60° C. for 40 min to obtain an allophane silicon nanotube hybrid polysulfone forward osmosis membrane.

[0027] The measureme...

Embodiment 3

[0029] Mix polysulfone, allophane silicon nanotubes, and N,N-dimethylacetamide with a mass ratio of 4.5:0.3:25, first place it under ultrasonic waves at a frequency of 80KHz for 30min, then stir and dissolve at 80°C for 6h to form a uniform After standing for degassing for 12 hours, the casting solution was obtained, and processed by a film forming machine to form a nascent film, and immersed in an aqueous solution with a mass percentage of 0.2% N,N-dimethylacetamide within 10 minutes after forming 24h; Immerse the obtained basement film in an aqueous solution of 2% m-phenylenediamine by mass for 1 min, drain the aqueous solution, and then transfer it to a hexane solution of 1% by mass of trimesoyl chloride for 1 min , after removing excess solution on the membrane surface, the membrane was heated in an oven at 60° C. for 40 minutes to obtain an allophane silicon nanotube hybrid polysulfone forward osmosis membrane.

[0030] The measurement results are: the pure water flux of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com