Automatic adjustment row-controlled device of peanut combine

A combine harvester and automatic adjustment technology, which is applied in the direction of digging harvesters, harvesters, agricultural machinery and implements, etc., can solve the problems of high operating cost, lack of mature technology, and large loss of missed harvest, so as to improve operating efficiency, Improve the quality of harvest and reduce the effect of missed harvest

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

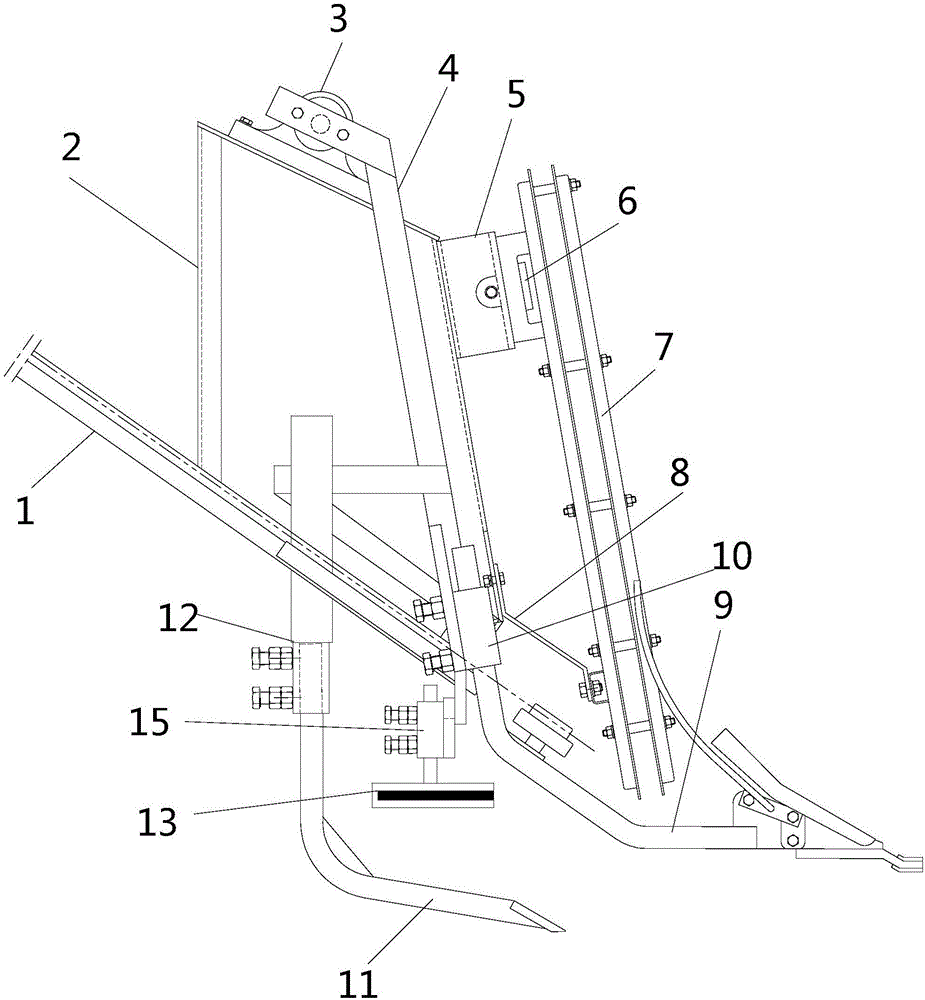

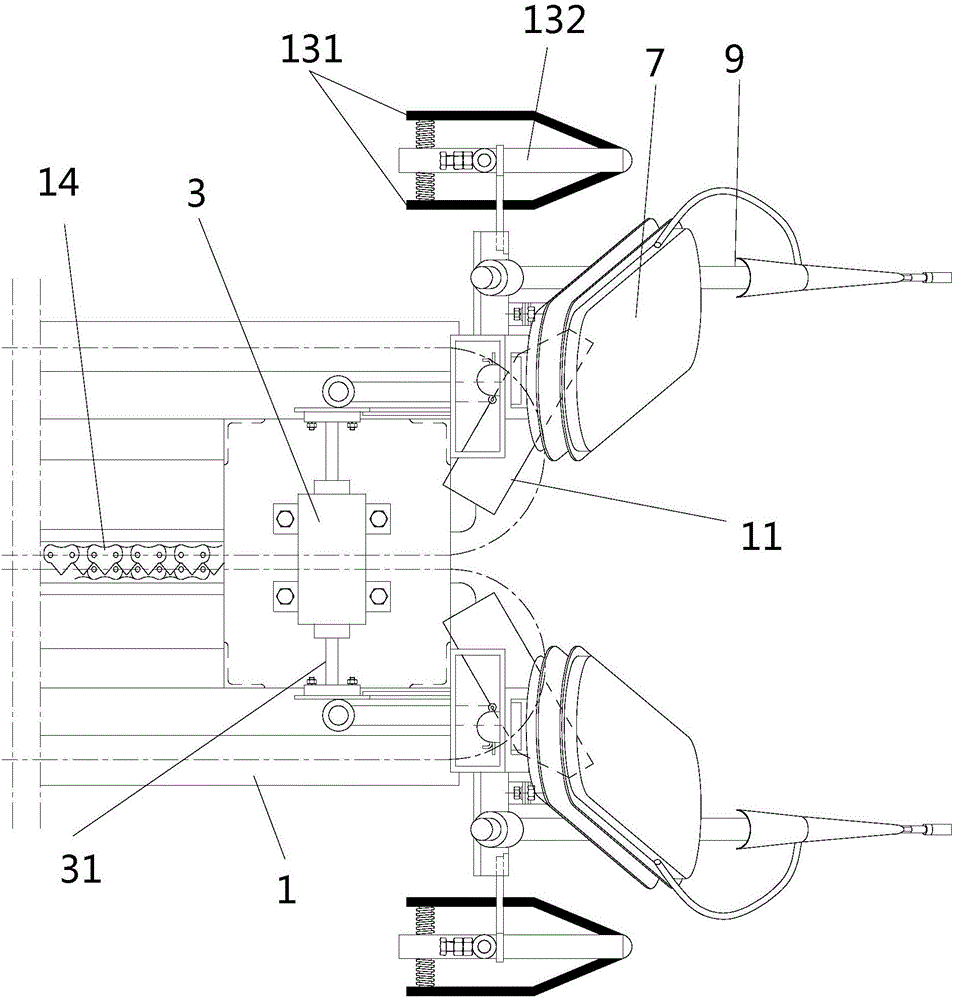

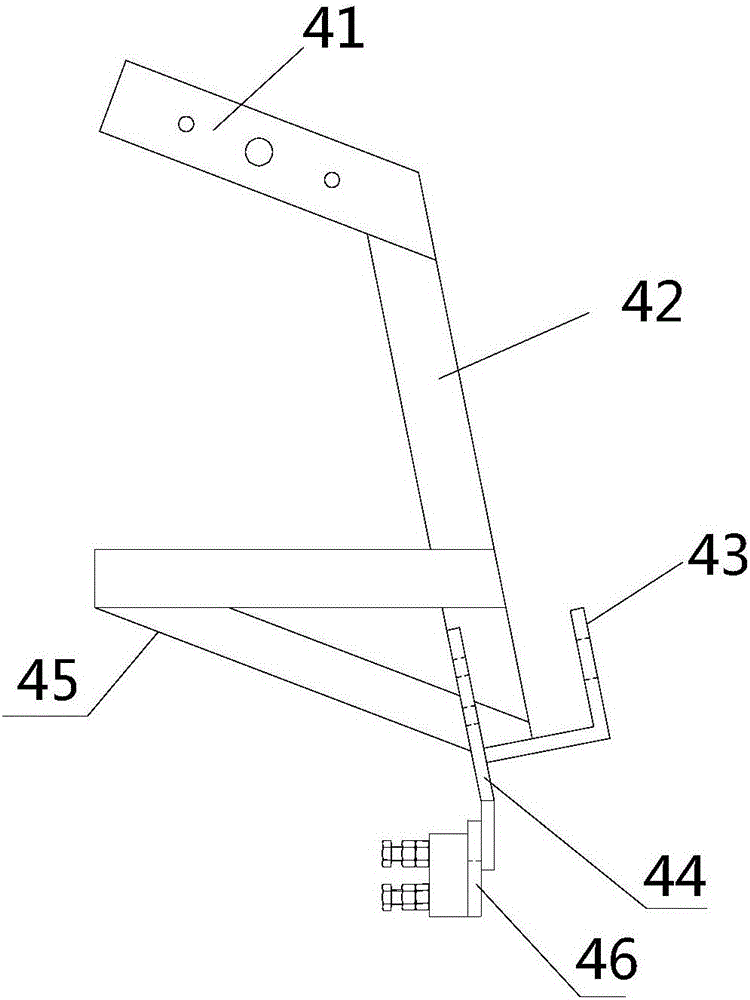

[0020] see Figure 1 to Figure 3 , this embodiment discloses an automatic adjustment device for a peanut combine harvester, including a support frame 2 fixedly arranged on the frame 1 of the harvester, and a position adjustment electric cylinder 3 is arranged on the support frame 2, and the position adjustment electric cylinder 3 is arranged on the support frame 2. Cylinder 3 is a double-acting electric cylinder. The left and right ends of the telescopic rod 31 of the position-adjusting electric cylinder 3 protrude outwards along the left and right sides respectively and are fixedly connected with corresponding mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com