Instant tube heater with homogenous temperature control

A tube heater, temperature sensor technology, applied in water heaters, fluid heaters, devices for controlling liquid flow, etc. Improvement, overall efficiency improvement, accurate temperature sensing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The following description will be given with reference to the above-mentioned drawings.

[0058] The terms "inlet", "outlet", "inlet", "outlet", "upstream" and "downstream" are used herein to indicate the configuration of the device by reference to the relative significance of the flow of liquid during operation of the tube heater .

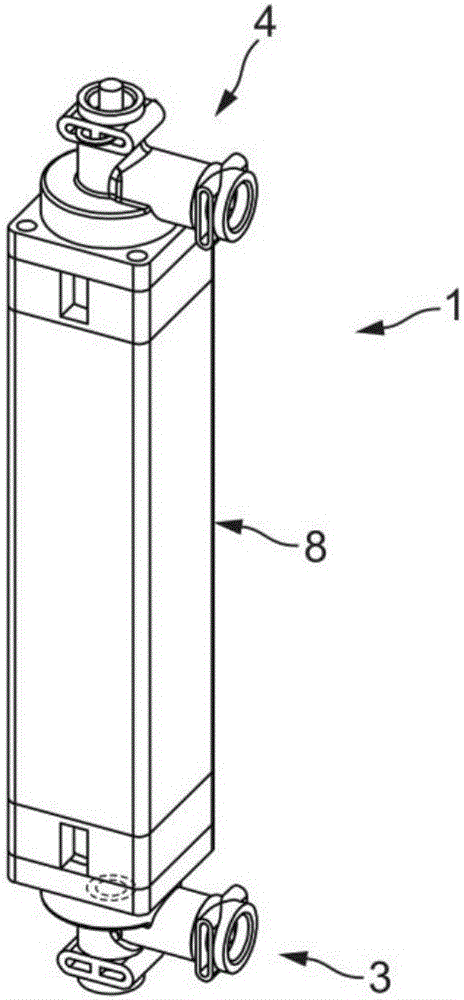

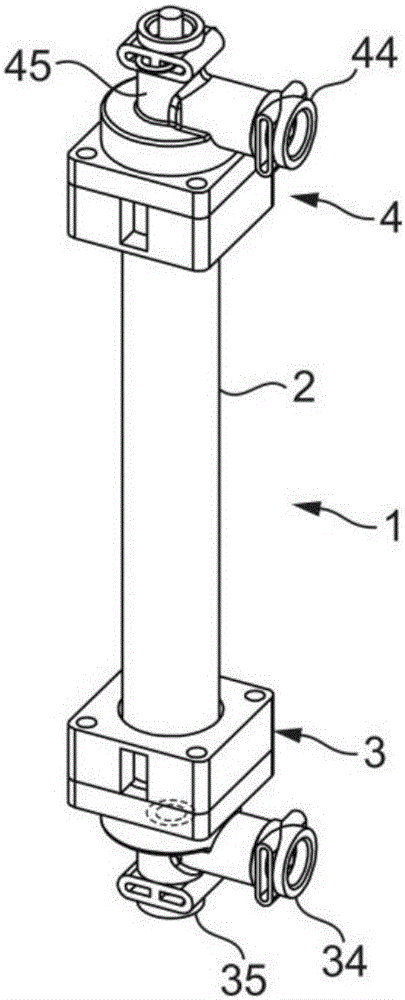

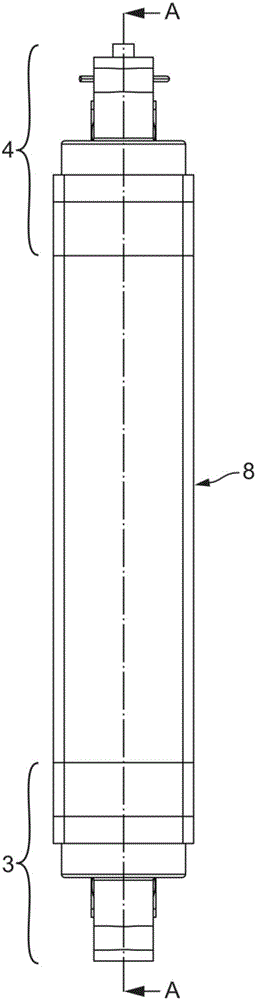

[0059] The instant tube heater 1 of the present invention generally comprises a hollow heating tube 2 , an inlet connector 3 and an outlet connector 4 . Both the inlet connector and the outlet connector are arranged for fluid communication of the heater with an external flow duct (not represented) of the beverage preparation machine. The inlet connector 3 is preferably sealingly connected to the inlet end 21 of the hollow heating tube 2 . Similarly, the outlet connector 4 is sealingly connected to the outlet end 22 of the heating tube.

[0060] The connection between the inlet connector 3 and the outlet connector 4 and the tube 2 may be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com