Method for preparing high-quality perovskite thin film by introducing cheap additive

An additive preparation, high-quality technology, used in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve problems such as limiting the development of perovskite cells, diversity affecting quality, and destroying device stability. Application prospect, improvement of film morphology, and effect of improving optoelectronic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

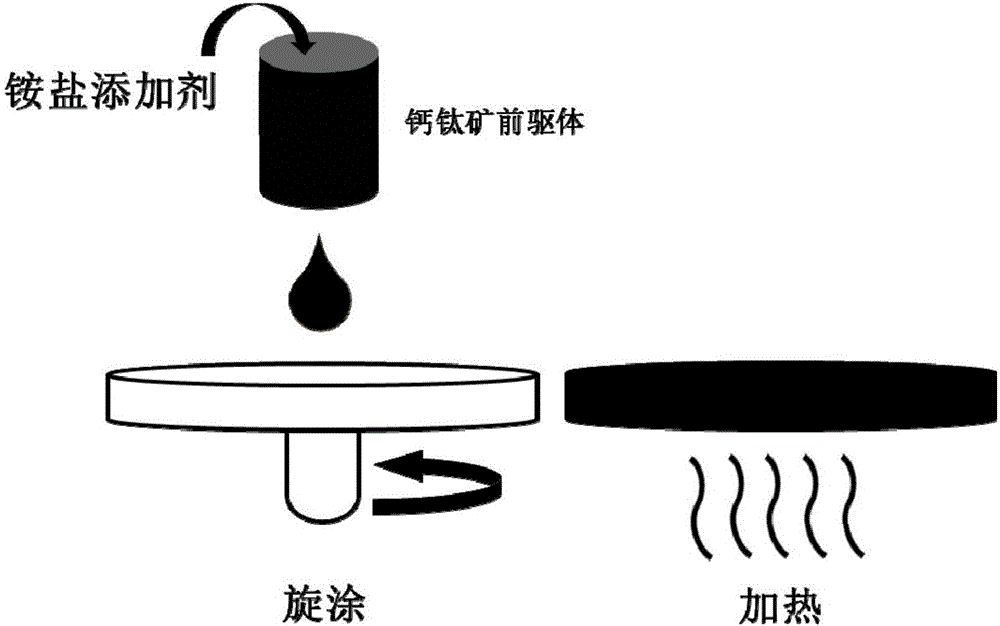

[0053] Example 1: Introducing cheap NH 4 I Preparation of high-quality perovskite thin films

[0054] The substrate (FTO / ITO) was cleaned, and ethanol, acetone, and isopropanol were alternately ultrasonicated for 15 minutes, and dried with nitrogen gas for later use. The cleaned substrate was etched by oxygen plasma for 15 minutes. Configure perovskite precursor solution, mix 1:1 CH 3 NH 3 I(MAI) and PbI 2 Dissolve in a mixed solvent of dimethyl sulfoxide and dimethylformamide, add 1% NH 4 I get the precursor solution. The precursor solution is spin-coated onto the treated substrate in one step, the spin-coating speed is 2000 rpm, and the operation is performed under the condition that the humidity is lower than 30%. The preparation method of the perovskite thin film without ammonium salt additive is the same as above. Spin-coat the hole-transport material and evaporate the gold electrode. test.

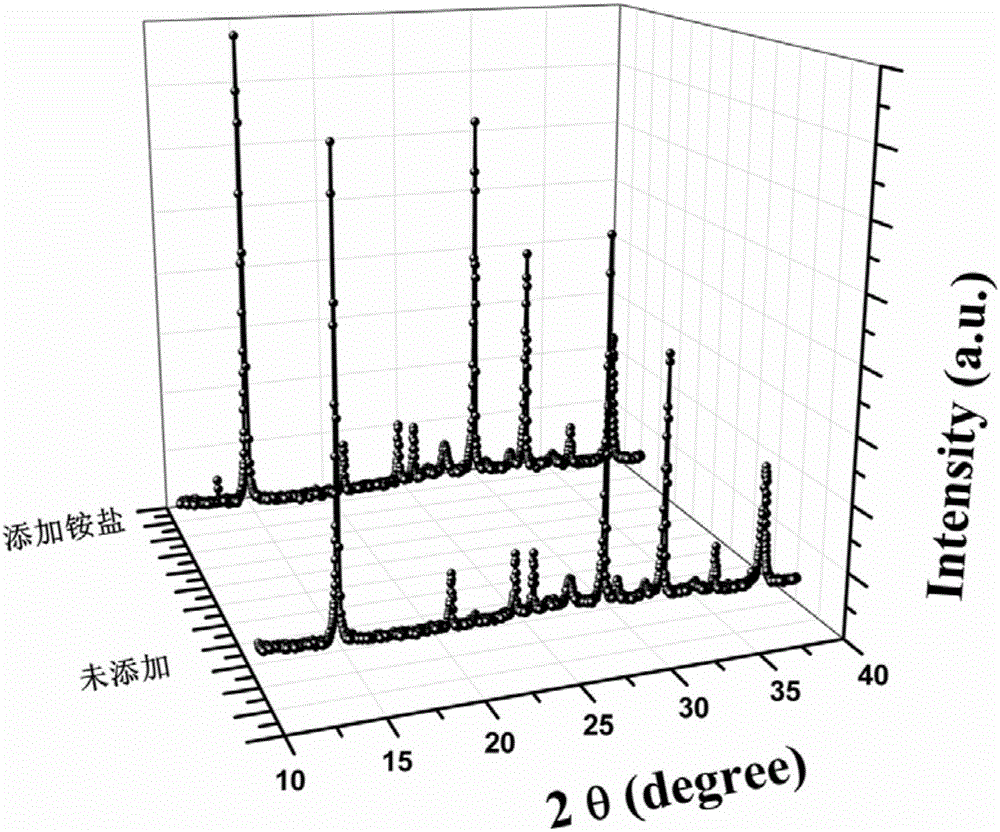

[0055] Compare the X-ray diffraction patterns of perovskite before and ...

example 2

[0058] Example 2: Introducing cheap NH 4 Preparation of high-quality perovskite thin films by Cl

[0059] The substrate (FTO / ITO) was cleaned, and ethanol, acetone, and isopropanol were alternately ultrasonicated for 15 minutes, and dried with nitrogen gas for later use. The cleaned substrate was etched by oxygen plasma for 15 minutes. To configure the perovskite precursor solution, mix 1:1 NH 2 -CH=NH 2 I(FAI) and PbI 2 Dissolve in a mixed solvent of dimethyl sulfoxide and dimethylformamide, add 15% NH 4 Cl to obtain the precursor solution. The precursor solution is spin-coated onto the treated substrate in one step, the spin-coating speed is 2000 rpm, and the operation is performed under the condition that the humidity is lower than 30%. The preparation method of the perovskite thin film without ammonium salt additive is the same as above. Spin-coat the hole-transport material and evaporate the gold electrode. test.

[0060] Comparing the performance diagram of pero...

example 3

[0061] Example 3: Introducing cheap NH 4 Preparation of high-quality perovskite thin films by Br

[0062] The substrate (FTO / ITO) was cleaned, and ethanol, acetone, and isopropanol were alternately ultrasonicated for 15 minutes, and dried with nitrogen gas for later use. The cleaned substrate was etched by oxygen plasma for 15 minutes. Configure perovskite precursor solution, mix 1:1 CH 3 NH 3 Cl and PbI 2 Dissolve in a mixed solvent of dimethyl sulfoxide and dimethylformamide, add 5% NH 4 Br to get the precursor solution. The precursor solution is spin-coated onto the treated substrate in one step, the spin-coating speed is 2000 rpm, and the operation is performed under the condition that the humidity is lower than 30%. The preparation method of the perovskite thin film without ammonium salt additive is the same as above. Spin-coat the hole-transport material and evaporate the gold electrode. test.

[0063] Comparing the performance diagram of perovskite battery befo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com