Extraction chromatography separation device applicable to manipulator operation in hot chamber

A chromatographic separation and manipulator technology, used in material separation, separation methods, measuring devices, etc., can solve problems such as easy failure, easy aging and decomposition, and inability to maintain, reduce space occupation, reduce operation difficulty, and facilitate access. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further elaborated below in combination with the accompanying drawings and specific embodiments.

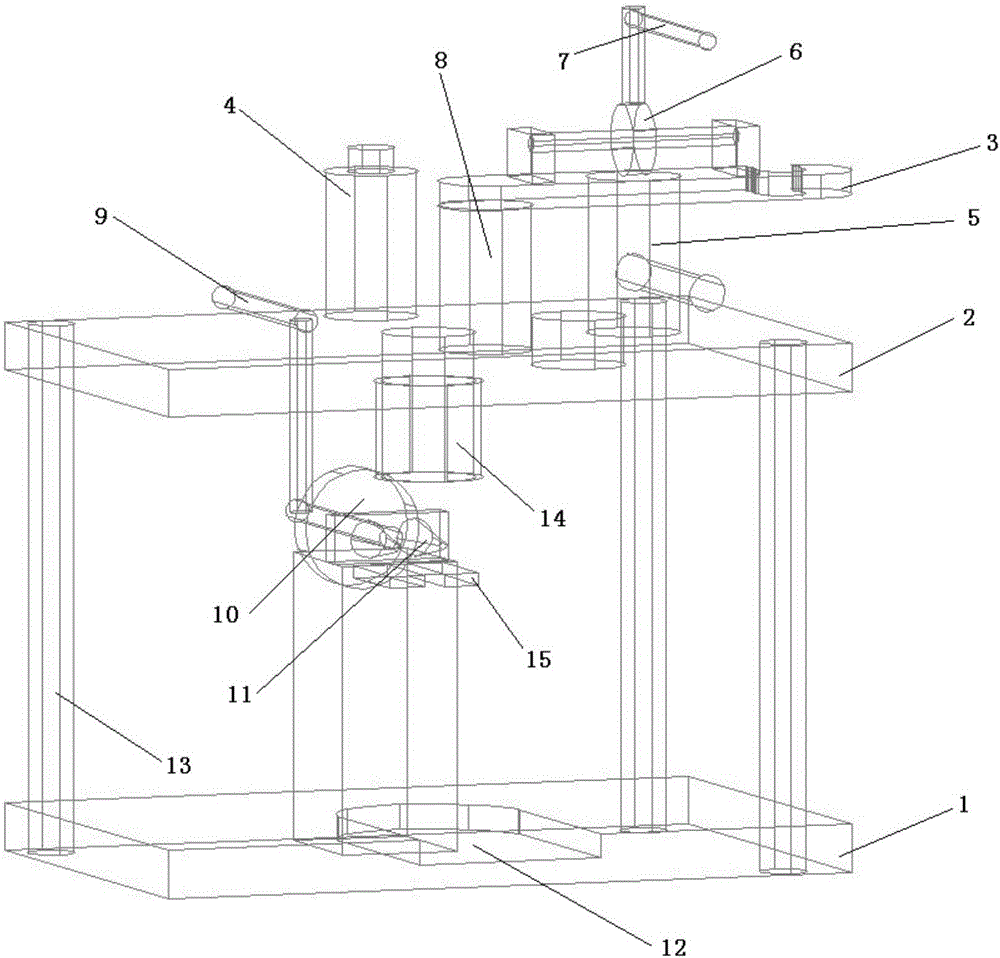

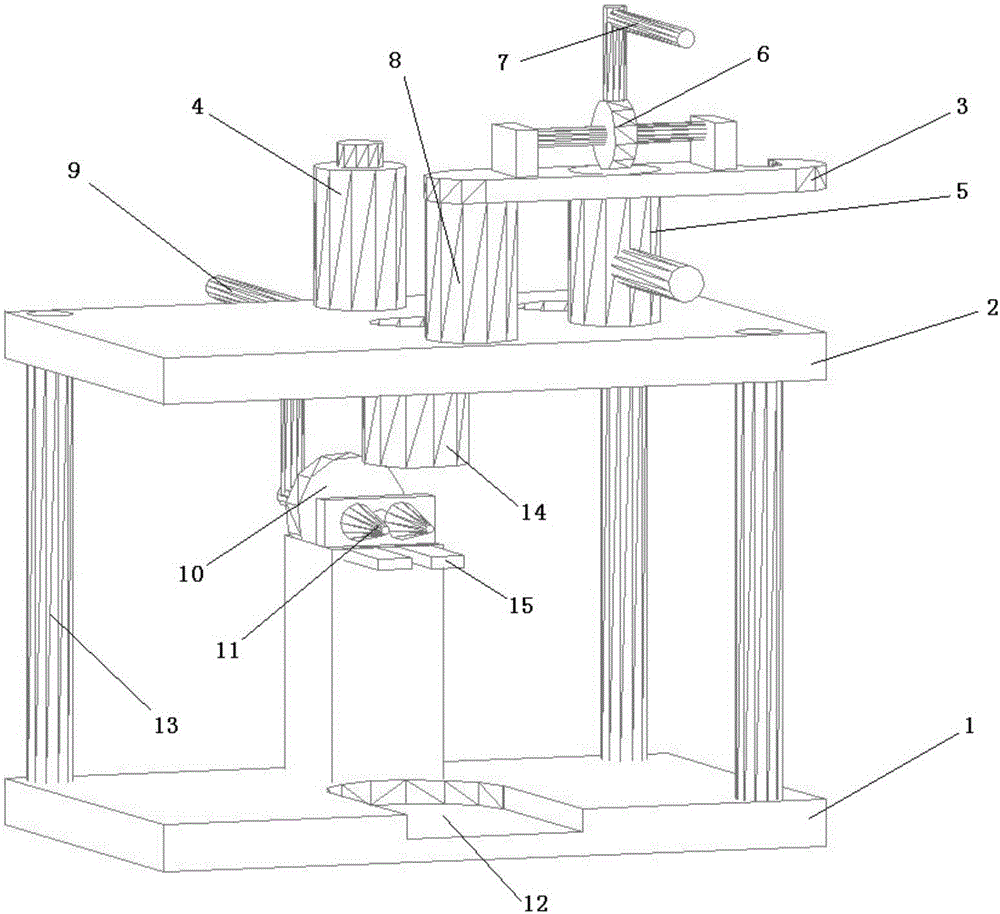

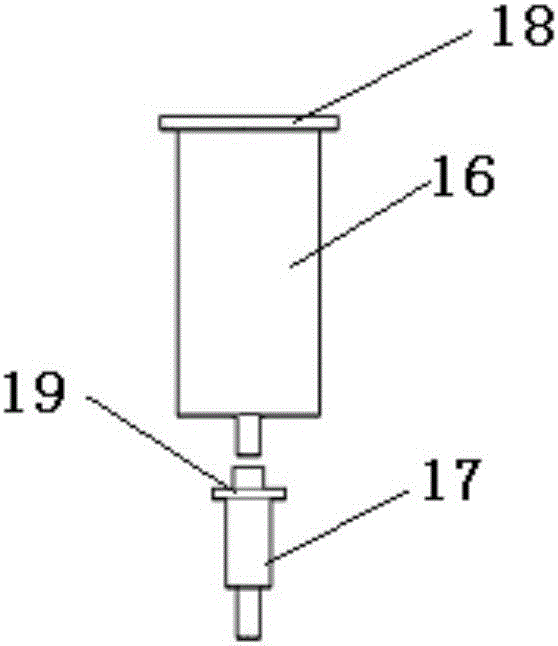

[0031] An extraction chromatography apparatus suitable for use in a hot chamber, such as Figure 1 ~ Figure 3 As shown, the device includes a base plate 1, a top plate 2, a rotating cover plate 3, a limit device 4, an eccentric wheel pressing device, a liquid storage tube, a separation column, a column tube alignment device and a plug-in separation device, wherein the top plate 2 is located at Three support columns 13 are arranged above the base plate 1 and between them; the rotating cover plate 3 is located above the top plate 2 and two columns are arranged between them; 4. The eccentric wheel pressing device, column tube alignment device and plug-in separation device are all made of stainless steel. A silica gel sheet for increasing friction is arranged under the bottom plate 1 .

[0032] The bottom plate 1 is provided with a limiting groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com