Dual extreme value response surface method for calculating leaf disc vibration reliability

A response surface method and reliability technology, applied in calculation, computer-aided design, complex mathematical operations, etc., can solve problems such as large amount of calculation, low efficiency, unsatisfactory accuracy and efficiency, etc., to reduce calculation cost and facilitate use , The effect of convenient ANSYS analysis function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

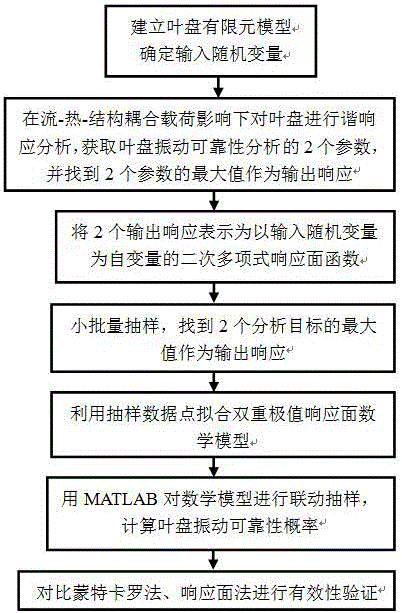

[0025] A double extremum response surface method for calculating the reliability of blade disk vibration, comprising the following steps:

[0026] a. Determine the factors that affect the reliability of the blisk vibration;

[0027] b. Analyze the transfer process of fluid-thermal-structural coupling load among the influencing factors;

[0028] c. Perform vibration modal analysis and harmonic response analysis on the blade disk under the influence of flow-heat-structure coupling load to obtain the basic parameters of blade disk vibration reliability analysis;

[0029] d. Construct the mathematical model of the dual extreme value response surface method for the reliability analysis of the blisk vibration;

[0030] e. Analyze the vibration reliability of the blisk by using the dual extreme value response surface method;

[0031] f. Verify the validity of the dual extreme value response surface method.

Embodiment 2

[0033] According to the dual extreme value response surface method for calculating the vibration reliability of the blisk described in embodiment 1, in the step a, according to the analysis of the vibration failure of the blisk of the engine, determine the external load factors and the structure itself that affect the vibration reliability of the blisk parameter.

Embodiment 3

[0035] According to the double extremum response surface method for calculating the vibration reliability of the blisk described in embodiment 1, in the step b, the aerodynamic pressure data obtained by the fluid analysis is transmitted to the blisk structure through the interpolation method using the internal program of the ANSYS software, Use the element shape function and element node displacement to obtain the value required for the analysis object, use it as the input load, transfer it to the temperature field through the interface of the finite element software, and use the finite volume method to conduct flow-thermal coupling analysis; according to Fourier's heat conduction law and energy Conservation law, establish a three-dimensional heat conduction equation, conduct thermal analysis on the blisk combined with heat convection Newton cooling equation, and then use the finite element method to transfer the obtained coupling interface load data to the blisk structure, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com