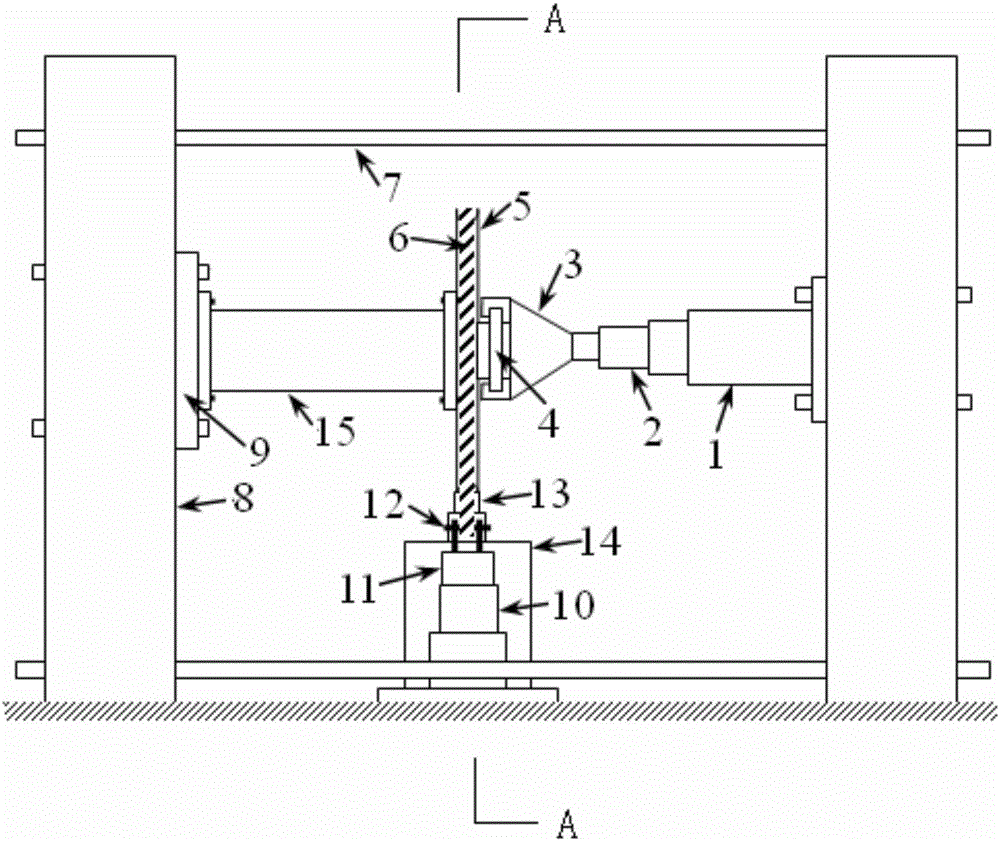

Hollow interlayer steel pipe concrete column tension-torsion test loading device

A steel tube concrete column and loading device technology, applied in the direction of measuring device, using stable torsion to test material strength, using stable tension/pressure to test material strength, etc., can solve problems such as inconstant torque variation law, and achieve compliance with Good, constant torque variation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

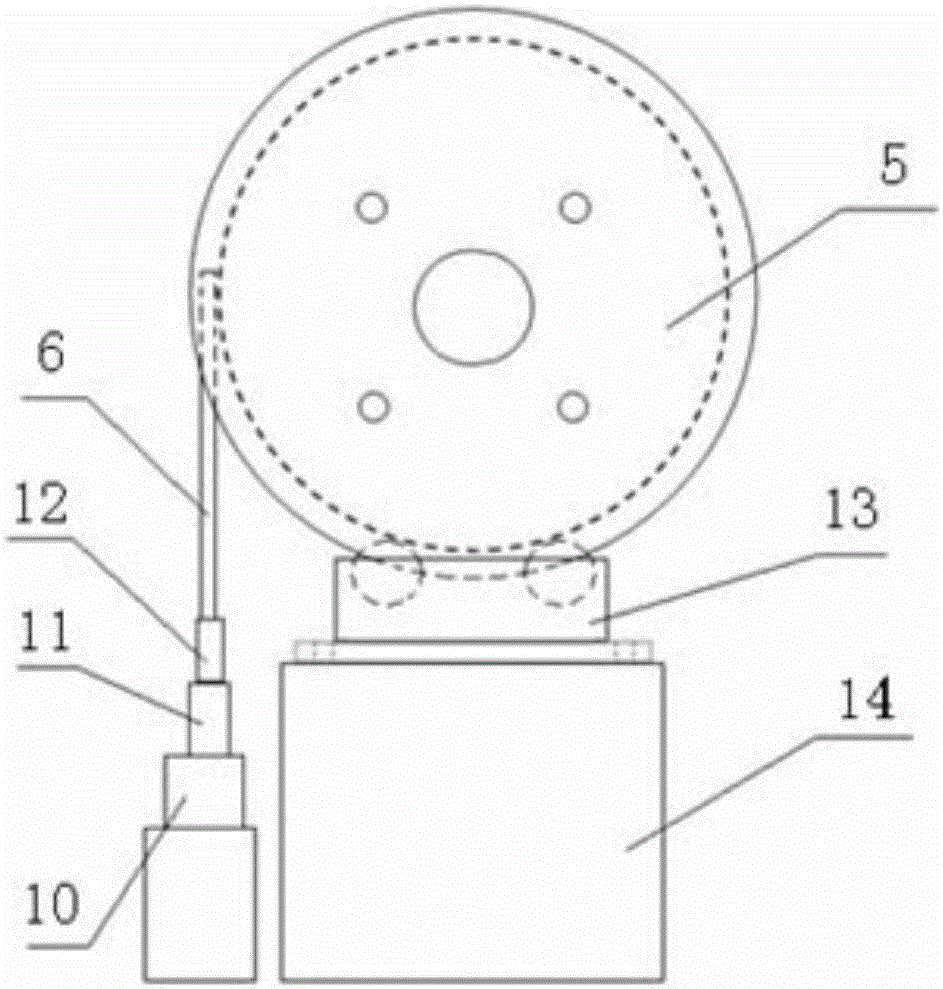

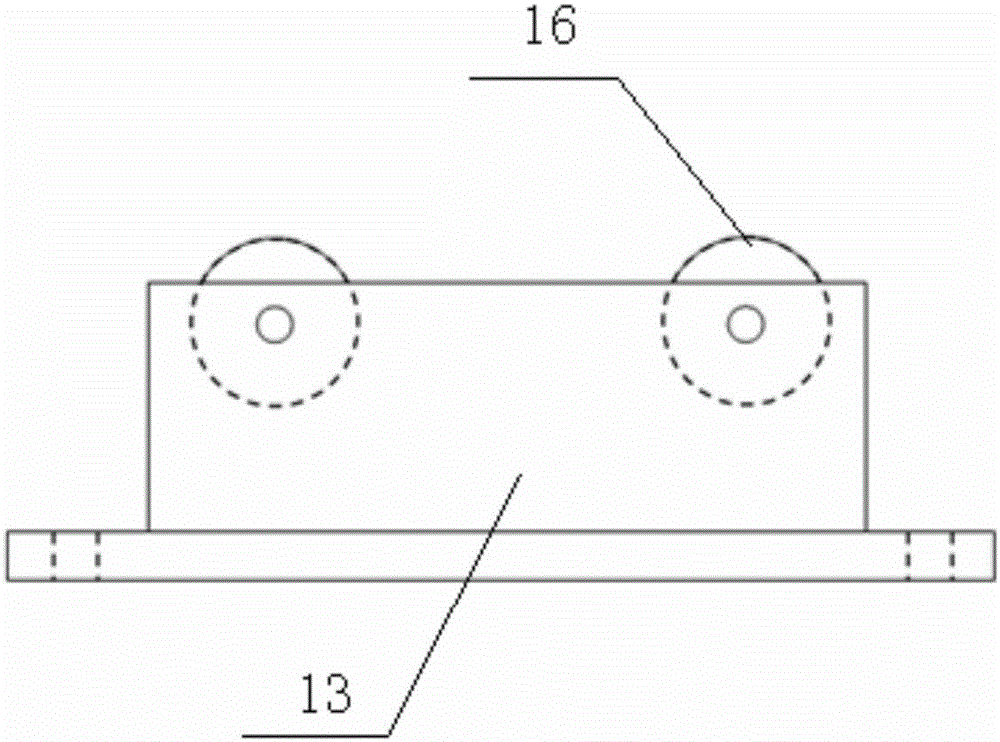

[0012] like Figure 1~4 As shown, a hollow interlayer concrete-filled steel tube column tension-torsion test loading device includes a reaction pier 8, four pressure rods 7, a connecting plate 9, a disc 5, a horizontal tension jack 1, a horizontal tension sensor 2, a tension bearing 3, Horizontal tension connector 4, roller support 13, pedestal 14, vertical tension jack 10, vertical tension sensor 11, vertical tension connector 12 and steel wire rope 6; two reaction piers 8 are fixed on the ground, two reaction piers The force pier 8 is connected together by four pressure rods 7; the connecting plate 9, the hollow interlayer concrete filled steel pipe column 15 and the disc 5 are fixedly connected together, and the connecting plate 9 and the horizontal tension jack 1 are respectively fixed on two On a reaction pier 8, its axis remains at the same horizontal position, and the horizontal tension jack 1 is connected together with the said disk 5 through the horizontal tension sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com