Dynamic radial deformation and dynamic tension monitoring device of deep-well double-broken-line-type multi-layer winding elevator steel wire rope and method thereof

A technology of radial deformation and monitoring device, applied in measuring devices, instruments, etc., can solve the problems of inability to accurately calculate the wire rope tension, low accuracy of the three-point bending method, inability to measure the wire rope tension value, etc., so as to reduce mining accidents. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further explained below in conjunction with the accompanying drawings.

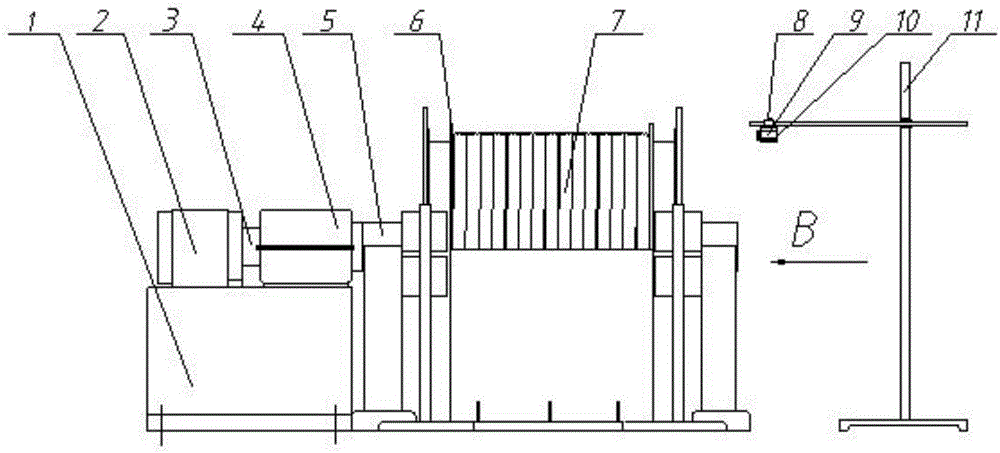

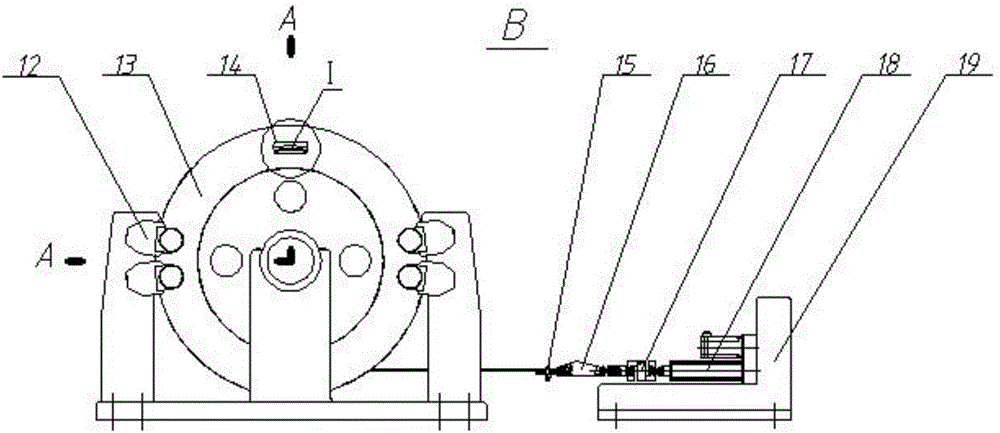

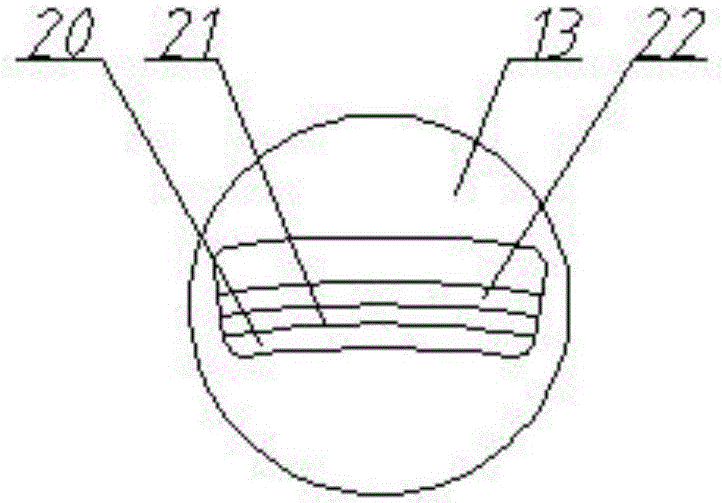

[0032] like figure 1 and 2 As shown, a device for monitoring dynamic radial deformation and dynamic tension of a steel wire rope of a deep well double broken line type multilayer winding hoist according to the present invention includes a base frame, a drive system, a tension and compression detection system, and a dynamic deformation monitoring system.

[0033] The base frame includes a motor and reducer bracket 1 , a servo electric cylinder bracket 19 , a two-dimensional laser sensor fixture 10 and a two-dimensional laser sensor bracket 11 . The motor and reducer bracket 1 and the servo electric cylinder bracket 19 are fixed on the ground through anchor bolts, and the two-dimensional laser sensor fixture 10 is fixed on the two-dimensional laser sensor bracket 11 through bolts A8.

[0034] The drive system includes a motor 2, a shaft coupling A3, a speed reducer 4, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com