Universal testing machine

A measuring instrument and measuring device technology, which is applied in the direction of testing the hardness of materials and testing the strength of materials by applying stable tension/pressure, which can solve the problems of decreased accuracy of displacement measurement, error of measurement results, error of displacement measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

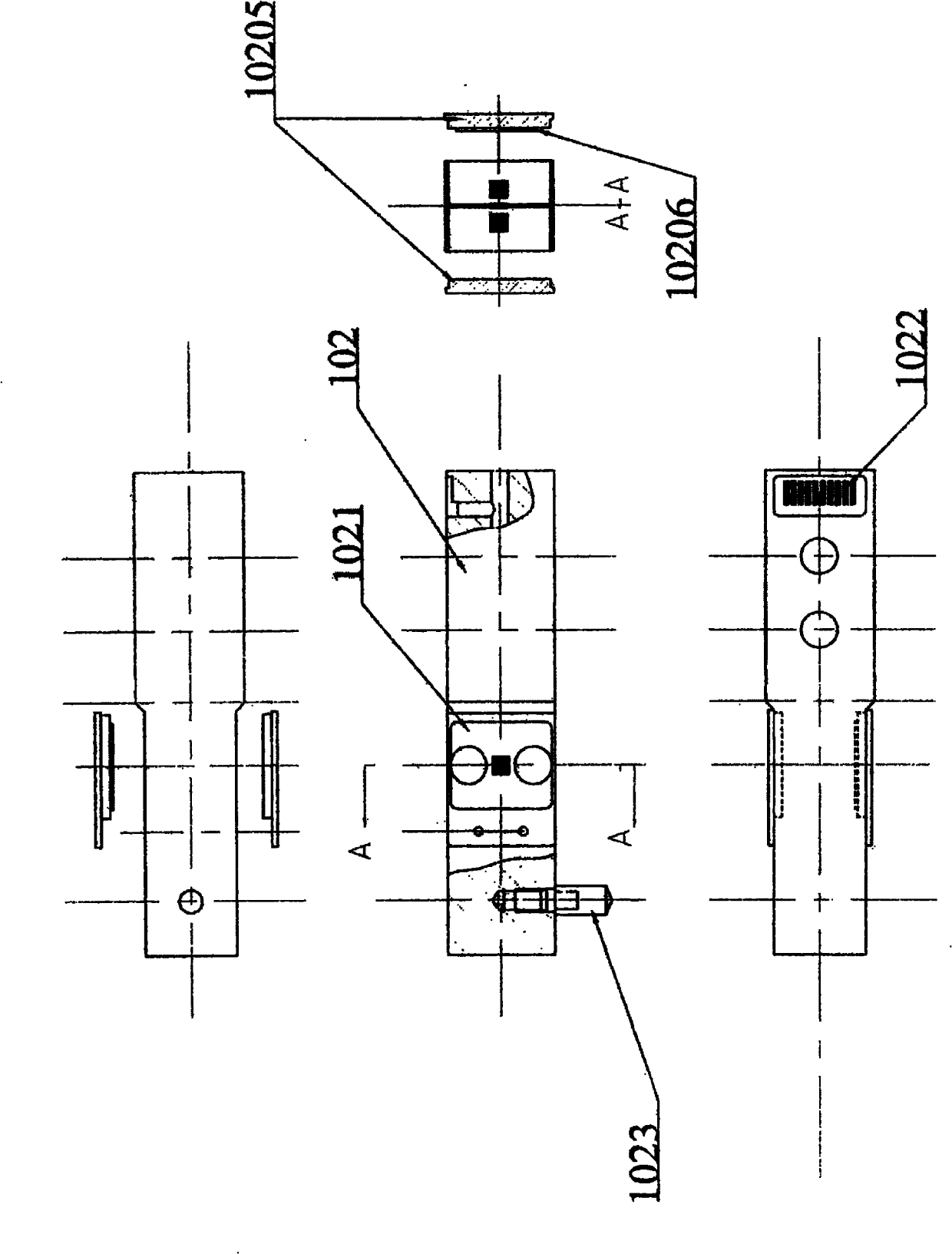

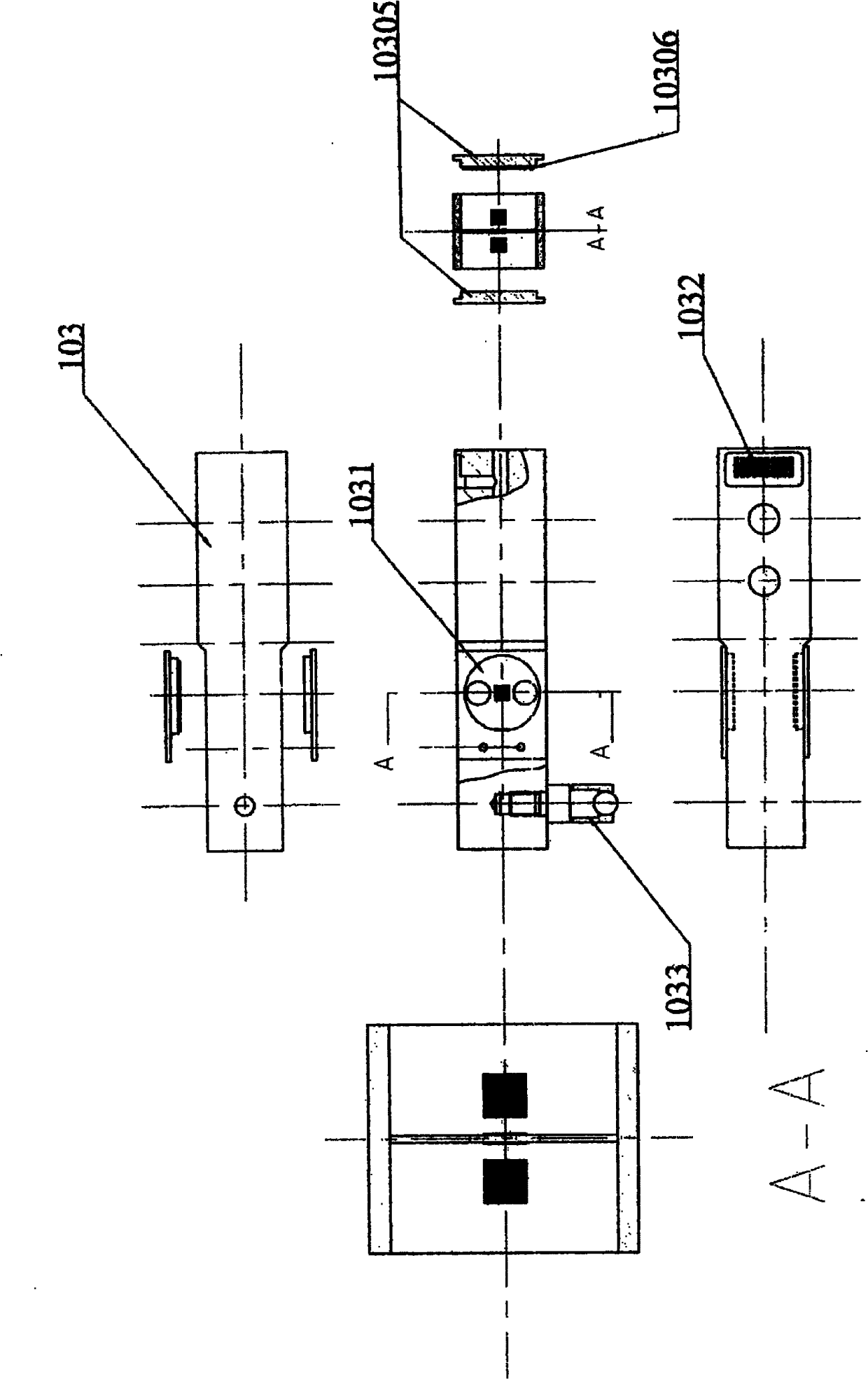

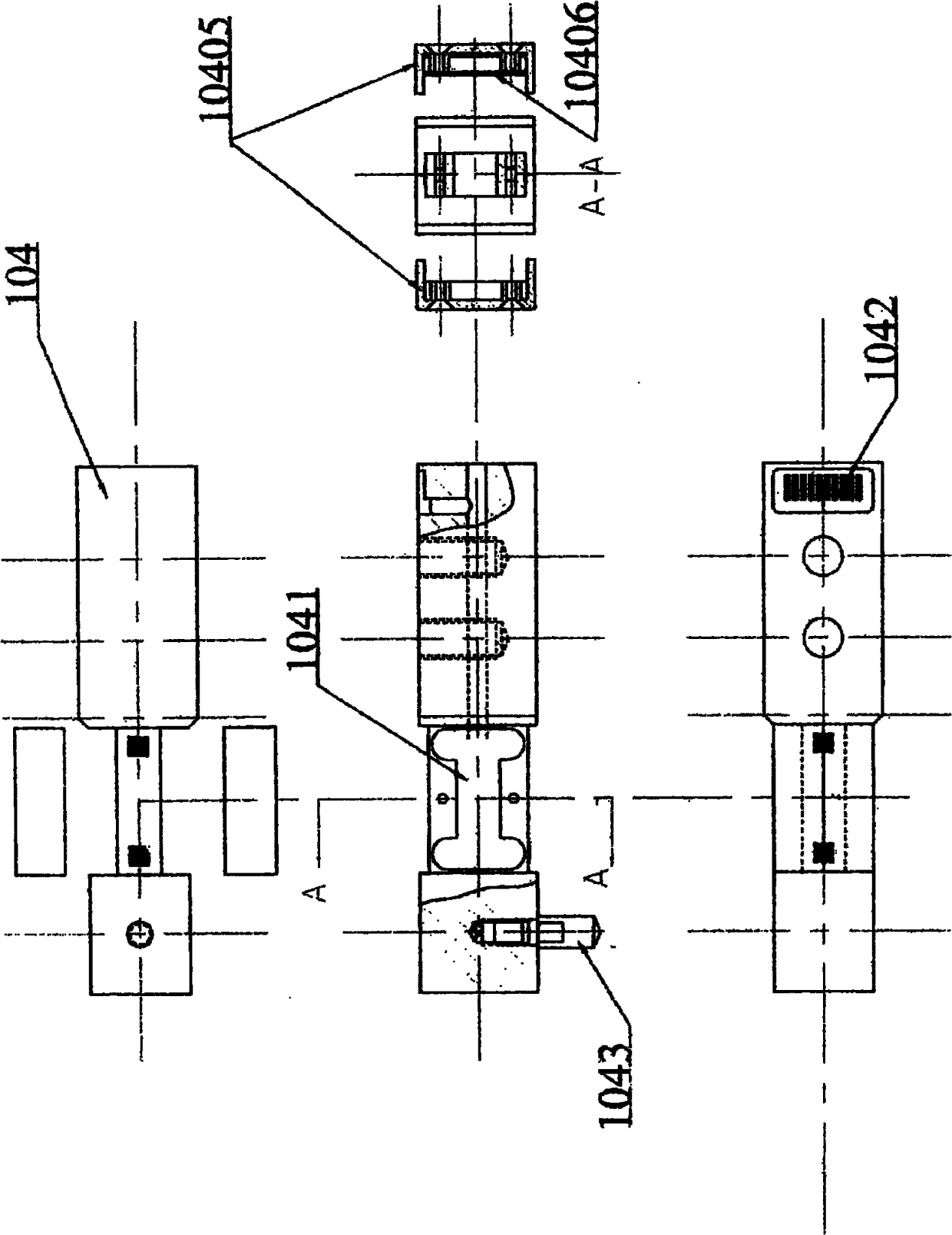

[0055] now refer to figure 1 The inventive meter is described. Such as figure 1 As shown, the measuring instrument of the present invention includes a set of components, which includes a base 1 and a box-shaped frame 2 . The box-shaped frame 2 is fixed on the base 1, and the base 1 is the structural basis of the measuring instrument. The movement of the sliding device 3 is accomplished by controlling an AC servo motor 9 installed at the bottom of the box frame 2 . The AC servo motor 9 drives the threaded ball screw 6 . A pair of sliding shafts 4 straddles both sides of the ball screw 6 . The slide 3 is fitted with linear motion ball bearings or sliding elements 5 which allow the slide 3 to move vertically along the slide axis 4 . The slide device 3 is driven by a ball screw 6 .

[0056] The AC servo motor 9 is tightly connected with the ball screw 6 through a coupling 16 . The ball screw 6 is mounted on the box frame 2 through bearings 14 and 15 .

[0057] The ball nut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com