Buffering device arranged in shock absorber

A technology of buffer device and shock absorber, applied in the direction of shock absorber, spring/shock absorber, shock absorber, etc. Guarantee the service life, improve work efficiency, and the effect of good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

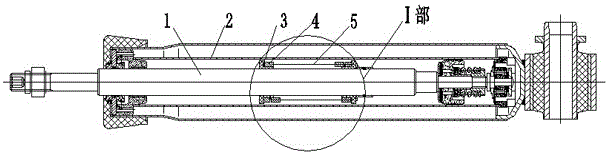

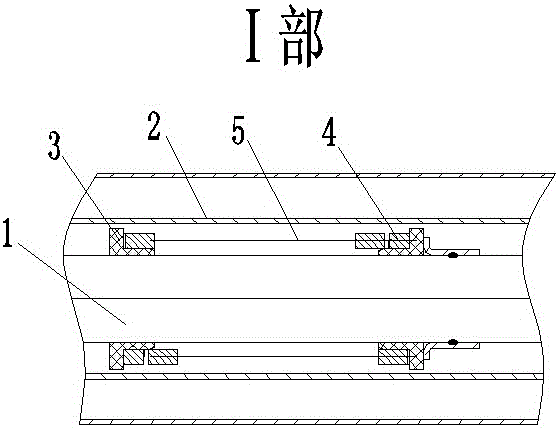

[0019] The present invention is arranged on the piston rod 1, between the piston rod 1 and the working cylinder 2, and includes sliding shoes 3 arranged at both ends of the piston rod 1, a spring 4 is arranged between the two sliding shoes 3, and one of the sliding shoes 3 is fixed Arranged on the piston rod 1 , another sliding shoe 3 can move along the piston rod 1 .

[0020] A guide sleeve 5 is sleeved on the outer side of the spring 4 .

[0021] The guide sleeve 5 includes a guide sleeve 1 51 and a guide sleeve 2 52 , wherein the guide sleeve 1 51 and the guide sleeve 2 52 are respectively fixed to the sliding shoes 3 on both sides.

[0022] The guide sleeves 5 of the present invention are arranged at both ends of the sliding shoe 3, because as long as the two ends of the spring 4 are restricted, the spring 4 will be effectively guided during the movement process, ensuring that the spring 4 can move smoothly and straightly during the movement process.

[0023] The sliding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com