Rotary oil cylinder capable of preventing travel regulation rod from falling

A technology of stroke adjustment and rotating oil cylinder, applied in the direction of fluid pressure actuating device, etc., can solve the problems of oil leakage, human and object injury, failure and other problems of rotating oil cylinder, and achieve the effect of solving safety hazards, avoiding falling off, and avoiding oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

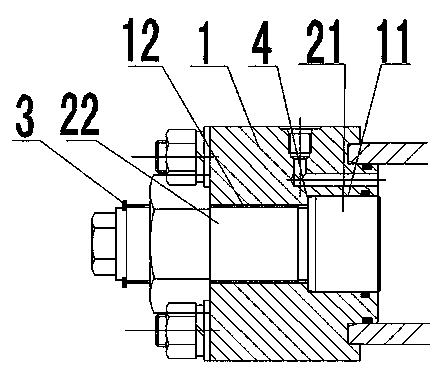

[0009] See figure 1 , It includes two limit end caps 1 and two stroke adjustment rods 2, see figure 2 Each stroke adjustment rod includes a polished rod 21 and a screw 22, and each limit end cover includes a light hole 11 and a threaded hole 12. The diameter of the polished rod on each stroke adjustment rod is larger than the diameter of the screw, and the polished rod and the light hole form a stop 4 structure. Due to the stop structure provided on the stroke adjusting rod, even if the thread on the stroke adjusting rod fails, the stroke adjusting rod will not fall off from the limit end cover of the oil cylinder.

[0010] In order to prevent the stroke adjusting rod from being over-twisted inward, an elastic retaining ring 3 for the shaft is added to the part of the stroke adjusting rod exposed to the outside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com