Expansion bolt

A technology of expansion screws and expansion sleeves, applied in the direction of screws, nuts, bolts, etc., which can solve the problems of complex installation of expansion screws, easy loosening, and potential safety hazards of screws

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

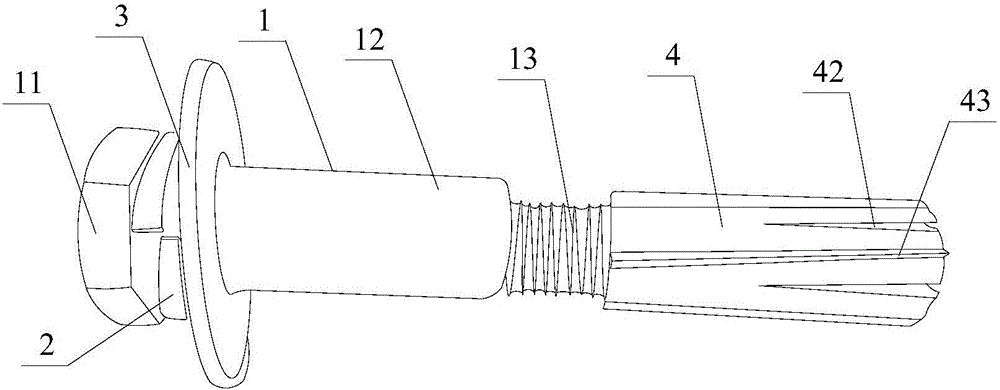

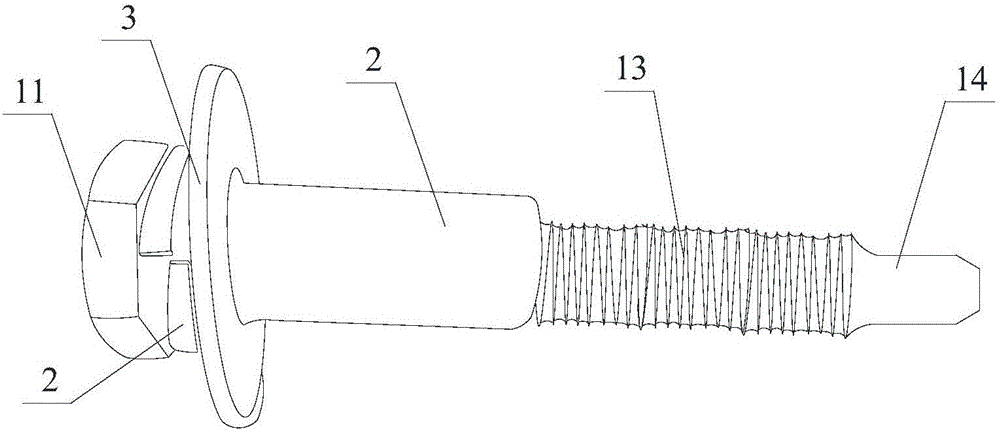

[0034] During the installation process, insert the expansion screw into the installation hole, clamp the head of the expansion screw with a wrench or a special screw tool, and screw it tightly. The wedge-shaped head of the screw continues to push up into the expansion sleeve, and the cover of the expansion sleeve Extruded, and due to the existence of the expansion gap, the expansion sleeve expands outward along the through hole. At this time, the strip-shaped ribs on the outer surface of the expansion sleeve will be more squeezed and clamped to the wall or object outside the installation hole. , to improve the firmness of the clamping, so that the installation and fixing of the expansion screw is reliable and does not loosen, and the screw and the hexagonal head are all inside the wall, which will not be exposed to the sun and rain, and will not be easily weathered and rusted.

[0035] During the disassembly process, if an ordinary wrench is used, use the wrench to clamp the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com