Novel assembled steel skeleton wood member

A prefabricated and wooden component technology, which is applied in the direction of building components, long-strip structural components for load-bearing, structural elements, etc., can solve the problem that the components cannot transmit tension, and avoid the out-of-plane instability and isolation of steel beams , Improve the effect of out-of-plane stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

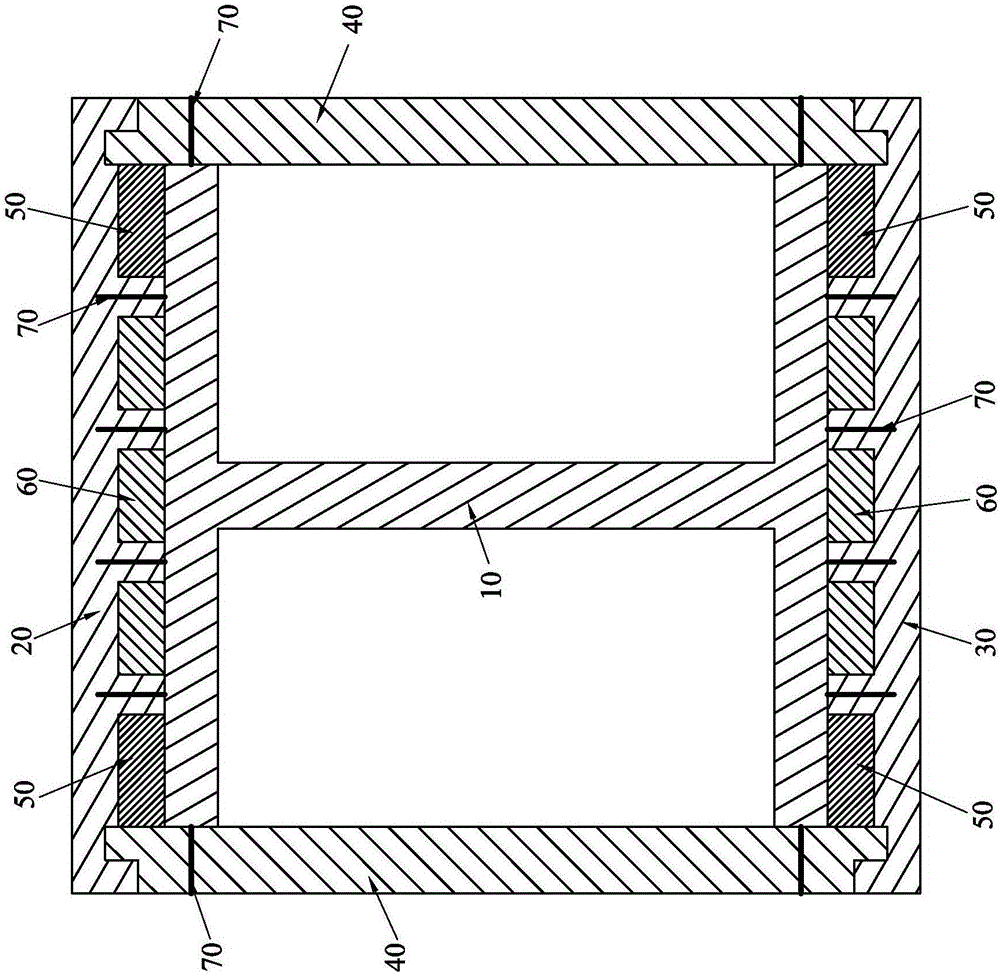

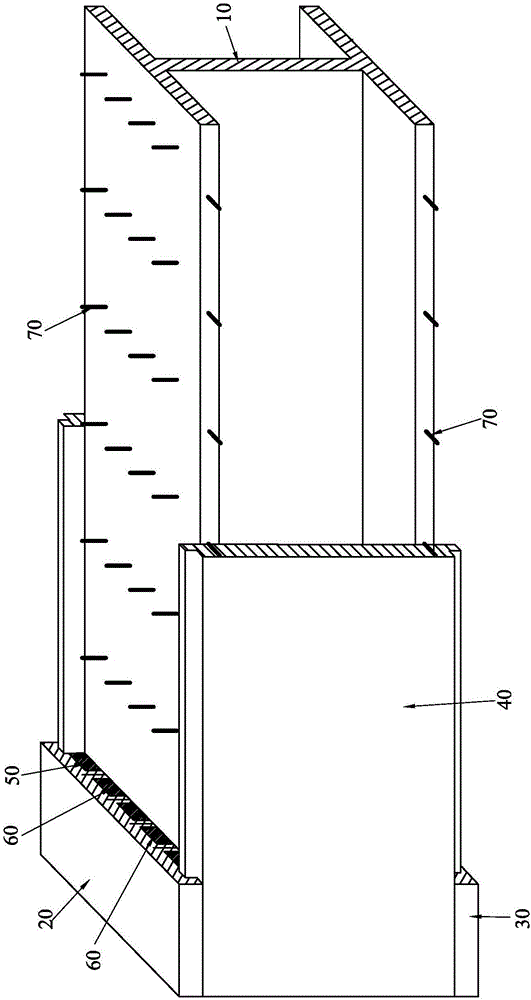

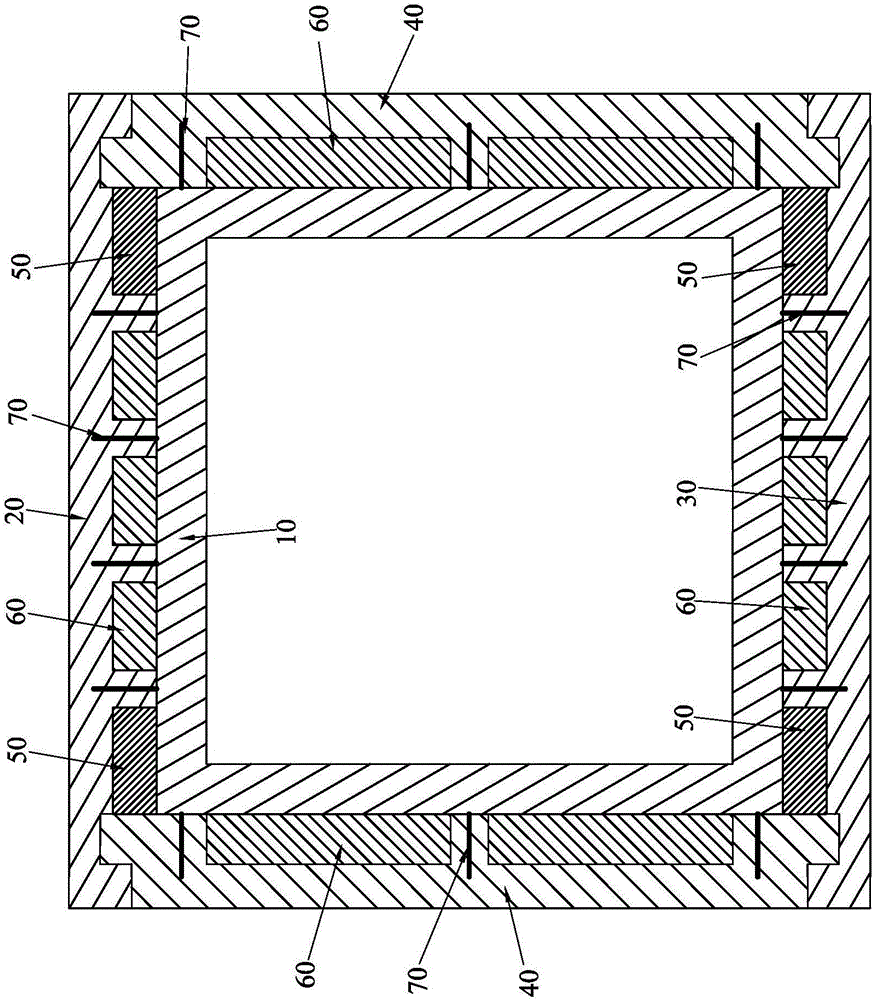

[0026] Please refer to figure 1 and figure 2 As shown, it shows the specific structure of the first preferred embodiment of the present invention, including shaped steel 10 , upper flange plank 20 , lower flange plank 30 and both side flange planks 40 .

[0027] The profiled steel 10 is a wide-flange H-shaped structure; the upper flange plank 20 and the lower flange plank 30 cover the upper and lower flange surfaces of the profiled steel 10 respectively, and the upper and lower flange planks 20 and the lower flange The planks 30 are all fixedly connected to the profiled steel 10, the upper flange plank 20 and the upper flange surface of the profiled steel 10 and the lower flanged plank 30 and the lower flanged surface of the profiled steel 10 are provided with sound-absorbing materials 50 and thermal insulation materials 60.

[0028] The two side flange planks 40 are respectively arranged on the both side flanges of the profiled steel 10 and are fixedly connected with the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com