Railway nonstandard beam erection construction method

A technology for standard beams and railways, applied in bridge construction, erection/assembly of bridges, bridges, etc., can solve the problems of high cost of foundation treatment of strip foundations or pile foundations, and large amount of steel, achieving high erection efficiency and saving production costs. , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below with reference to the drawings and an embodiment.

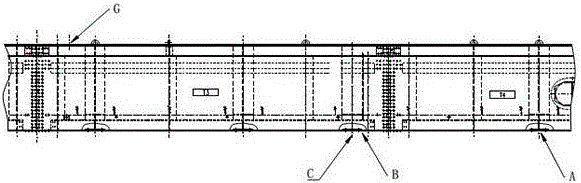

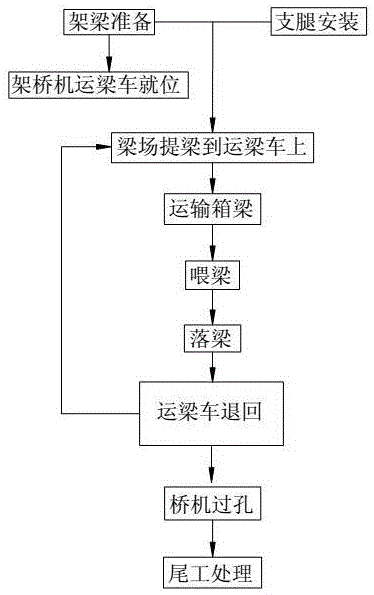

[0036] Such as figure 1 with figure 2 As shown, in the process of installing the lower guide beam support in the present invention, according to the different hole spans of the non-standard beam, the installation position of the front support leg should be recalculated at the front end of the lower guide beam, and the front support leg should be installed; Re-drill holes on the bottom plate of the lower guide beam, and weld the supporting stiffener plate inside the guide beam box.

[0037] A new construction bid section in front of a railway passenger dedicated line with a total length of 40.308 kilometers and a total of 1074 hole box girder erected. Among them, in order not to encroach on small rivers, ditches, and cross-country roads, 3-hole non-standard box girder is used for hole span adjustment.

[0038]

[0039] This construction method realizes the erect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com