A composite pressure screen

A technology of pressure screen and sieve plate, which is applied in textiles and papermaking, papermaking, fiber raw material processing, etc., can solve the problems of high content of large particles of impurities, reduce the service life of equipment, increase the wear and tear of pulping equipment, etc., and achieve the goal of impurity water content Low, reduce installed power, improve the effect of site utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

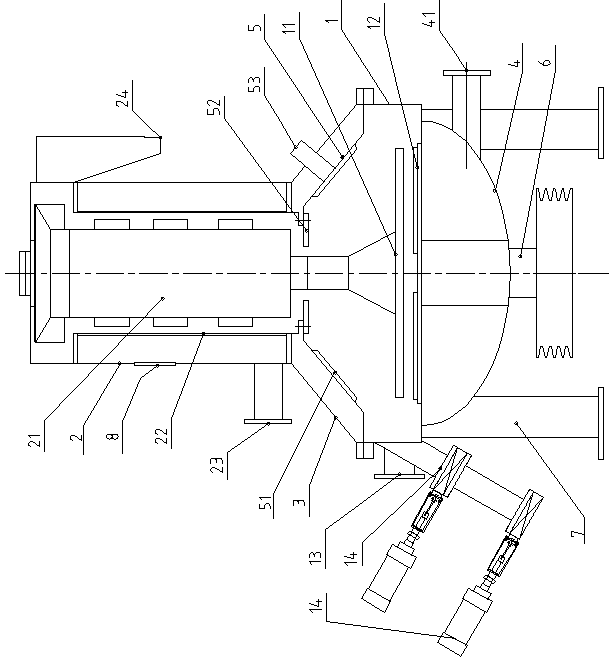

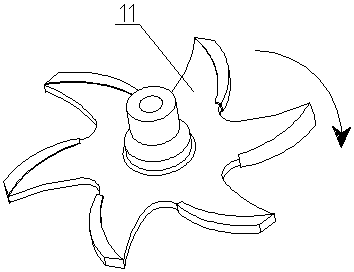

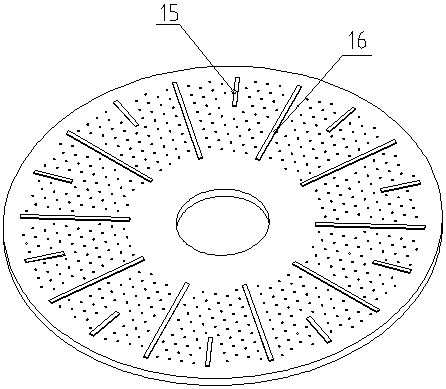

[0038] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing, figure 2 The arrows in indicate the direction of rotation of the plate rotor, Figure 4 Arrows in indicate the direction of rotation of the cylindrical rotor.

[0039] Such as Figure 1 to Figure 6Shown, a kind of composite pressure screen of the present invention, it comprises pressure screen housing and the screening structure that places in pressure screen housing, and described pressure is a kind of composite pressure screen, and it comprises pressure screen housing and places in pressure screen housing The screening structure in the body, the pressure screen housing includes the first-level screening housing 1, the transition housing 3 and the second-level screening housing 2 arranged in sequence from bottom to top, the first-level screening housing 1, the transition housing 3 and the second-level screening housing The screening housing 2 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com