Softening-free concentration device for desulfurization wastewater from power plant

The technology of desulfurization wastewater and concentration device is applied in the field of water treatment, which can solve the problems of high concentration cost and high softening cost, and achieve the effects of convenient operation, low energy consumption and simple equipment structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

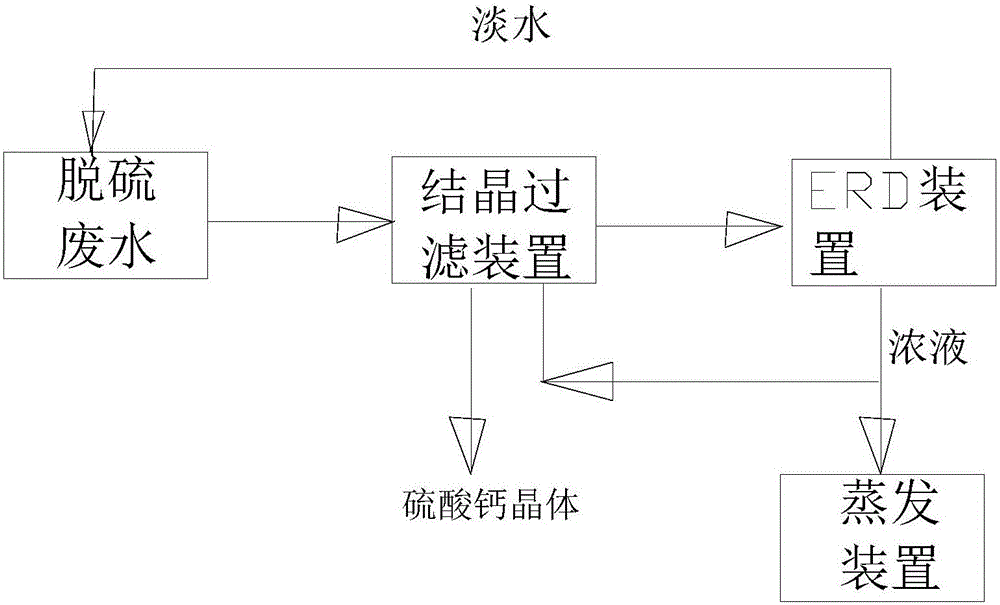

[0023] as attached figure 1 As shown in the structure, there is no need to soften and concentrate the desulfurization wastewater of a power plant, which includes a crystallization filter device, a high-frequency magnetic field generator, and an EDR device; Calcium crystals are discharged, and the water outlet of the crystallization filter device is connected to the inlet of the EDR device, wherein the crystallization filter device fixes calcium sulfate crystal seeds with a diameter of 1-100 microns on the stainless steel multi-layer grid plate in the device, The filter membrane wherein is a tetrafluoroethylene hollow fiber membrane; the high-frequency magnetic field generator utilizes a high-frequency oscillator to generate a high-frequency magnetic field with a frequency of 50KHz-50MHz; the dope outlet of the EDR device is divided into two , which are respectively connected to the crystallization filter device and the evaporation device, and the fresh water outlet is connecte...

Embodiment 2

[0027] according to figure 1 As shown in the principle structure, the power plant desulfurization wastewater with an assembly capacity of 1 ton per hour does not need a softening and concentrating device, including a crystallization filter device, a high-frequency magnetic field generator, and an EDR device.

[0028] Crystallization filter device, in which calcium sulfate seeds with a diameter of 15 microns are fixed on a stainless steel multi-layer grid plate with a density of 10 per square centimeter. The multi-layer grid plate can rotate around the center at a speed of 1 minute 10 turns. The filter is a tetrafluoroethylene hollow fiber membrane with a membrane diameter of 1.2 mm and a membrane pore size of 0.5 micron. Place the EDR membrane assembly in a high-frequency magnetic field with a frequency of 300KHz. Frequent pole reversal homogeneous membrane electrodialysis device, pole reversal frequency is 4 times per hour.

[0029] A stream of desulfurization waste liquid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Membrane pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com