A tape dismantling vehicle

A tape and frame technology, applied in the field of belt conveyor belt disassembly and assembly devices, can solve the problems of inability to realize fast retraction and fast moving of fixed belt conveyor belts, and achieve the effect of fast shortening of moving, small size of parts, and fast moving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

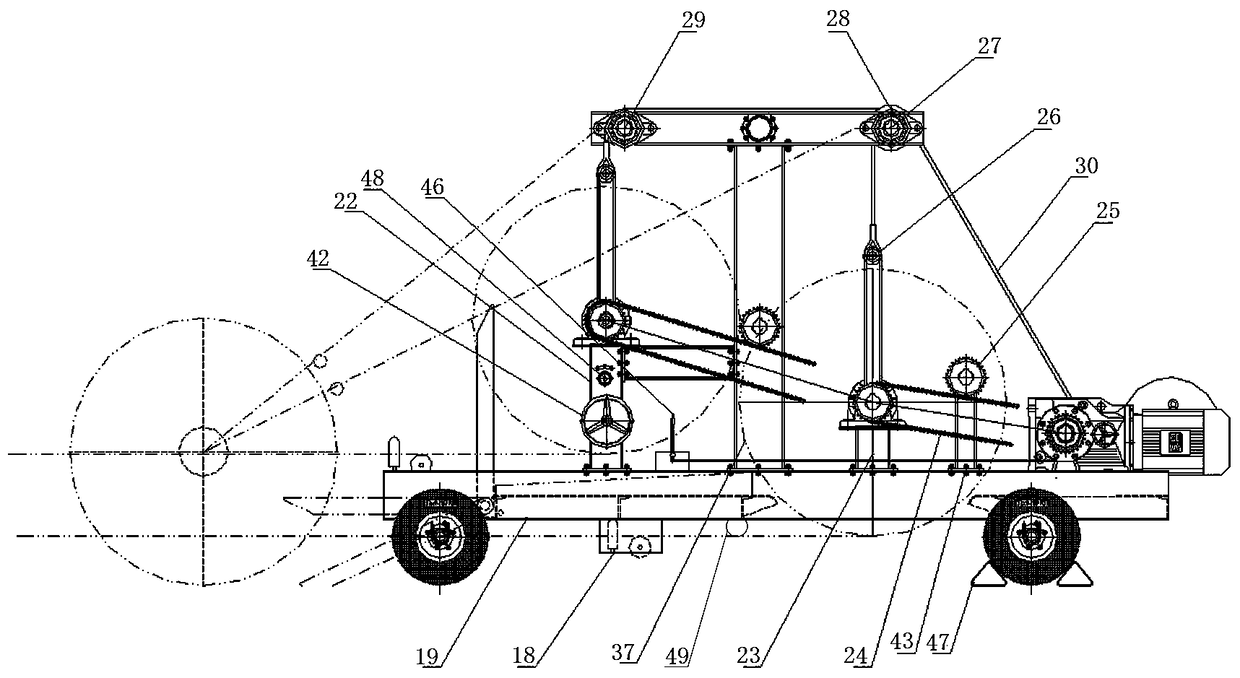

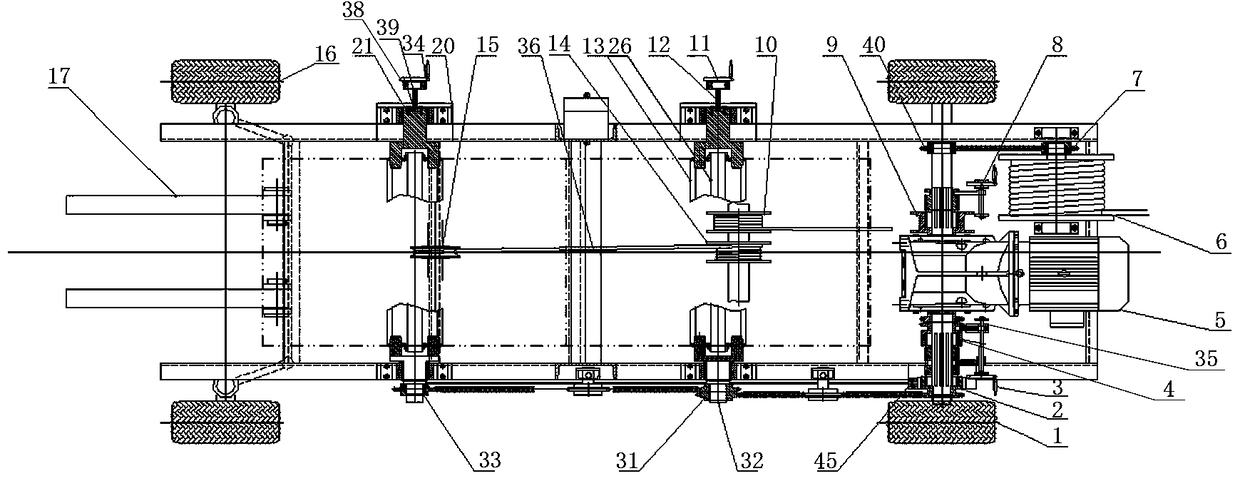

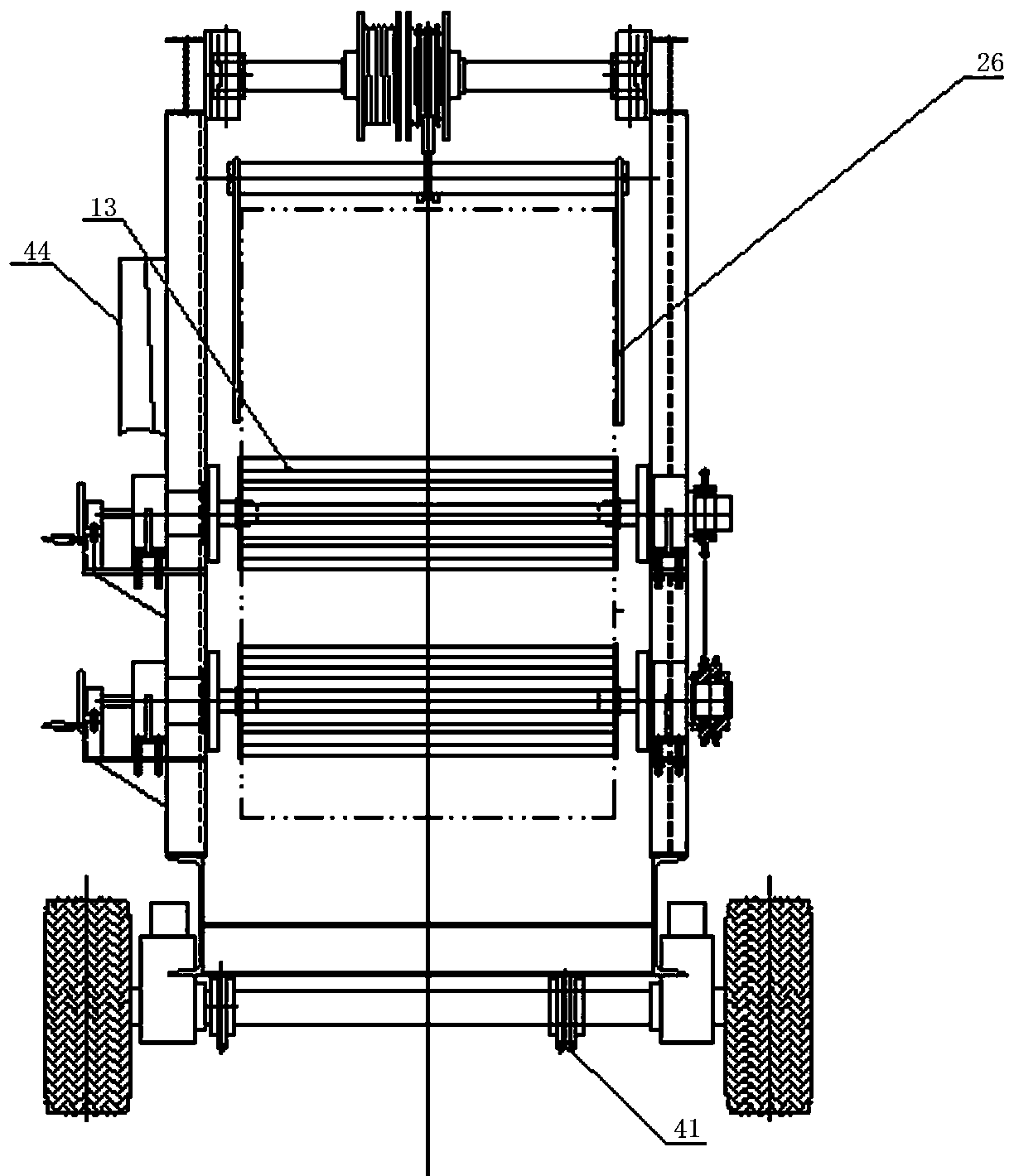

[0031] Such as figure 1 , 2 , shown in 3, a kind of adhesive tape dismantling car, comprises vehicle frame 19, is installed in the driving axle 1 below vehicle frame 19 rear ends, is installed in the steering axle 16 below vehicle frame 19 front ends, is hinged on vehicle frame 19 front ends Drop frame 17, bracket A22, bracket C37, bracket B23 and bracket D43, steel wire rope A30 and steel wire rope B36 fixedly installed in the center of vehicle frame 19 at intervals in turn, drive axle 1 refers to tricycle sprocket drive axle, and steering wheel shaft 16 refers to truck steering mechanism and axle , Landing gear 17 draws lessons from the flatbed truck landing gear principle, and its one end is hingedly installed in the middle of vehicle frame 19 front beams, and stage clip is installed in landing gear 17, can be controlled as three working states after installation: one, downward rotation, The other end of the undercarriage 17 is pressed against the ground, and becomes the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com