Electronic brake booster

An electronic brake and booster technology, which is applied in the direction of brakes, brake transmission devices, vehicle components, etc., can solve the problems of complex structure, hard work of the brake pedal, and small bearing capacity of the ball screw, so as to reduce costs, The effect of increased transmission torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

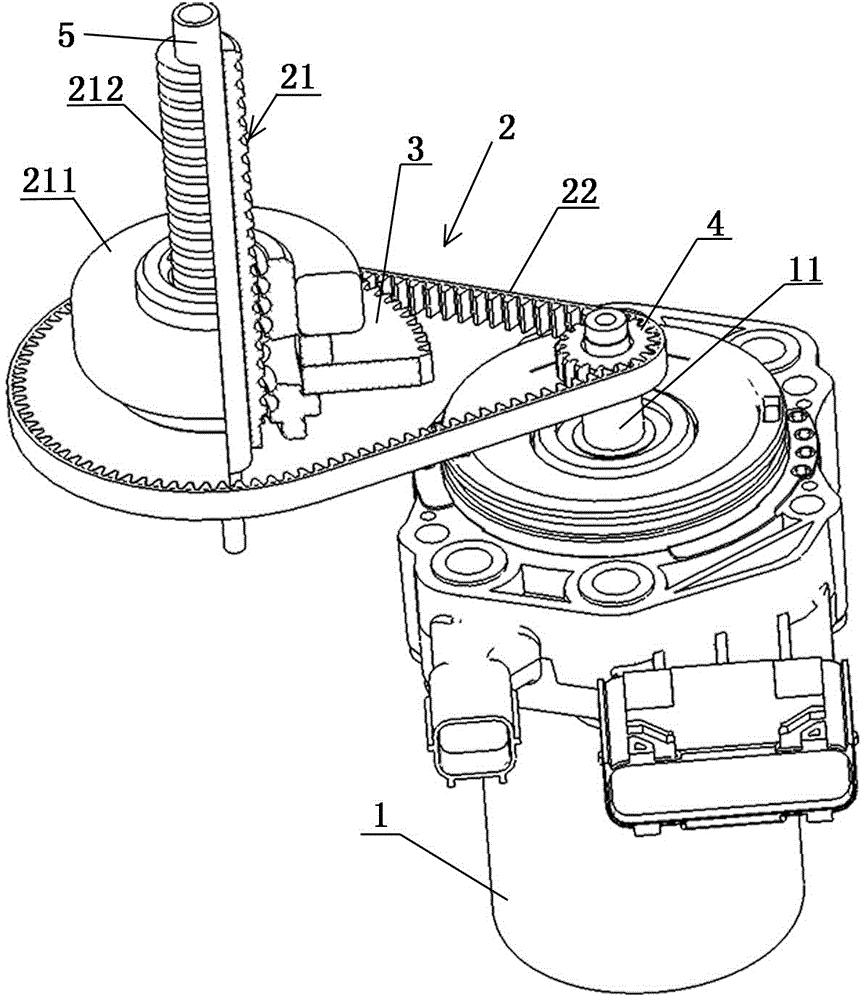

[0010] Referring to the accompanying drawings, the electronic brake booster includes a motor 1 and a booster transmission device, the booster transmission device is driven by the motor and has a rotation / translation conversion transmission mechanism 2, and the conversion transmission mechanism 2 drives the rotation of the motor 1 The output motion converted into translation for manipulating the braking system, the conversion transmission mechanism 2 includes a threaded screw 21 and a toothed transmission belt 22, the threaded screw 21 includes a nut 211 and a screw rod 212, the inner surface of the nut 211 An internal thread is provided, and the outer surface of the screw 212 is provided with an external thread. The nut 211 and the screw 212 are threaded, and the motor 1 is connected to the nut 211 through a toothed transmission belt 22 .

[0011] In this embodiment, the outer ring of the nut 211 is provided with a coaxially rotating nut gear 3, the motor shaft 11 of the motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com