Granulator for plastic particle production

A technology of plastic pellets and pelletizers, applied in the direction of coating, etc., can solve the problems of undiscovered patent publications, etc., and achieve the effects of saving production raw materials, simple structure, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

[0023] The structures, connections and methods not described in detail in this patent application can be understood as common knowledge in this field, for example, the connection method disclosed in the patent publication CN202517613U.

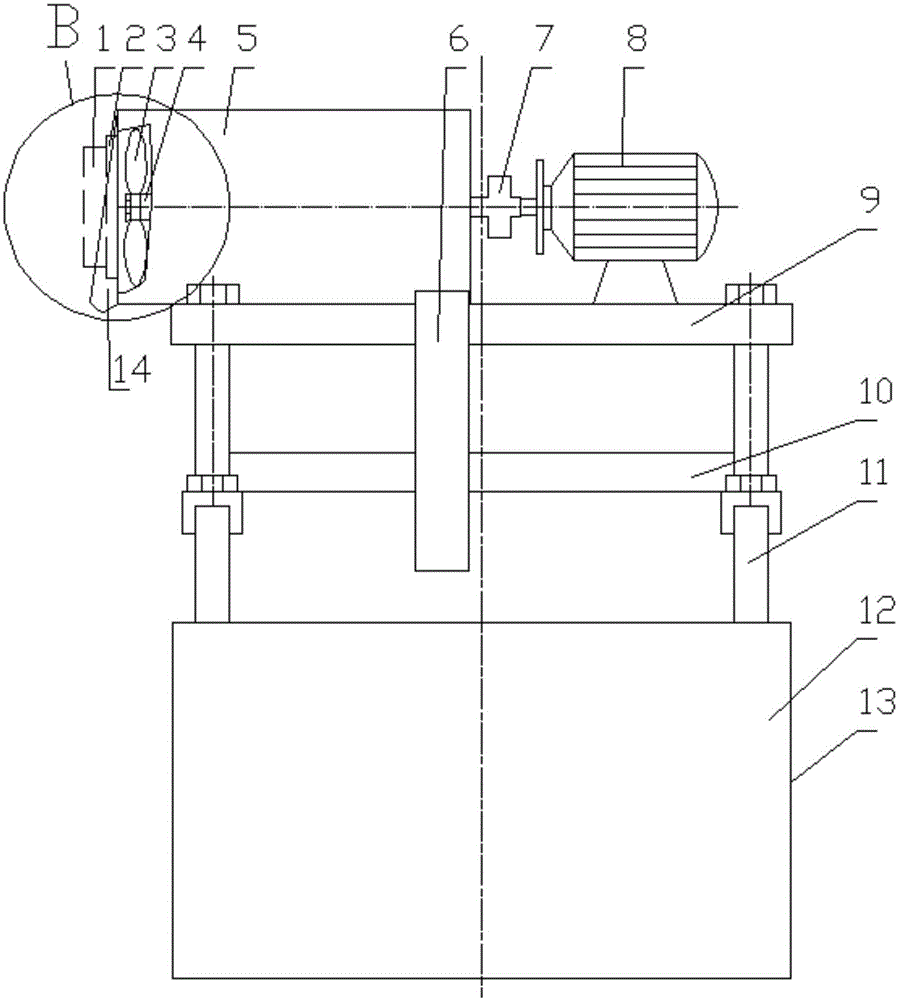

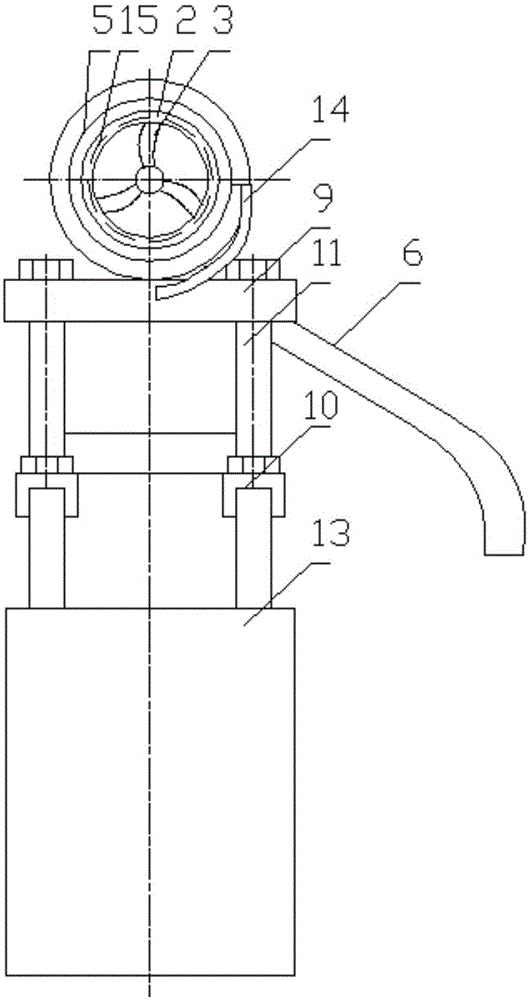

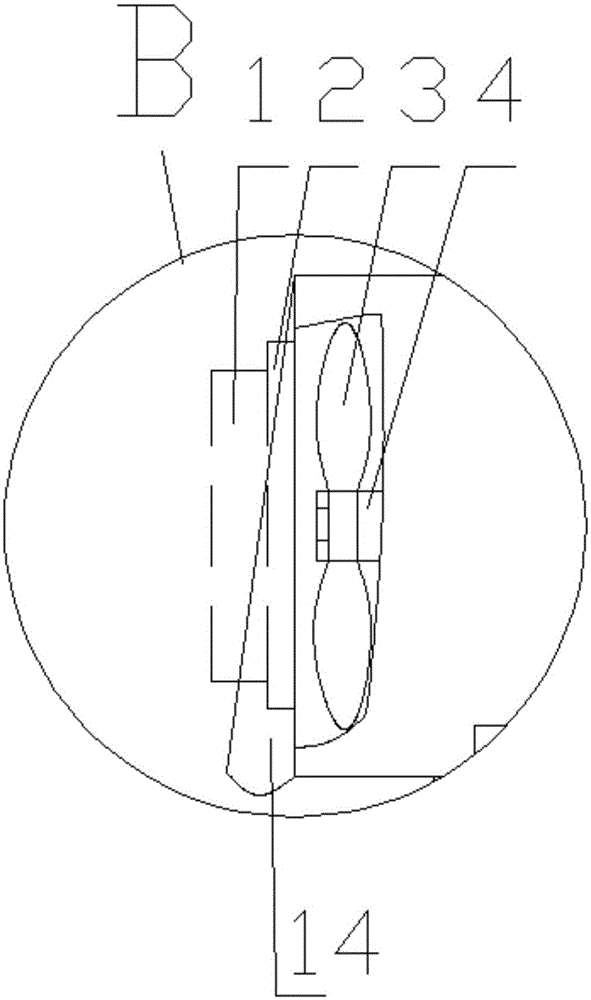

[0024] A granulator for the production of plastic granules, such as figure 1 , figure 2 and image 3 As shown, the granulator includes a frame 13, a motor 8, a pelletizing cylinder 5, a cutter 3, a sealing gasket 2 and a feed liquid outlet 6, and the motor, the pelletizing cylinder and the cutting cylinder are arranged above the frame. Knife, the granulation cylinder is a hollow cylinder with one end open, the horizontal output shaft of the motor is connected with one end of the granulation shaft 4 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com