Cap milling clamp used for crankshaft connecting rod production

A crankshaft connecting rod and cover clamping technology, which is applied in clamping, clamping devices, manufacturing tools, etc., can solve the problems of low processing efficiency, inconvenient removal of parts after clamping, and high labor intensity of workers, so as to improve processing efficiency and reduce The effect of labor intensity and convenient clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions in the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

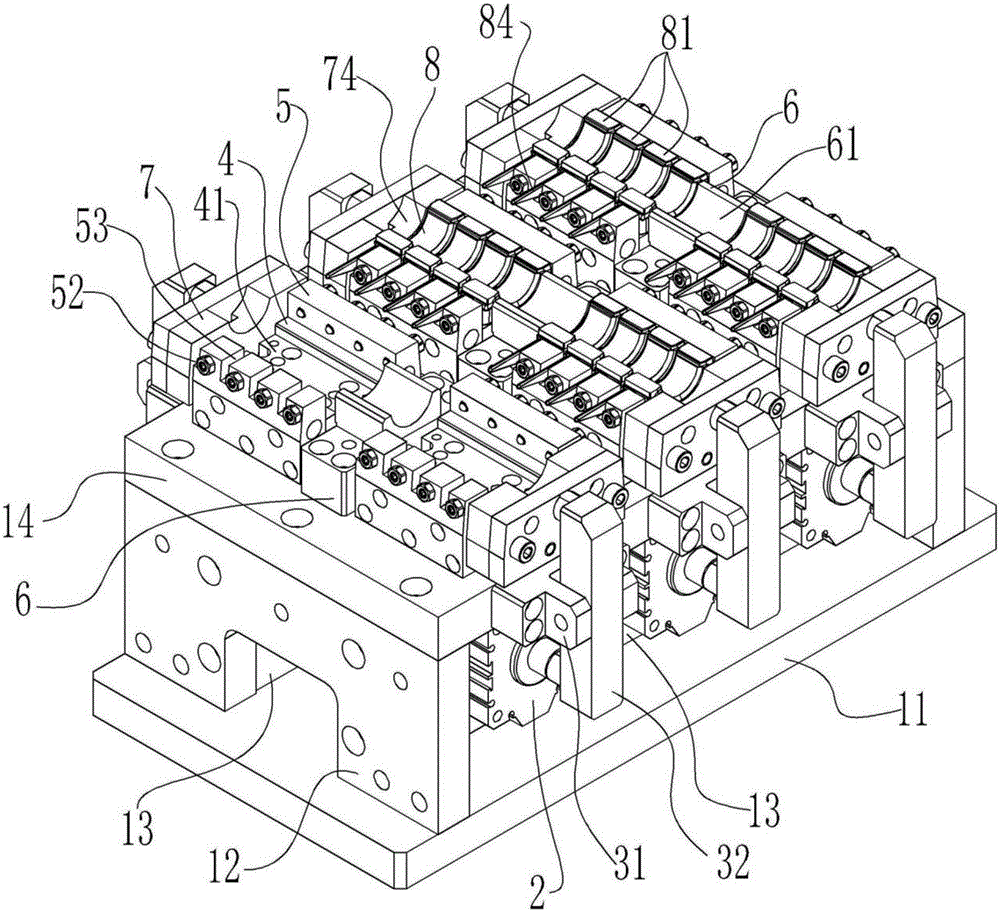

[0022] As shown in the figure, the present invention proposes a milling fixture for crankshaft connecting rod production, including:

[0023] Roughly rectangular parallelepiped mounts, such as figure 1 As shown, the mounting seat includes a horizontal bottom plate 11, two wide-side side plates 12 and two long-side side plates 13 vertically fixed on the bottom plate 11, and a top plate 14 fixed on the upper end of the wide-side side plate 12, two The wide-side side plate 12 and two long-side side plates 13 surround a cuboid structure and the long-side side plate 13 is set in a sunken type, and the top plate 14 and the long-side side plate 14 are all provided with mounting screw holes;

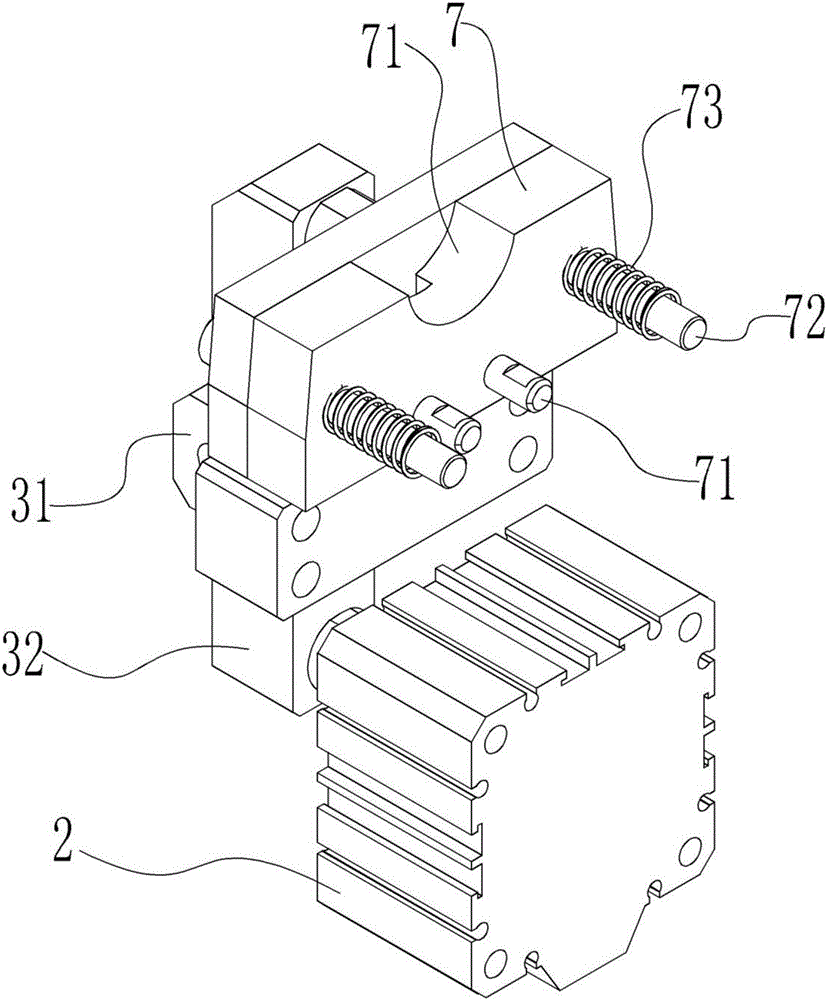

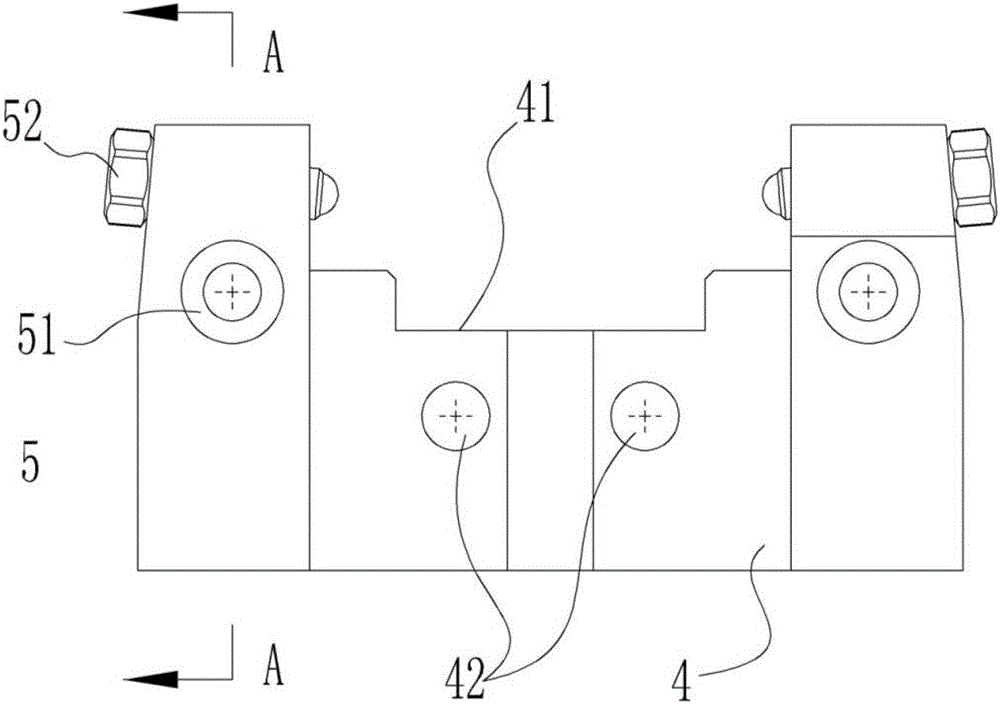

[0024] Many pairs of lever mechanisms that are symmetrically arranged on the two opposite side walls of the top plate 14 and the cylinders 2 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com