Stirring scraper of ice cream machine

An ice cream machine and scraper technology, applied in frozen desserts, food science, applications, etc., can solve the problems of easy deviation, affecting the stirring scraper, scraping damage of the scraping cylinder, etc., to compensate for processing and assembly errors, and reduce the occurrence of failures The effect of ensuring the scraping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

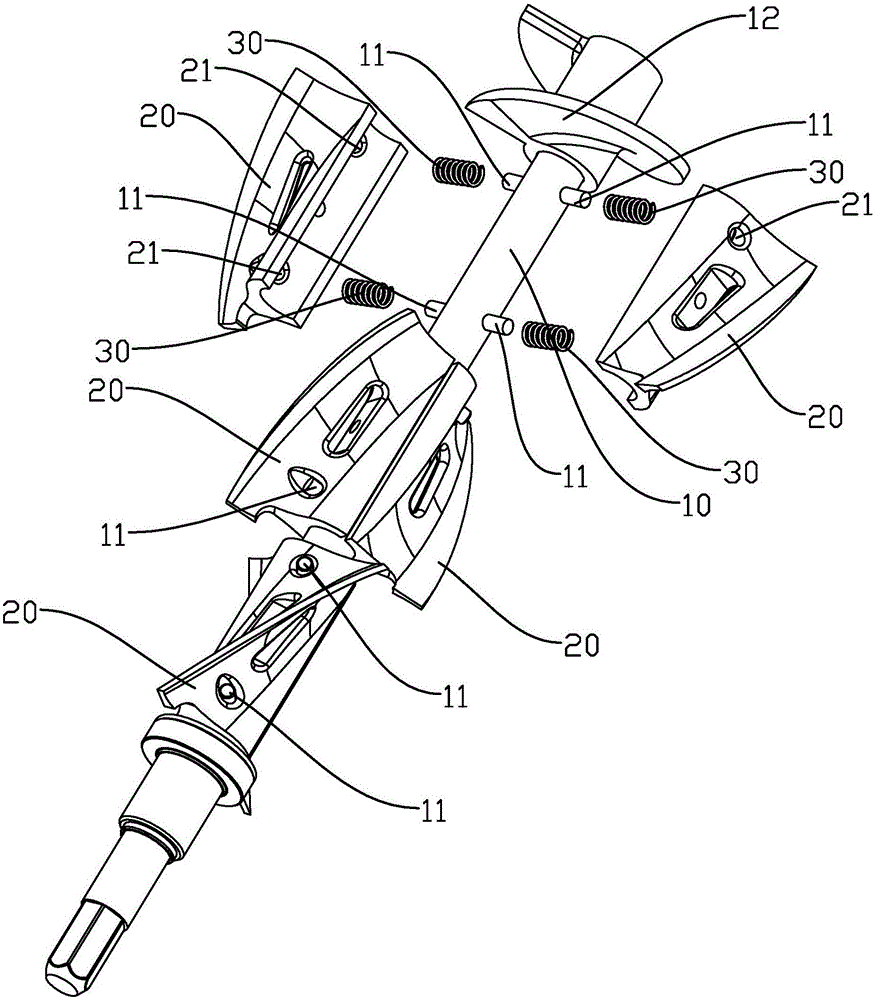

[0015] refer to figure 1 , a stirring scraper for an ice cream machine, comprising a base rod 10 and at least one scraper member 20 arranged on the base rod 10, the base rod 10 is usually connected with an external motor and other driving devices to rotate around its central axis, and the scraper member 20 The lateral sliding is arranged on the base rod 10, and an elastic member for pushing the scraper part 20 away from the base rod 10 is arranged between the scraper part 20 and the base rod 10. In the present invention, the lateral sliding of the scraper part 20 is arranged on the base rod 10, and an elastic member 30 for pushing the scraper member 20 to the base rod 10 is set between the scraper member 20 and the base rod 10, so that when the mixing scraper rotates in the scraper cylinder, the elastic member 30 can The scraper piece 20 is continuously pressed against the inner wall of the scraper cylinder to avoid omissions and ensure the scraping effect, thereby effectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com