Fuel pump assembly and method for operating a similar assembly

A fuel pump and fuel technology, applied in combustion methods, fuel heat treatment devices, fuel supply, etc., can solve the problem of reduced or at least partial or even complete delivery volume, achieve reliable and precise manipulation, and improve delivery behavior.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

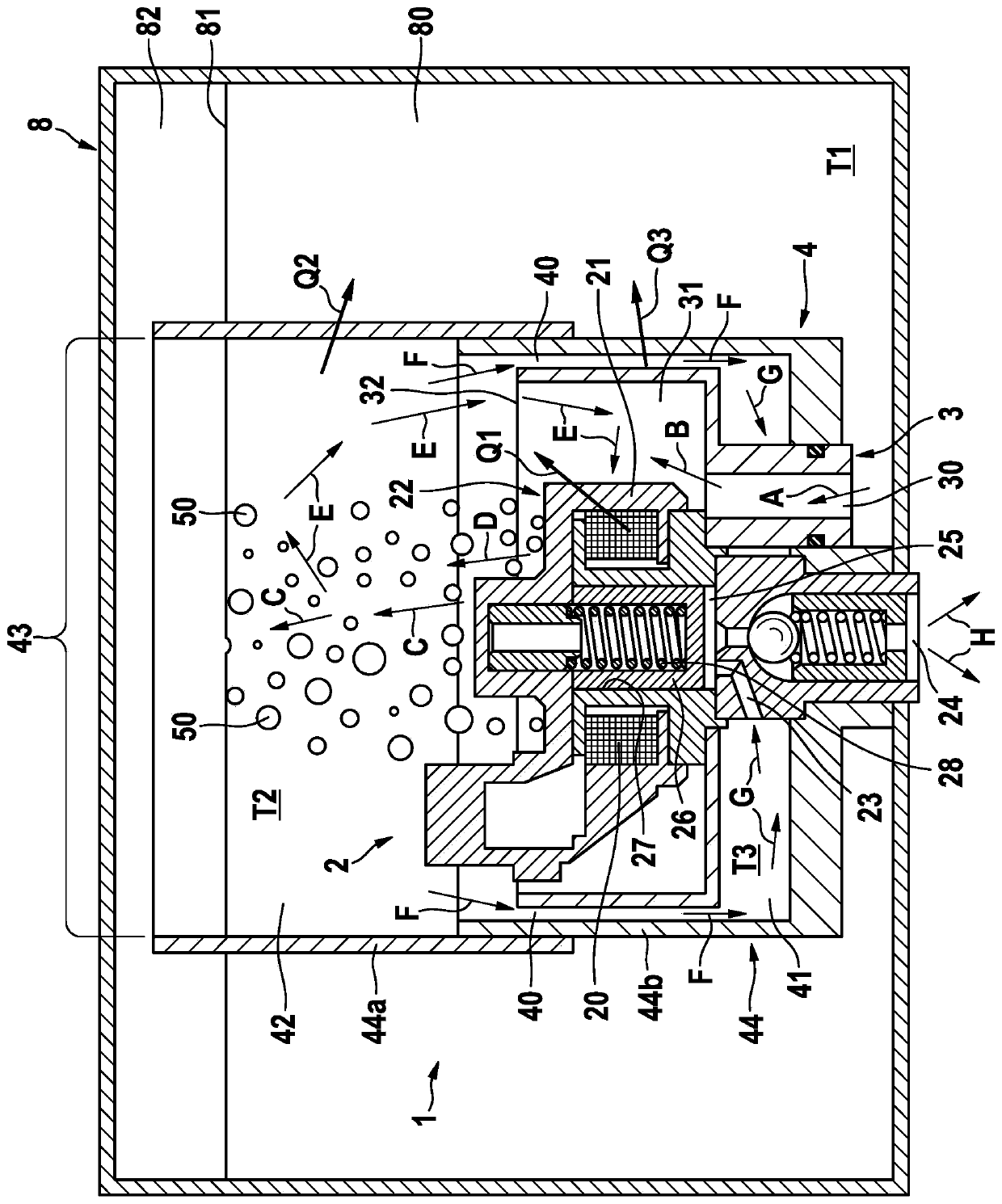

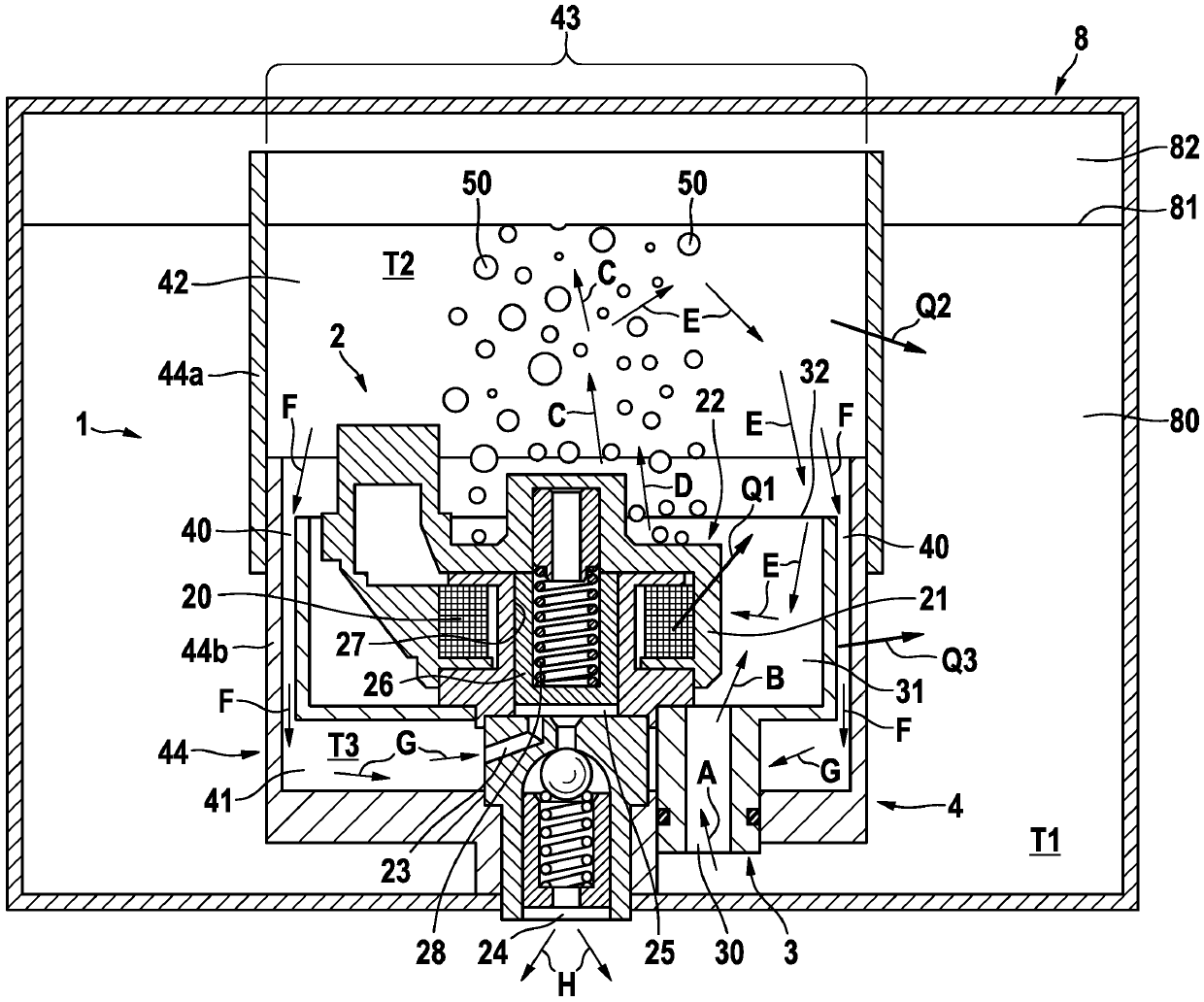

[0018] Next refer to figure 1 A fuel pump assembly 1 according to a preferred embodiment of the present invention is explained in detail.

[0019] As is evident from the single drawing, the fuel pump assembly 1 according to the invention has a fuel pump 2 , a first housing 3 and a second housing 4 . Furthermore, the fuel pump assembly 1 is arranged in a fuel tank 8 of a vehicle which is not shown. The fuel tank 8 has a fuel area 80 and an air or vapor area 82 , wherein the fuel level is indicated by a line 81 .

[0020] The fuel pump 2 as an electromagnetic piston pump has a pump housing 22 with an inlet channel 23 and an outlet channel 24 , a delivery chamber 25 , a piston 26 movable in a cylinder chamber 27 , a heat-generating actuator 20 and a spring element 28 . The fuel pump 2 is arranged such that the fuel pump 2 is arranged partly in the first housing 3 and partly in the second housing 4 . In particular, the heat-generating actuator 20 as a solenoid coil is located i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com