Gas generator

A gas generator and gas generation technology, applied in the direction of gas generating devices, chemical instruments and methods, vehicle parts, etc., can solve the problems of manufacturing cost pressure, increased number of parts, and deteriorated workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

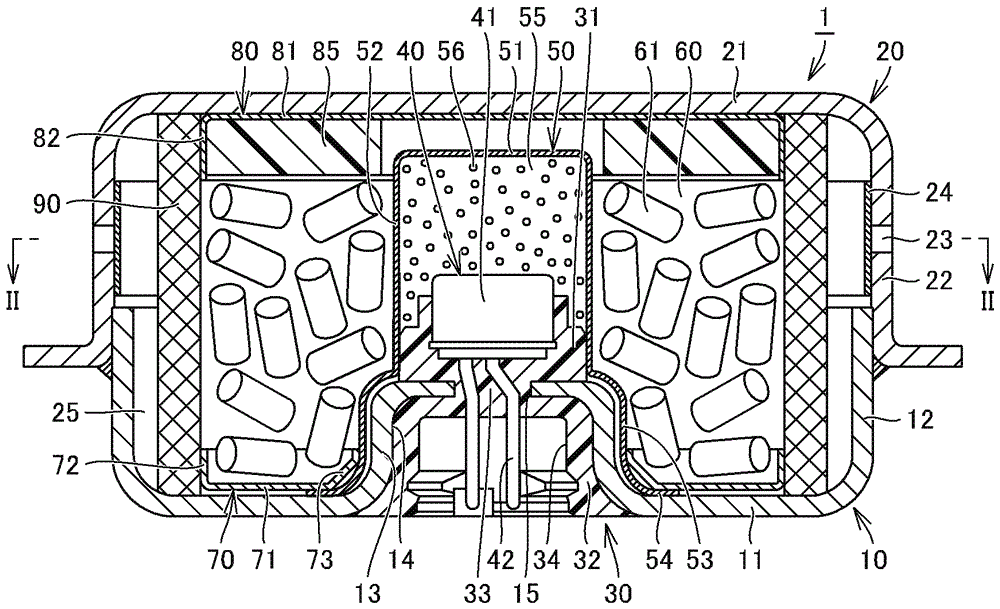

[0054] figure 1 It is a schematic diagram of the gas generator in Embodiment 1 of this invention. First, refer to the figure 1 The structure of the gas generator of this embodiment is demonstrated.

[0055] Such as figure 1 As shown, the gas generator 1 of this embodiment has a short and substantially cylindrical casing with both ends in the axial direction covered, and is configured to accommodate components as internal components in a storage space provided inside the casing. The holding part 30, the igniter 40, the cup member 50, the ignition agent 56, the gas generating agent 61, the lower support member 70, the upper support member 80, the cushion material 85, the filter 90, and the like. In addition, a combustion chamber 60 that mainly accommodates the gas generating agent 61 in the above-mentioned internal structural parts is provided in the storage space provided inside the casing.

[0056] The short-dimensioned substantially cylindrical housing includes a lower si...

no. 1 approach example )

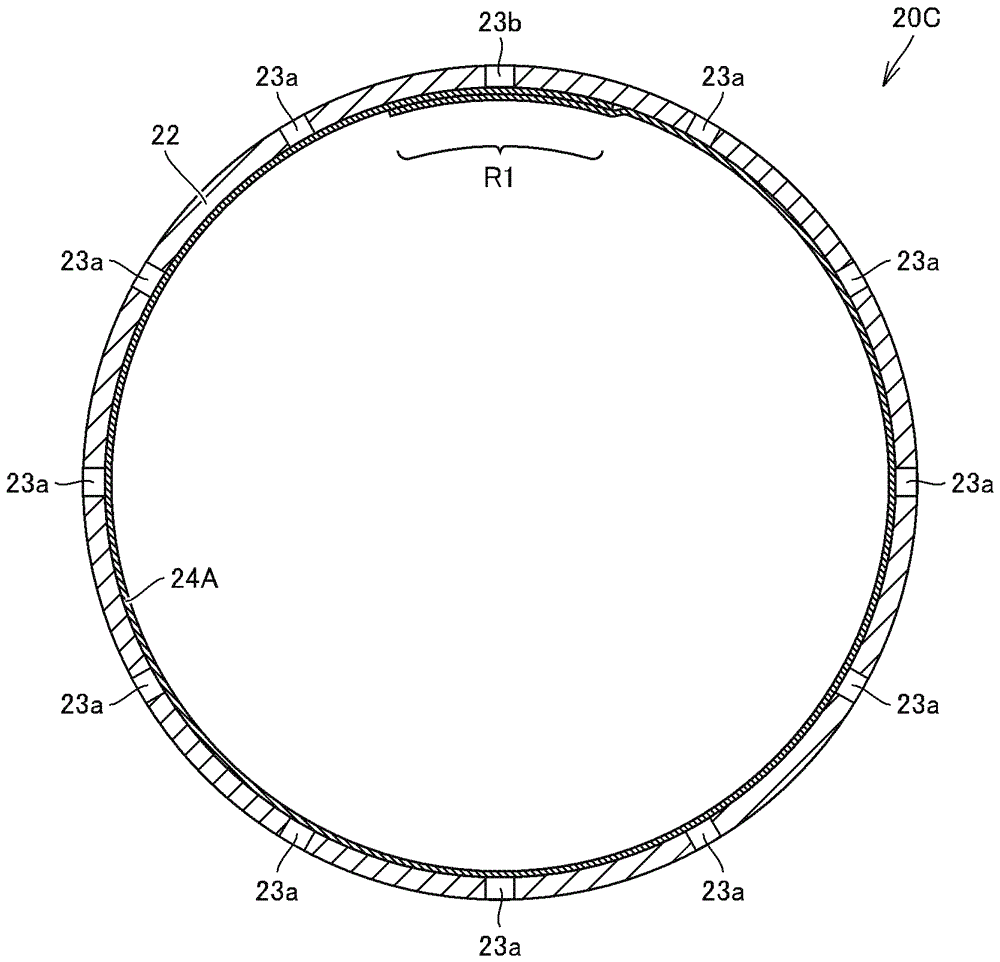

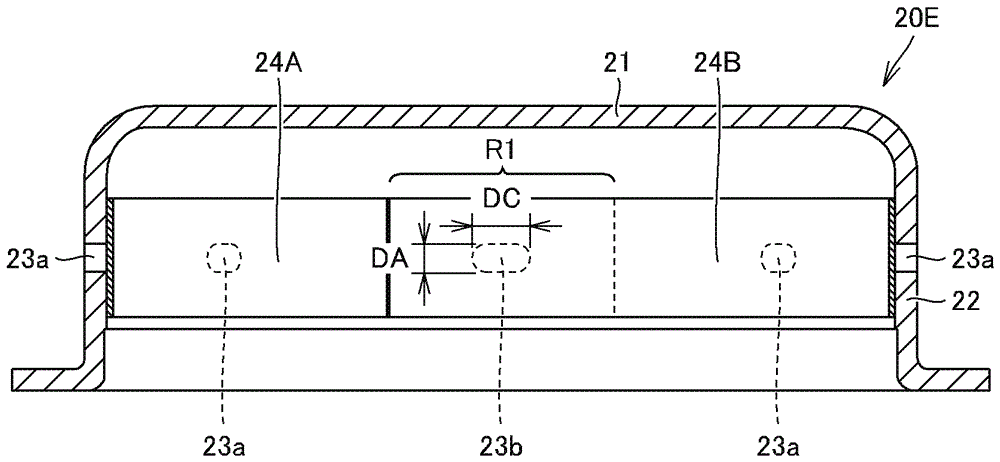

[0112] figure 2 and image 3 It is an end view and a cross-sectional view of an upper side shell related to the first example. First, refer to these figure 2 and image 3 Explain in detail the example of the first plan.

[0113] Such as figure 2 and image 3 As shown, the upper side shell 20A has a structure in which a plurality of strip-shaped sealing tapes 24A, 24B are attached to the inner peripheral surface of the peripheral wall portion 22 provided with a plurality of gas ejection ports 23a, 23b. The gas ejection ports 23a, 23b are covered with these strip-shaped multi-sheet seal tapes 24A, 24B.

[0114] The total number of gas ejection ports 23a, 23b is 12, and they are provided so as to be scattered at different positions in the circumferential direction of the peripheral wall portion 22 of the upper side shell 20A. More specifically, a total of 12 gas ejection ports 23 a , 23 b have the same opening area (that is, opening diameter) and are arranged in a row a...

no. 2 approach example )

[0121] Figure 4 It is an end view of the upper side case related to the second example. Next, refer to the Figure 4 Explain in detail the second example. In addition, when the second example is compared with the above-mentioned first example, only the structure of the overlapping region is different.

[0122] Such as Figure 4 As shown, the upper side shell 20A1 is the same as the upper side shell 20A related to the above-mentioned first embodiment, and has a structure as follows: The plurality of strip-shaped sealing tapes 24A, 24B cover the plurality of gas ejection ports 23a, 23b with these strip-shaped multi-sheet sealing tapes 24A, 24B.

[0123] Here, in the second example, unlike the above-mentioned first example, one of the pair of end portions in the extending direction of the sealing tape 24A is covered by the sealing tape 24B, and the other end portion is to be sealed. One of the pair of ends in the extending direction of the seal tape 24B is covered with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com