A kind of pcb circuit board cooling device and chassis

A technology of PCB circuit board and heat dissipation device, which is applied in the direction of printed circuit components, cooling/ventilation/heating transformation, etc., can solve the problems of uneven heat dissipation, slow heat dissipation, slow heat dissipation, etc. Well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This embodiment is applied to a PCB circuit board.

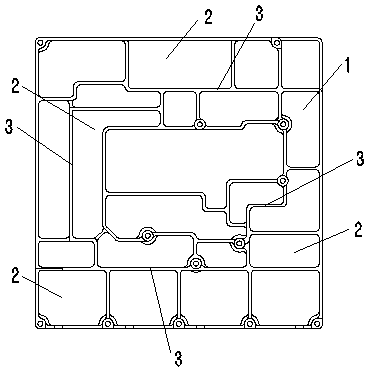

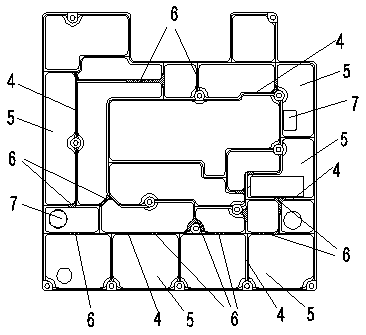

[0046] Such as Figure 1-Figure 7 As shown, the PCB circuit board heat dissipation device is used to be installed on the PCB circuit board 1, and includes a heat conduction part for contacting the heat conduction layer 3 on the PCB circuit board 1, and the heat conduction part is away from the heat conduction layer 3 One side of the heat conduction layer 3 extends, and the extended end of the heat conduction portion is connected with a heat dissipation portion.

[0047] In the prior art, the heat dissipation method of the PCB circuit board mainly adopts the natural heat dissipation method. During the use process, the PCB circuit board is installed in the chassis, and the purpose of heat dissipation is achieved through heat exchange with the air, but this natural heat dissipation The method has the characteristics of slow heat dissipation and uneven heat dissipation, which leads to an increase in the heat of the circu...

Embodiment 2

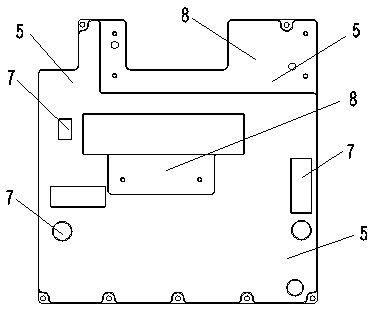

[0064] This embodiment is used for the occasion of installing a circuit board in a case.

[0065] PCB circuit board case, the PCB circuit board heat dissipation device as introduced in embodiment 1 is installed in this PCB circuit board case, during use, described PCB circuit board heat dissipation device is installed on the PCB circuit board, and heat conduction with the PCB circuit board layer contact.

[0066] Adopt above-mentioned method, arrange PCB circuit board cooling device in the case of PCB circuit board, change the structure of traditional PCB circuit board case, make the temperature of the PCB circuit board arranged in the case greatly reduce, solve the problem of PCB circuit board in the prior art. The problem of excessive temperature caused by the natural heat dissipation of the board makes the structural design of the chassis more reasonable and scientific. By arranging the heat dissipation device, the circuit board, the functional modules on the circuit board ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com