Magnesium oxide mineral-insulated cable production method

A technology of mineral insulated cables and production methods, which is applied in the direction of cable/conductor manufacturing, conductor/cable insulation, circuits, etc., which can solve the problems of large power consumption, high technical requirements, and large floor space, so as to save electric energy and shorten process, the effect of reducing the number of annealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

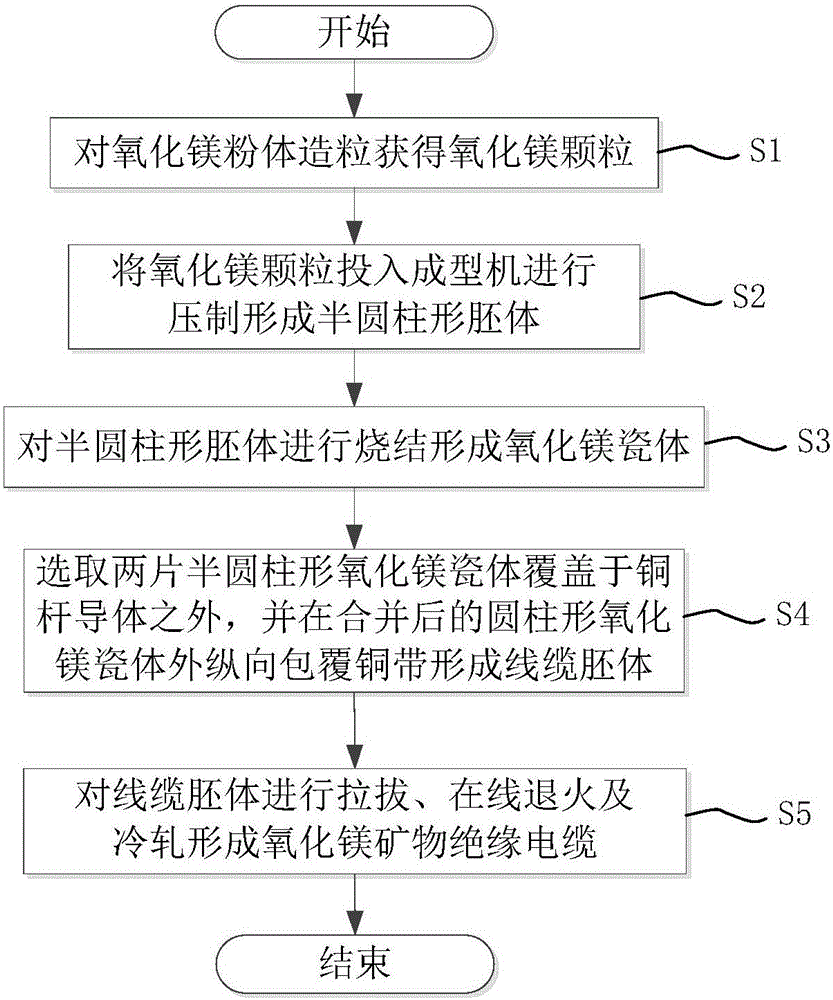

[0023] figure 1 It is a schematic diagram of the production process of the magnesium oxide mineral insulated cable of the present invention.

[0024] See figure 1 , The production method of magnesium oxide mineral insulated cables provided by the present invention includes granulation-pressing-sintering-assembly-coating-welding-drawing-on-line annealing-cold rolling-finished product inspection-warehousing.

[0025] 1. Granulation:

[0026]

[0027] Small mesh value and large particles form the skeleton of the molded body; large mesh value and small particles fill the gaps in the green body and increase the density.

[0028] 2) Glue ratio: water: polyvinyl alcohol = 100:2

[0029] The water is heated to 80-90°C, polyvinyl alcohol is incorporated, and kept at about 100°C for 2 hours, and then cooled naturally.

[0030] Polyvinyl alcohol is non-tox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com