Multichannel control device used for hydraulic vibration test system

A test system and control device technology, which is applied in the direction of electric fluid pressure control, etc., can solve the problems such as the description of the multi-dimensional hydraulic vibration table control device, and achieve the effects of eliminating resonance peaks, widening the system frequency band, and improving the automation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

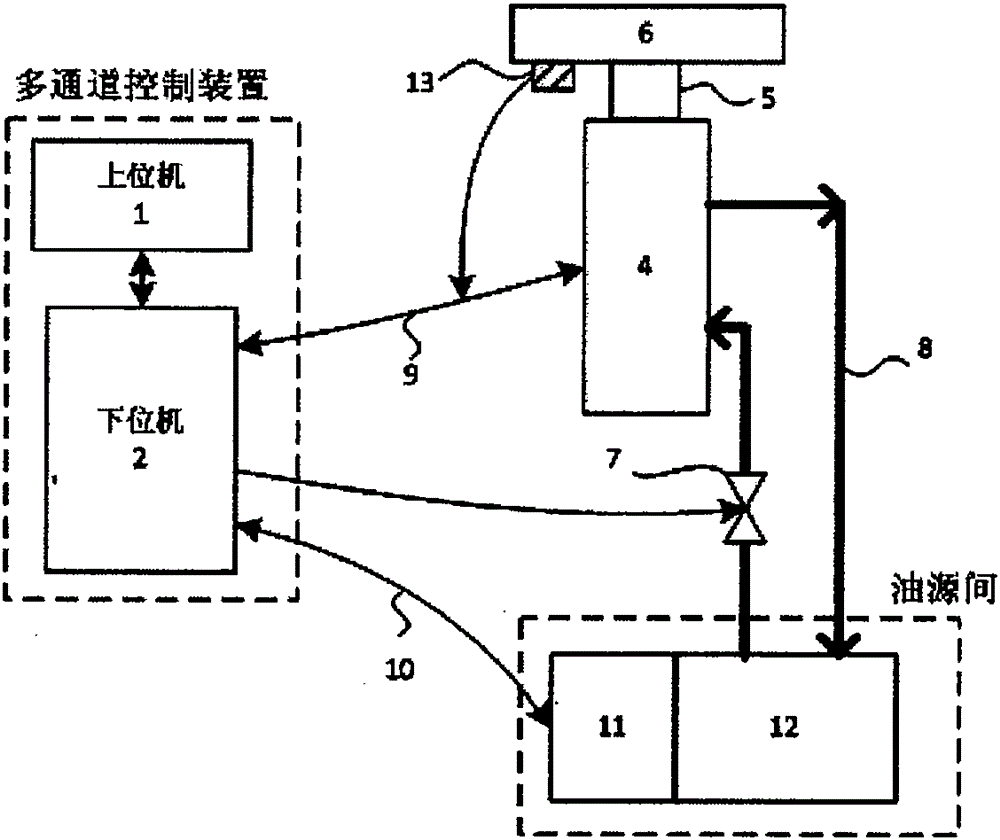

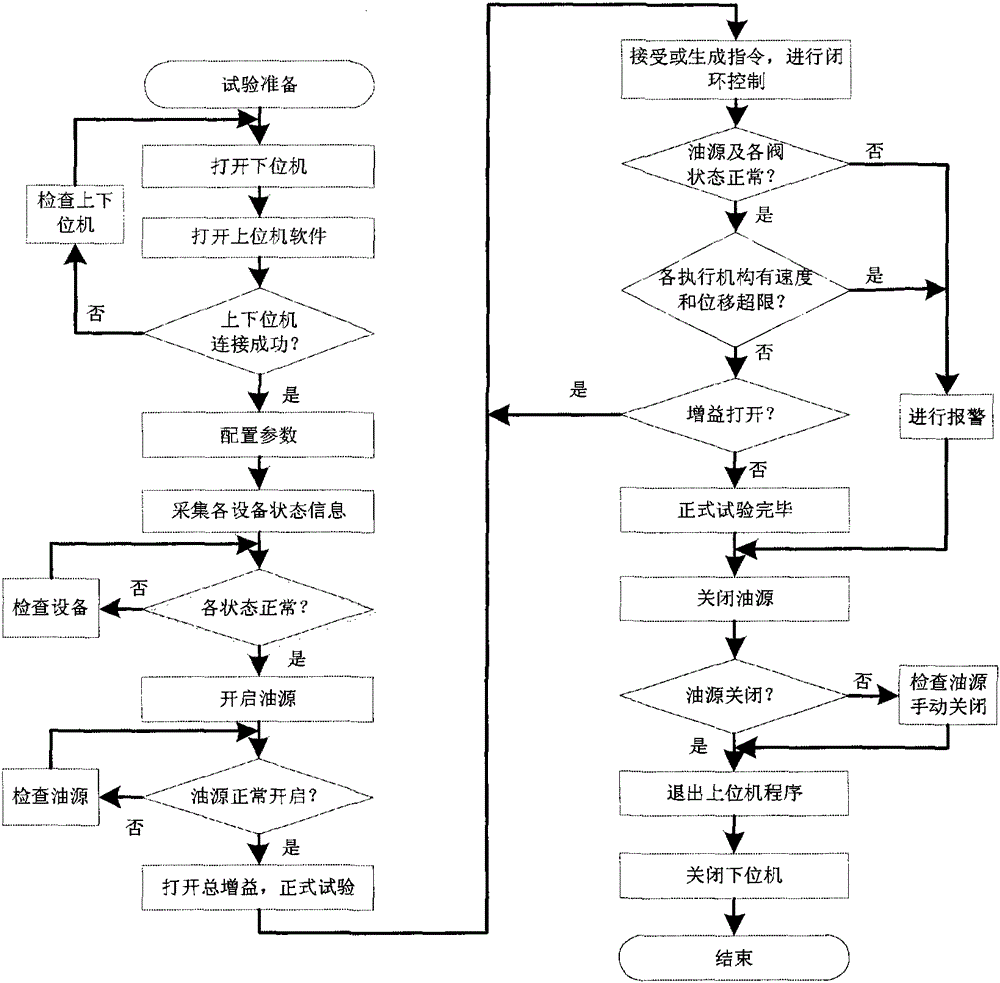

[0046] Specific examples are as image 3 As shown, the device is used in a six-degree-of-freedom hydraulic test system. The test system is scattered geographically, and the equipment is distributed in the measurement and control room, the oil source room and the experiment hall. Among them, the upper computer 1, the lower computer 2 and the vibration controller 3 with multi-channel control devices in the measurement and control room, where the test operators control the entire system; the oil source room has an oil source 12 and its electric control cabinet 11, which are used for hydraulic actuators. Provide power; the test hall has a pipeline 8 and its switch valve 7, hydraulic actuator 4, table body 6 and its connection device 5 with each hydraulic actuator 4, such as hinge connection device, signal cable 9 and twisted pair Cable 10 and other accessories, six hydraulic actuators 4 form a six-degree-of-freedom hydraulic vibration table in a 321 structure. The six signal con...

specific Embodiment 2

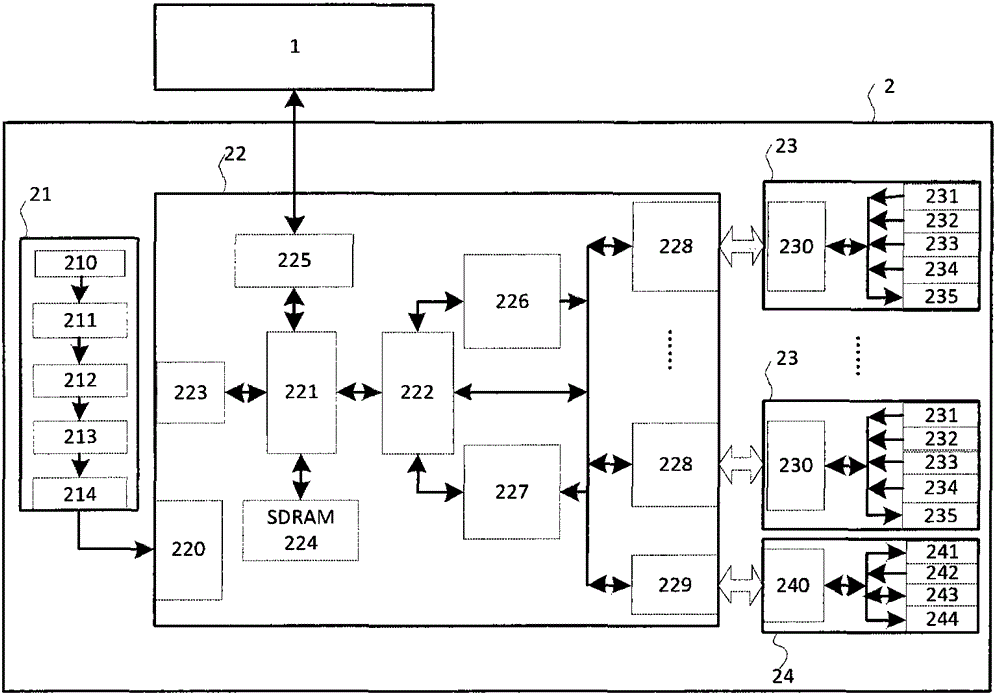

[0047] Specific embodiment two such as Figure 5 As shown, the device is used in a single-channel hydraulic test system. The test system includes an upper computer 1 and a lower computer 2 of a multi-channel control device. Similarly, the oil source 12 and its electric control cabinet 11 are located between the oil sources; the test hall has a pipeline 8 and its switch valve 7, a hydraulic actuator 4, a table body 6 and a connecting device 5 between it and the hydraulic actuator 4, Such as hydraulic ball joint connection device, acceleration sensor 13, signal cable 9, twisted pair cable 10 and other accessories, a hydraulic actuator 4 constitutes a single-channel hydraulic vibration table. A signal conditioning board 23 on the lower computer 2 of the multi-channel control device is electrically connected to the hydraulic actuator 4 through a signal cable, specifically as Figure 6 As shown, the output drive circuit 235 of the signal conditioning board 23 outputs ±10mA curren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com