Multi-industrial-robot virtual offline co-simulation system and method

An industrial robot and co-simulation technology, which is applied in control/regulation systems, instruments, motor vehicles, etc., can solve the problem of virtual off-line co-simulation methods and system implementation processes that do not involve multiple robots, and do not involve the movement of multiple robot systems. Simulation and other issues to achieve the effect of improving development efficiency, lowering technical threshold, and improving enterprise production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Such as figure 1 As shown, the multi-industrial robot virtual offline collaborative simulation system includes: a multi-robot path planning module, a multi-robot cooperative motion solution module, a robot code generation module, a motion simulation interference checking module and a file saving function module.

[0029] Such as figure 2 As shown, its method comprises the following working steps:

[0030] (1) Use the 3D modeling software core to import multiple robots, positioners and 3D digital models of workpieces to build a multi-robot virtual workstation;

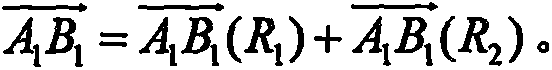

[0031] (2) Use the workpiece digital model to extract the actual machining path of the robot, use the coordinates and orientation of the machining path to determine the path of a main robot relative to the absolute coordinate system, and use this path and the actual workpiece processing path to find the paths of other robots relative to the absolute coordinate system ;

[0032] (3) Robot kinematics analysis, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com