A multi-sample automatic sample changing device for x-ray polycrystal diffractometer

An automatic sample changer and diffractometer technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of high price and complex structure of the manipulator automatic sample changer, and achieve low cost, easy promotion and use, and strong versatility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

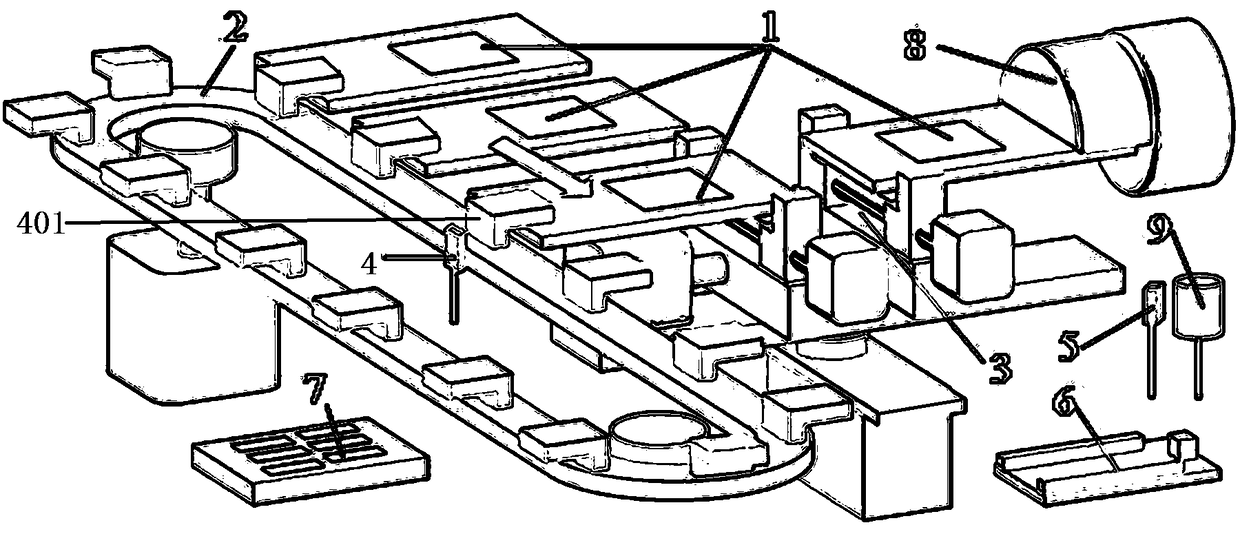

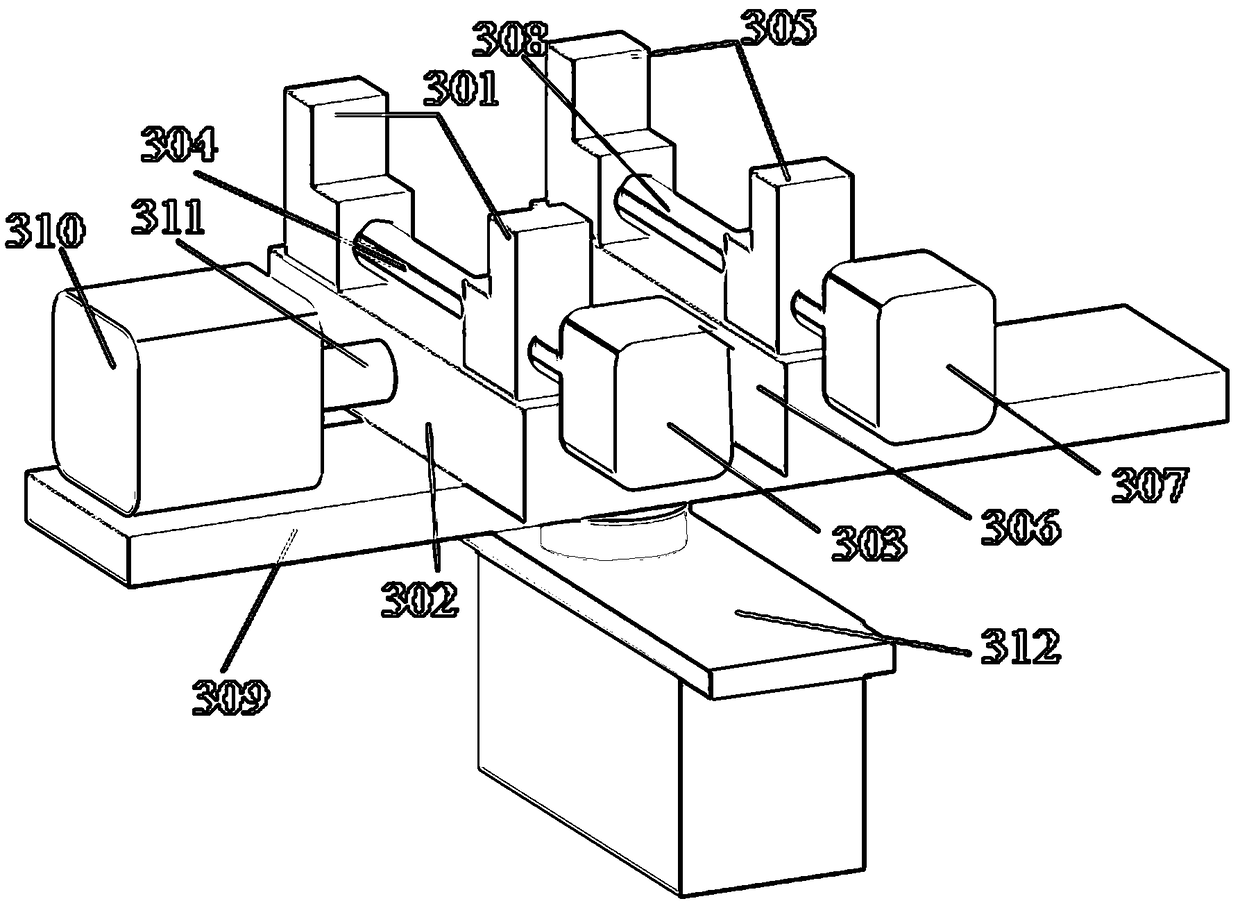

[0038] Such as figure 1 , 2 , shown in 3, a kind of X-ray polycrystalline diffractometer uses multi-sample automatic sample changing device, described sample changing device comprises sample plate 1, sample transfer mechanism 2, sample replacement mechanism 3, photoelectric sensor module 4, photoresistor sensor Module 5, control circuit module 6 and power supply module 7, the photoelectric sensor module 4, photoresistor sensor module 5 is connected to the control circuit module 6, the photoelectric sensor module 4 is set at the sample transfer mechanism 2 pairs of sample plate 1 conveying action For detection, the photoresistor sensor module 5 is set at the diffractometer to detect the brightness of the shutter light 9 of the diffractometer; the control circuit module 6 is connected to the sample transfer mechanism 2 and the sample replacement mechanism 3 controls it.

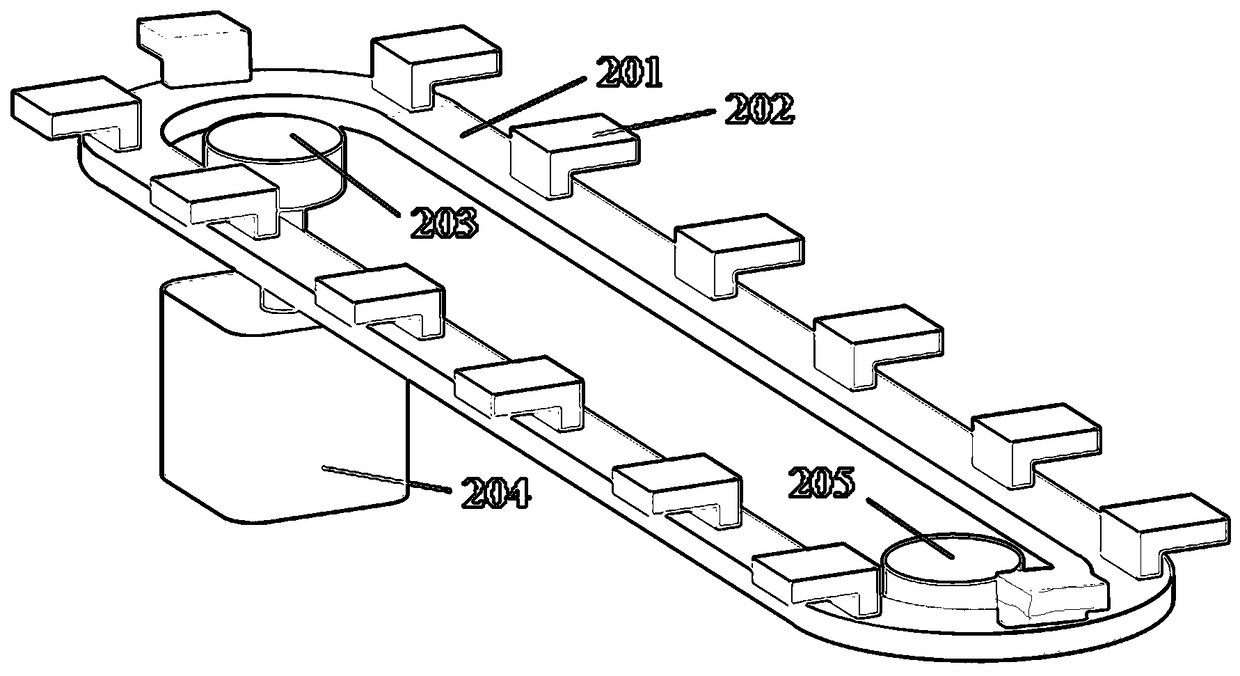

[0039] The sample transfer mechanism 2 includes a conveyor belt 201, an elastic pressing piece 202 and a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com