A cantilever bending test device for rock slab samples

A bending test, cantilever type technology, applied in the direction of measuring device, using stable bending force to test the strength of materials, instruments, etc., can solve the problems that are not suitable for the test of anti-dipping layered rock slope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

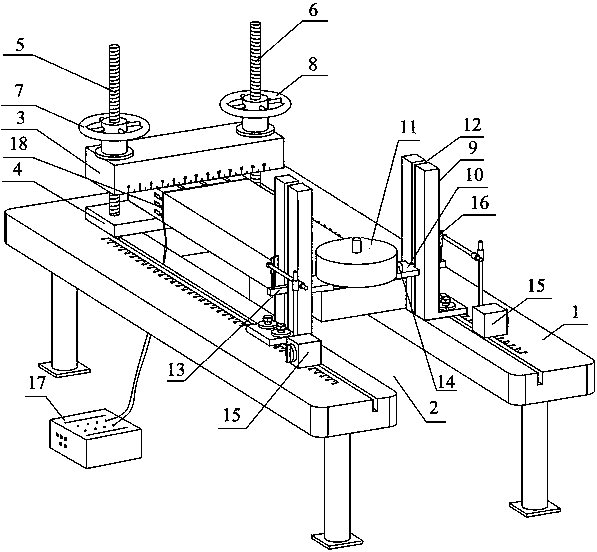

[0050] see figure 1 , a cantilever type bending test device for a rock slab sample, comprising a supporting platform 1 and a loading part, and also including a pressing part and a data acquisition part, the middle part of the supporting platform 1 is provided with a rectangular opening 2, and the pressing part includes The upper pressing block 3, the lower pressing block 4, the first screw rod 5, the second screw rod 6, the first runner 7 and the second runner 8, the lower pressing block 4 is fixed on the support platform 1, the first screw rod 5 and the second The screw rod 6 runs through the two ends of the upper pressing block 3 and the lower pressing block 4 respectively, the first runner 7 and the second runner 8 are respectively arranged at the two ends of the upper pressing block 3, and the first runner 7 and the first screw rod 5 pass through Threaded connection, the second runner 8 is threaded with the second screw rod 6; the load component includes a load bracket 9, ...

Embodiment 2

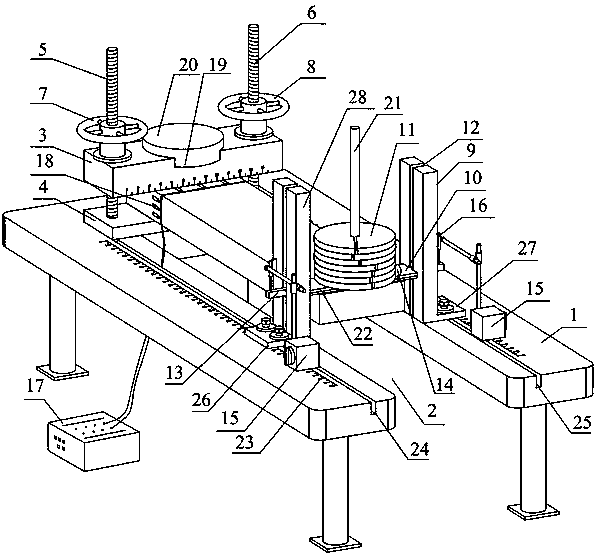

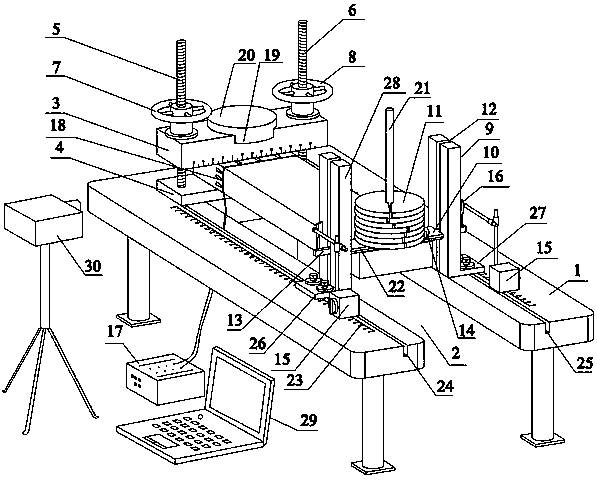

[0053] see figure 2 , a cantilever type bending test device for a rock slab sample, comprising a supporting platform 1 and a loading part, and also including a pressing part and a data acquisition part, the middle part of the supporting platform 1 is provided with a rectangular opening 2, and the pressing part includes The upper pressing block 3, the lower pressing block 4, the first screw rod 5, the second screw rod 6, the first runner 7 and the second runner 8, the lower pressing block 4 is fixed on the support platform 1, the first screw rod 5 and the second The screw rod 6 runs through the two ends of the upper pressing block 3 and the lower pressing block 4 respectively, the first runner 7 and the second runner 8 are respectively arranged at the two ends of the upper pressing block 3, and the first runner 7 and the first screw rod 5 pass through Threaded connection, the second runner 8 is threaded with the second screw rod 6; the load component includes a load bracket 9,...

Embodiment 3

[0059] see figure 2 , a cantilever type bending test device for a rock slab sample, comprising a supporting platform 1 and a loading part, and also including a pressing part and a data acquisition part, the middle part of the supporting platform 1 is provided with a rectangular opening 2, and the pressing part includes The upper pressing block 3, the lower pressing block 4, the first screw rod 5, the second screw rod 6, the first runner 7 and the second runner 8, the lower pressing block 4 is fixed on the support platform 1, the first screw rod 5 and the second The screw rod 6 runs through the two ends of the upper pressing block 3 and the lower pressing block 4 respectively, the first runner 7 and the second runner 8 are respectively arranged at the two ends of the upper pressing block 3, and the first runner 7 and the first screw rod 5 pass through Threaded connection, the second runner 8 is threaded with the second screw rod 6; the load component includes a load bracket 9,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com