Wave-front sensor, wave-front detection method and wave-front detection system based on microholographic array

A wavefront sensor and wavefront detection technology, applied in the field of adaptive optics, can solve the problems of increasing error and affecting the accuracy of wavefront reconstruction, etc., and achieve the effect of high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

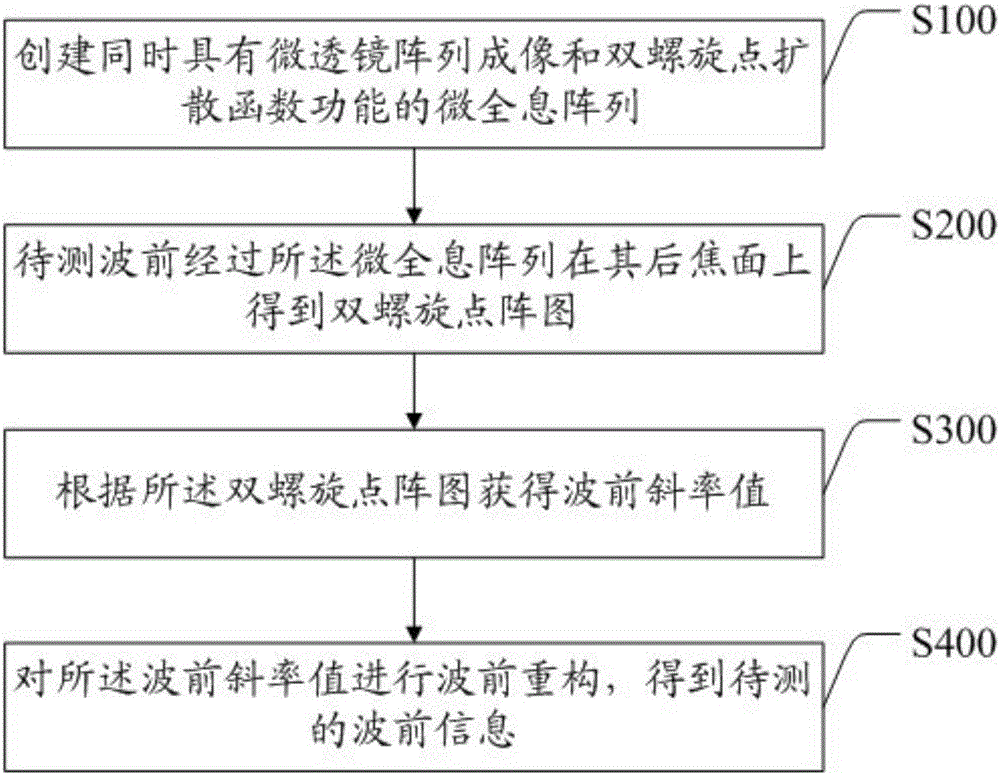

Method used

Image

Examples

Embodiment 1

[0101] The number of microlenses adopted is 5*5, the diameter of the microlens is 600 μm, and the focal length is 5mm. A spherical wave is generated by simulation, and the wavefront recovery is carried out by the wavefront detection method of the micro-holographic array of the present invention, such as Figure 9 as shown, Figure 9 (a) in (a) is the spherical wavefront to be analyzed; Figure 9 (b) in is the spherical wavefront phase distribution to be analyzed; Figure 9 (c) in is the recovered spherical wavefront; Figure 9 (d) in is the phase of the recovered spherical wave; Figure 9 (e) in is the wavefront difference between the spherical wave to be measured and the recovered spherical wave; Figure 9 (f) is the phase difference between the spherical wave to be measured and the recovered spherical wave, as can be seen from the figure, the spherical wavefront recovered by the wavefront detection method provided by the present invention is very close to the spherical wa...

Embodiment 2

[0103] The number of micro-lenses adopted is 5*5, the micro-lens diameter is 600 μ m, and the focal length is 5 mm, an arbitrary wave front (non-ideal plane wave) is simulated, and the wave front is recovered with the wave front detection method of the micro-holographic array of the present invention ,Such as Figure 10 as shown, Figure 10 (a) in is the wavefront to be analyzed; Figure 10 (b) in is the wavefront phase distribution to be analyzed; Figure 10 (c) in is the recovered wavefront; Figure 10 (d) in is the recovered phase; Figure 10 (e) is the wavefront difference between the wavefront to be measured and the restored wavefront; Figure 10 (f) in is the phase difference between the wavefront to be measured and the wavefront to be recovered, and at the same time, under the same simulation conditions, the wavefront to be measured is recovered by the traditional Shaker-Hartmann wavefront detection method, The root mean square error (RMSE) between the wavefront re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com