Air duct with total heat exchanging function

A heat exchange tube and full heat exchange technology, which is applied in the field of air ducts with full heat exchange function, can solve problems such as air mixing and affect the quality of fresh air, and achieve the effect of reducing ventilation resistance and ensuring the quality of fresh air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Such as figure 2 As shown, the thermally conductive spacer 3 is in the shape of a flat plate. The heat-conducting insulating layer 3 is arranged in the heat-exchange tube 1 along the diameter direction of the heat-exchange tube 1 , thereby dividing the heat-exchange tube 1 into a first heat-exchange channel 11 and a second heat-exchange channel 12 . The first manifold 21 and the second manifold 22 of the separation pipe 2 are plane-symmetric with respect to the flat heat-conducting insulating layer 3 . The cross-section of the heat-conducting insulating layer 3 is wavy, specifically, it may be in a saw-tooth shape, a wave shape, or a truncated cone shape, so as to increase heat exchange efficiency.

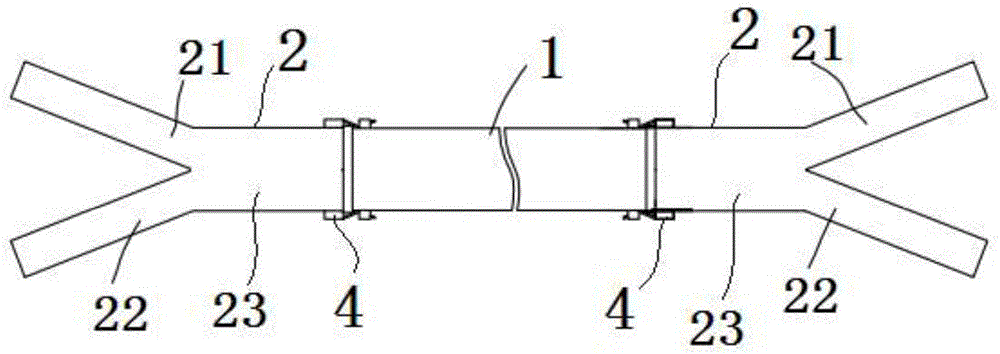

[0037] The heat exchange tube 1 and the two separating tubes 2 can be integrally formed. In addition, if figure 1 As shown, the heat exchange tube 1 can also be plugged with the two separation tubes 2 respectively. Specifically, the separation pipe 2 also includes a tr...

Embodiment 2

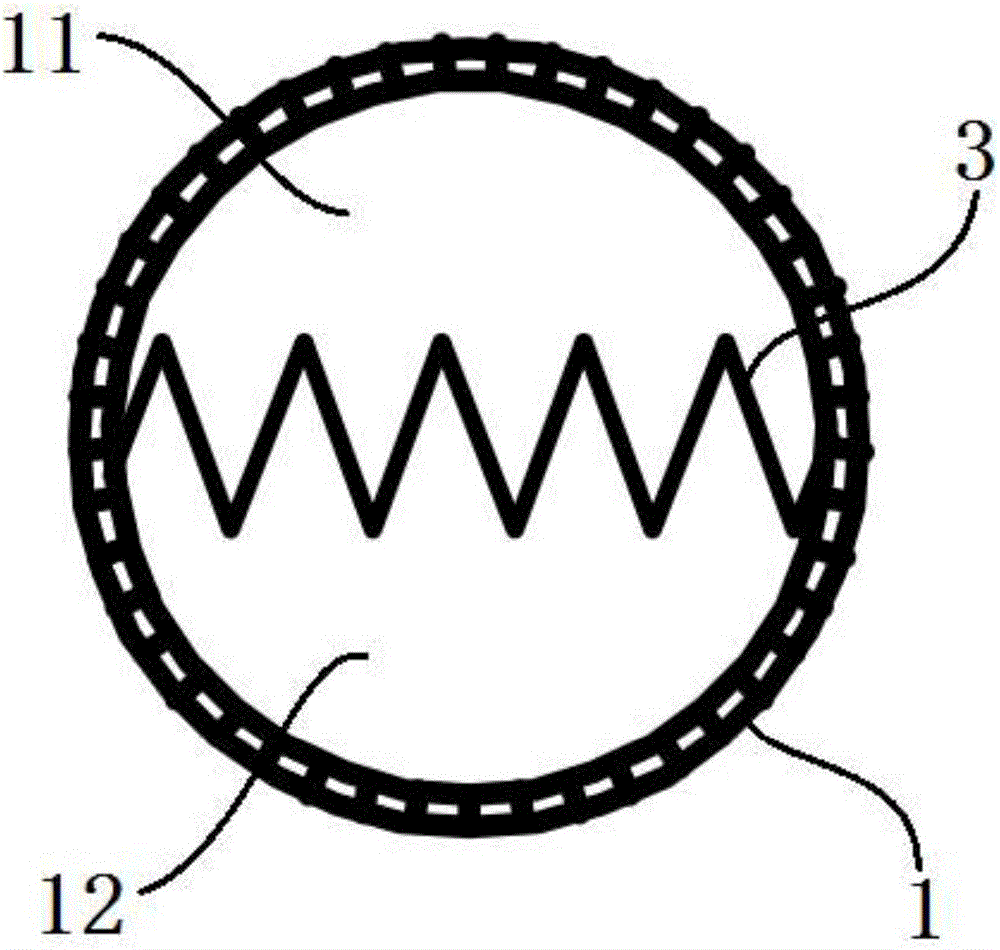

[0044] Such as Figure 5As shown, the thermally conductive spacer 3 is cylindrical. The cross-section of the heat-conducting interlayer 3 is circular, and may also be square or elliptical. The heat conduction interlayer 3 is sleeved in the heat exchange tube 1 , and the heat conduction interlayer 3 is coaxial with the heat exchange tube 1 . Several supporting ribs 101 are erected on the inner wall of the heat exchange tube 1 , and the supporting ribs 101 are used to support the heat-conducting insulating layer 3 . Each support rib 101 is distributed at equal intervals around the heat conduction spacer 3 around the tube axis of the heat exchange tube 1 , so that the position of the heat conduction spacer 3 is fixed. The inner cavity of the heat conducting insulating layer 3 is the first heat exchange channel 11 ; the annular channel between the heat conducting insulating layer 3 and the heat exchanging tube 1 forms the second heat exchanging channel 12 . The cross-section of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com