In-pipe energy supply equipment with turbine

A kind of equipment and leather bowl technology, applied in mechanical equipment, pipe components, pipes/pipe joints/pipe fittings, etc., can solve the problems of poor passability, large workload, limited battery power, etc., to meet complex operation requirements, sufficient power, Powerful access to the effect of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

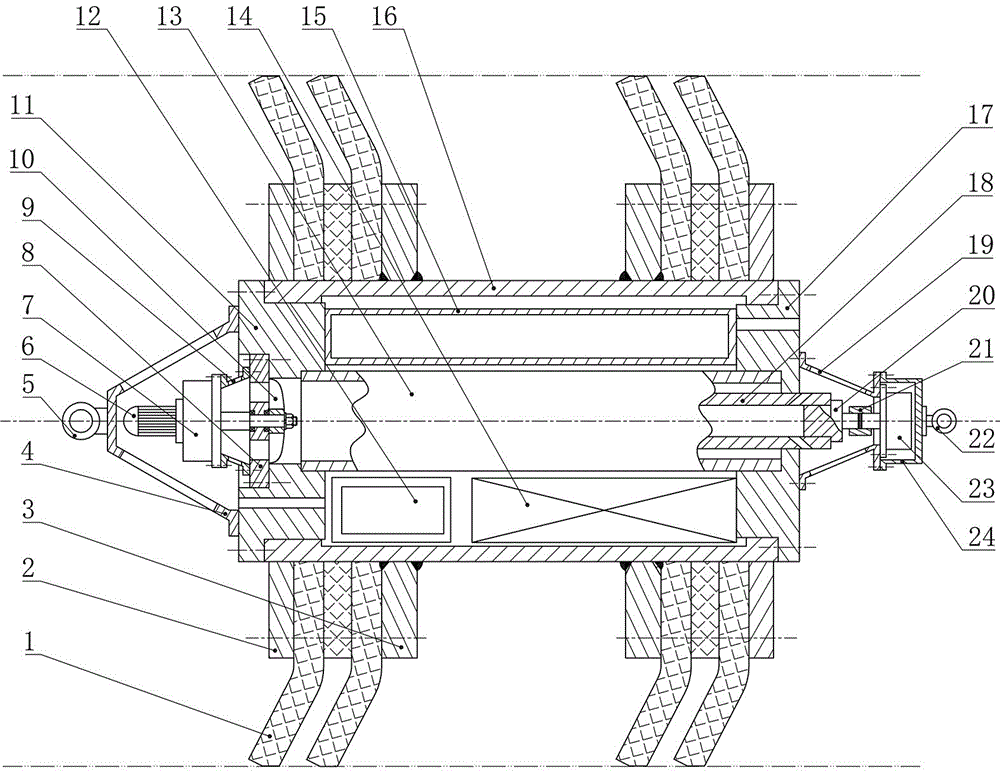

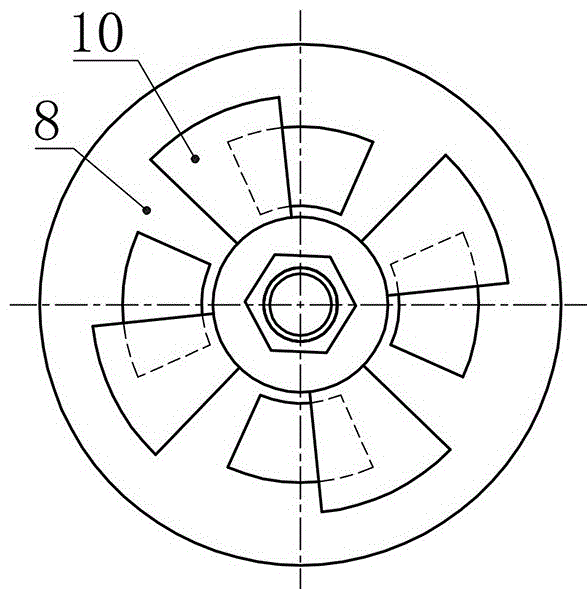

[0015] The present invention is not limited by the following implementation examples, and specific implementation manners can be determined according to the technical solutions of the present invention and actual conditions. Combine below figure 1 , figure 2 The present invention is described below. The positional relationship of up, down, left, right, etc. is based on the attached figure 1 determined by the layout direction.

[0016] The two ends of the cylinder body 16 are respectively equipped with a front end cover 17 and a rear end cover 11 and are fixed with bolts. Two fixing rings 3 are arranged in the middle of the cylinder body 16 and are connected with the cylinder body 16 by welding. The leather cup 1 is installed on the fixing rings 3. Described leather cup 1 is dish-shaped leather cup 1, and baffle plate 2 is arranged on the outer side of leather cup 1, and baffle plate 2 and fixing ring 3 are connected with bolt and leather cup 1 is fixed on the fixing ring 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com