Energy adjustment method and energy adjustment system thereof

A technology of energy adjustment and kinetic energy, applied to belts/chains/gears, mechanical equipment, transmissions, etc., can solve problems such as low efficiency, energy waste, and increased weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

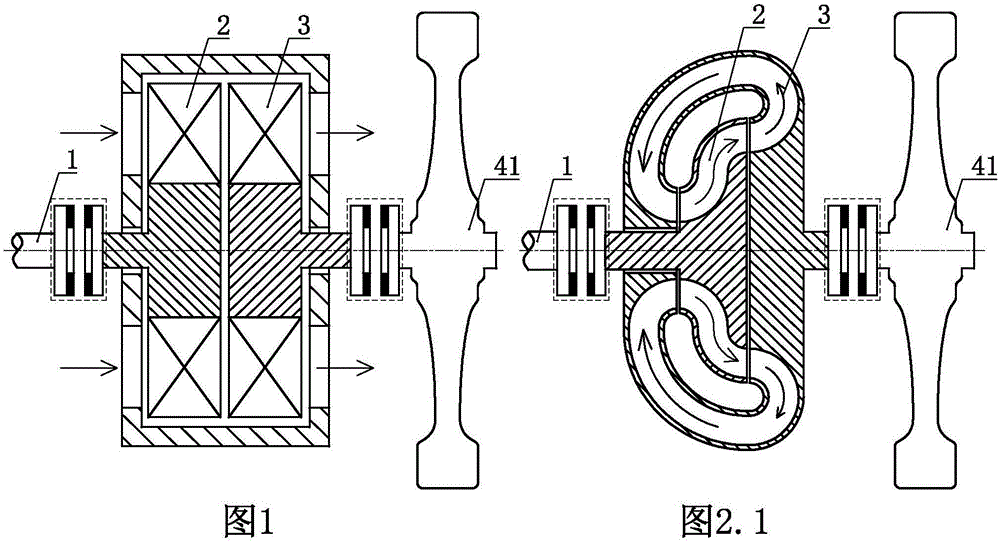

[0114] An energy adjustment method uses a mechanical transmission to drive an inertial body to store kinetic energy, and then uses the mechanical transmission to release the kinetic energy of the inertial body.

[0115] As a convertible implementation, the mechanical transmission described in Embodiment 1 of the present invention can be selectively selected as a mechanical continuously variable transmission or as a mechanical stepped transmission.

[0116] As an alternative embodiment, the mechanical transmission described in Embodiment 1 of the present invention can also be selectively replaced by a fluid transmission, a fluid torque converter or a fluid coupling.

Embodiment 2

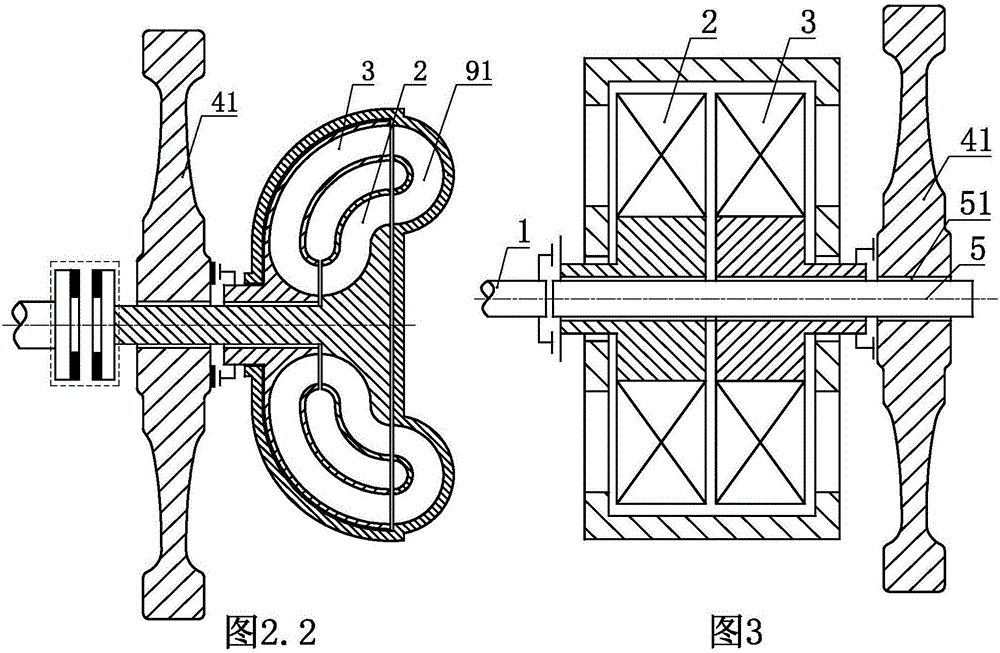

[0118] An energy adjustment method uses a fluid transmission to transmit the power of a rotating member to an inertia body to store kinetic energy, and then uses the fluid transmission to release the kinetic energy of the inertia body to the rotating member.

[0119] As a convertible implementation, the fluid transmission described in Embodiment 2 of the present invention can be selectively replaced by a mechanical transmission, a fluid torque converter or a fluid coupling.

Embodiment 3

[0121] An energy adjustment method uses a fluid torque converter to transmit the power of a rotating part to an inertia body to store kinetic energy, and then uses the same device to release the kinetic energy of the inertia body to other rotating parts.

[0122] As an alternative embodiment, the fluid torque converter in Embodiment 3 of the present invention can also be optionally replaced by a mechanical transmission, a fluid transmission or a fluid coupling.

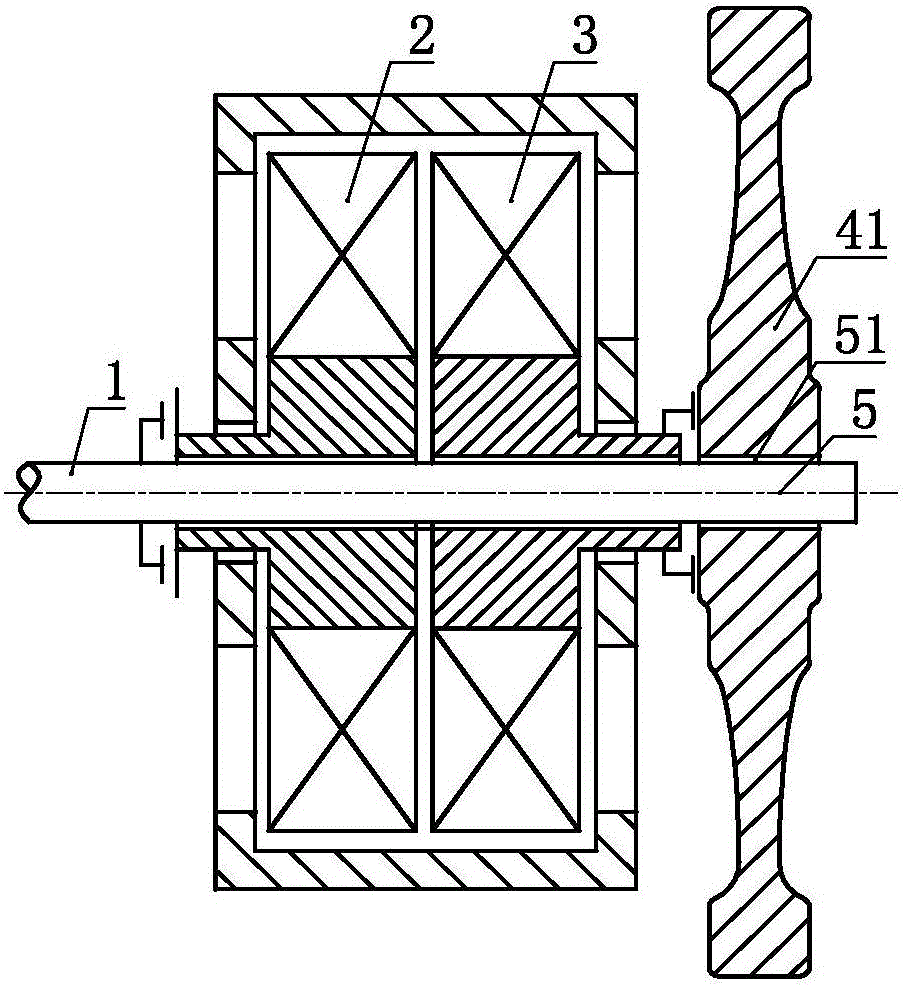

[0123] As a transformable embodiment, the embodiment 1 to embodiment 3 of the present invention and the embodiments that contain the mechanical transmission can be further selectively selected to make the mechanical transmission a mechanical gearbox. Or set it as a mechanical stepless gearbox.

[0124] As a changeable implementation mode, the embodiments that contain the fluid transmission in the embodiment 1 to the embodiment 3 of the present invention and their convertible implementations can further selectively cho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com