Engine with working condition capable of switching miller cycle logic

A Miller cycle and engine technology, which is applied to engine components, engine control, combustion engines, etc., can solve the problems of switching control difficulties and affecting engine power, and achieve the effects of good load response, increased power, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

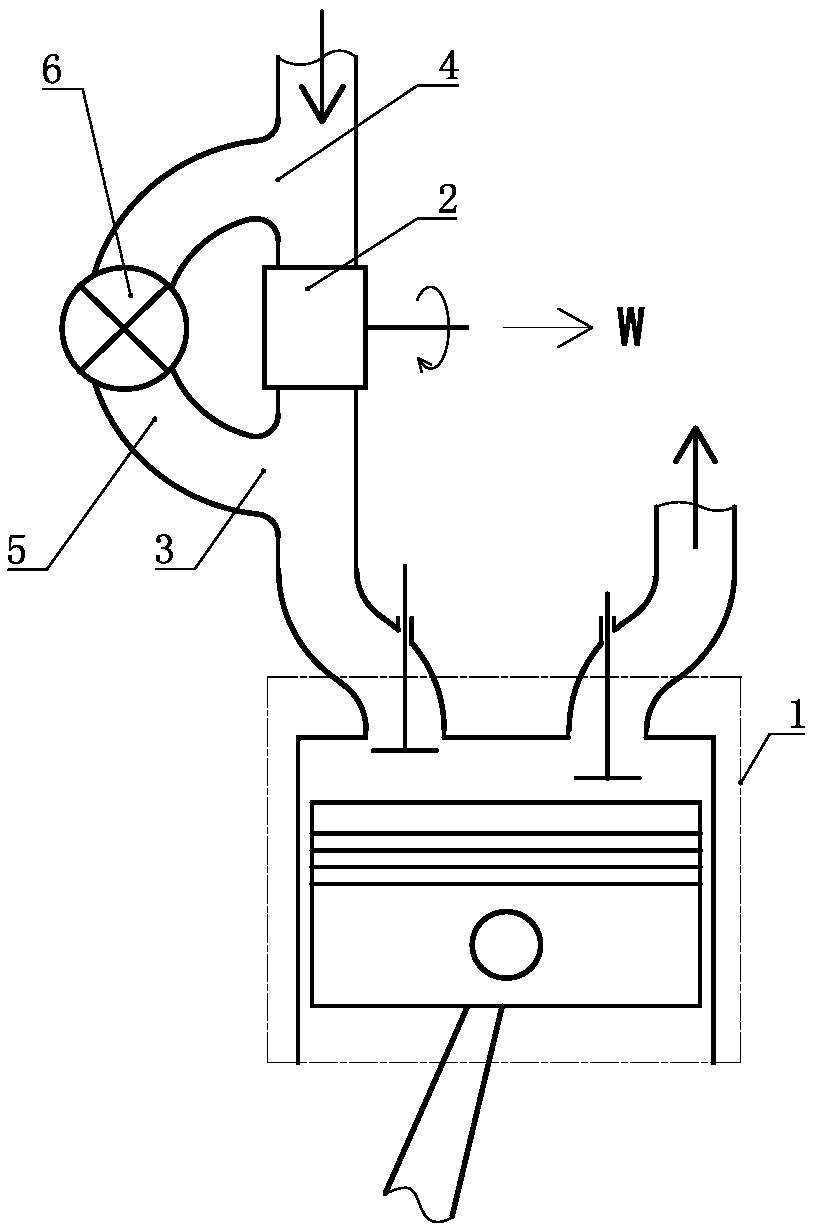

[0022] A mode switchable Miller cycle logic engine such as figure 1 As shown, a cylinder-piston mechanism 1 is included, and the cylinder-piston mechanism 1 is set as an adjustable compression ratio cylinder-piston mechanism. A seat opening bypass port 3 is provided on the communication channel between the working mechanism 2 and the air intake seat port, and an intake bypass port 4 is arranged on the working medium inlet passage of the working mechanism 2, and the seat port The port bypass port 3 communicates with the intake bypass port 4 via a bypass channel 5 , and a control valve 6 is arranged on the bypass channel 5 .

Embodiment 2

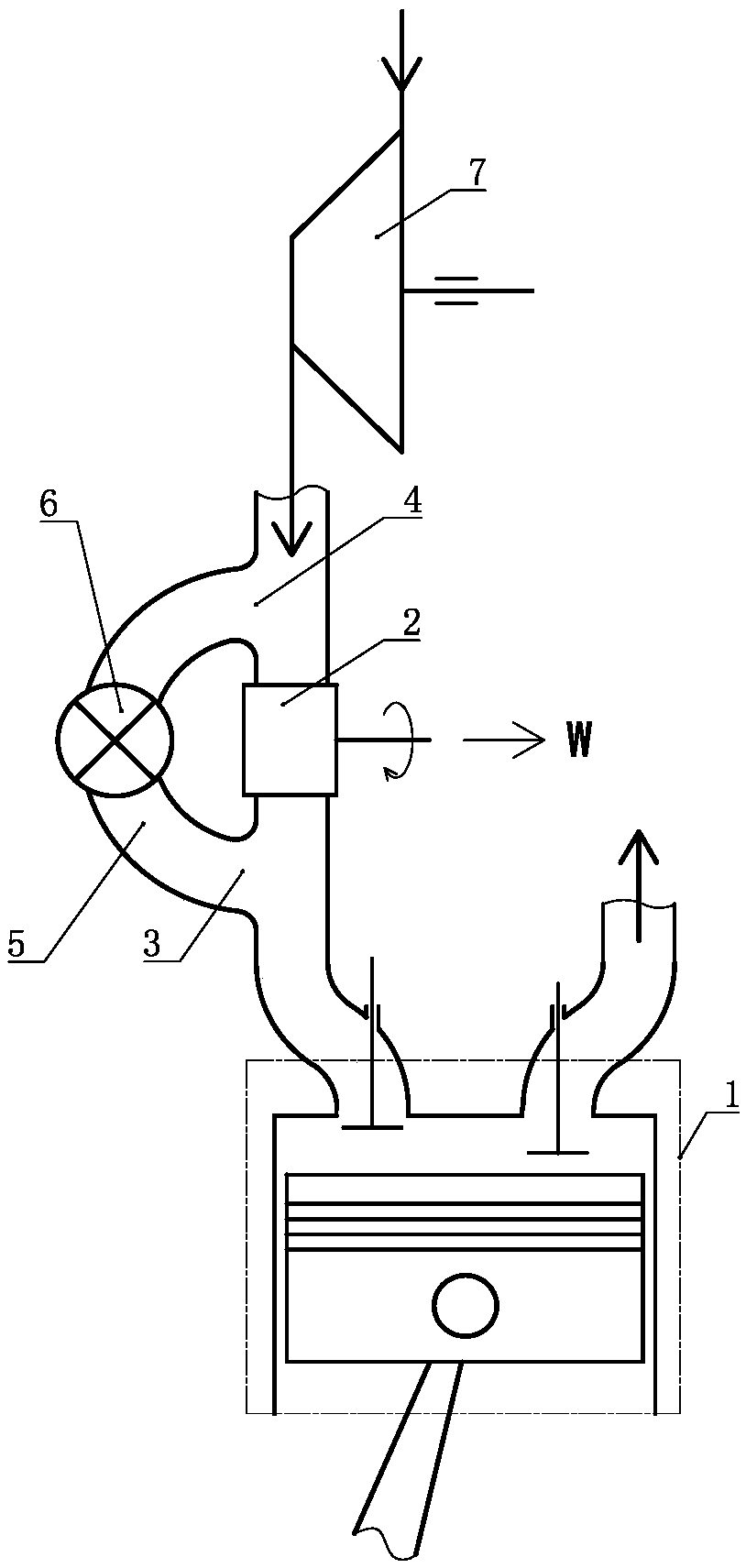

[0024] A mode switchable Miller cycle logic engine such as figure 2 As shown, a cylinder-piston mechanism 1 is included, and the cylinder-piston mechanism 1 is set as an adjustable compression ratio cylinder-piston mechanism. A seat opening bypass port 3 is provided on the communication channel between the working mechanism 2 and the air intake seat port, and an intake bypass port 4 is arranged on the working medium inlet passage of the working mechanism 2, and the seat port The bypass port 3 and the intake bypass port 4 are communicated with the bypass channel 5, and the control valve 6 is set on the bypass channel 5, and the working medium inlet of the working mechanism 2 and the working medium of the compressor 7 Quality export connectivity settings.

Embodiment 3

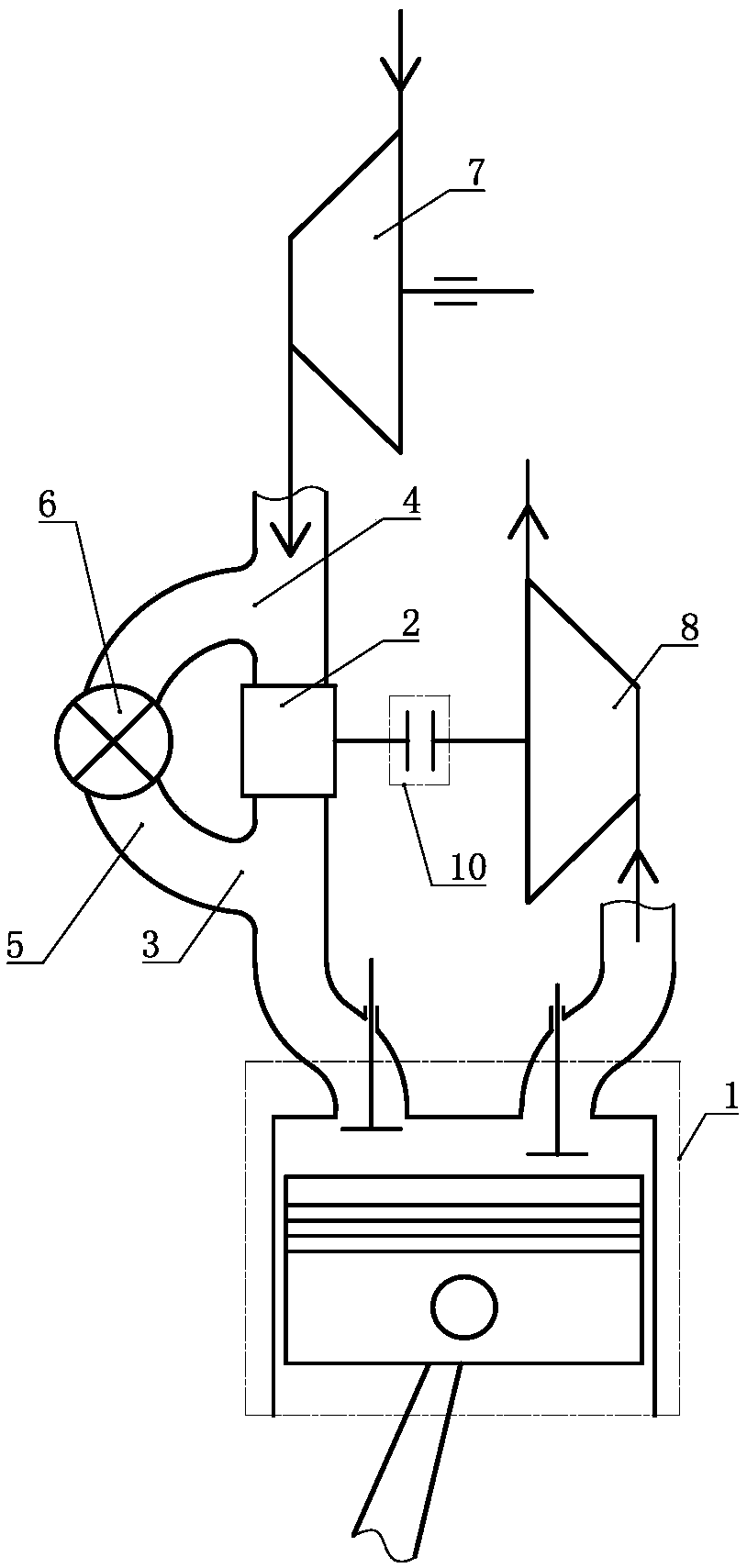

[0026] A mode switchable Miller cycle logic engine such as image 3 As shown, a cylinder-piston mechanism 1 is included, and the cylinder-piston mechanism 1 is set as an adjustable compression ratio cylinder-piston mechanism. A seat opening bypass port 3 is provided on the communication channel between the working mechanism 2 and the air intake seat port, and an intake bypass port 4 is arranged on the working medium inlet passage of the working mechanism 2, and the seat port The bypass port 3 and the intake bypass port 4 are communicated with the bypass channel 5, and the control valve 6 is set on the bypass channel 5, and the working medium inlet of the working mechanism 2 and the working medium of the compressor 7 The mass outlet is connected and set, the working mechanism 2 and the exhaust working mechanism 8 are set through the transmission of the clutch 10, the exhaust working mechanism 8 is arranged on the exhaust passage of the cylinder-piston mechanism 1, and the exhau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com