Double channel outer ring series connection type assembly angle contact ball bearing and assembly method thereof

A tandem, double-channel technology, used in ball bearings, bearing components, shafts and bearings, etc., can solve problems such as inconvenient bearing installation and adjustment, avoid axial preload adjustment time, simple installation, and simplified preload The effect of the repair process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

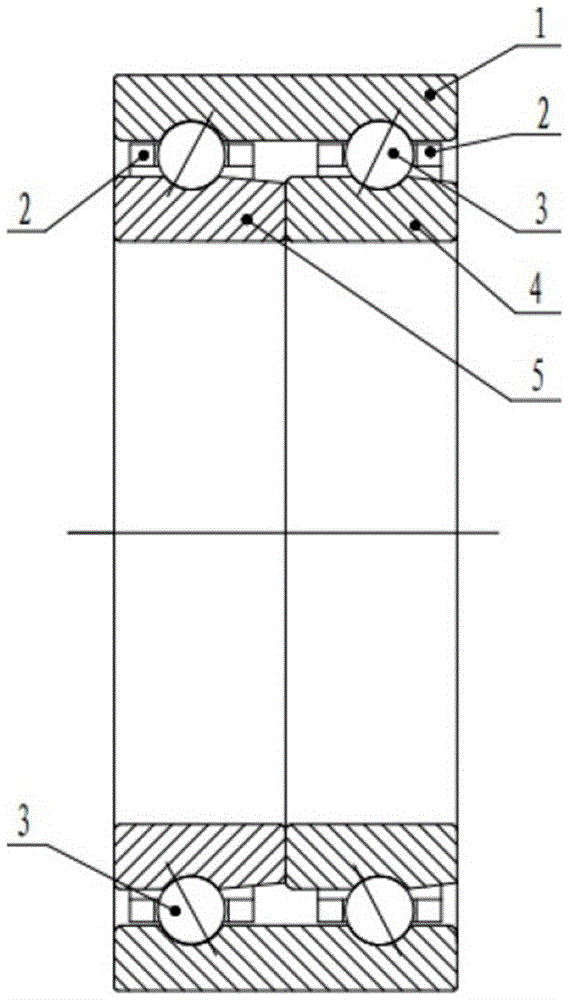

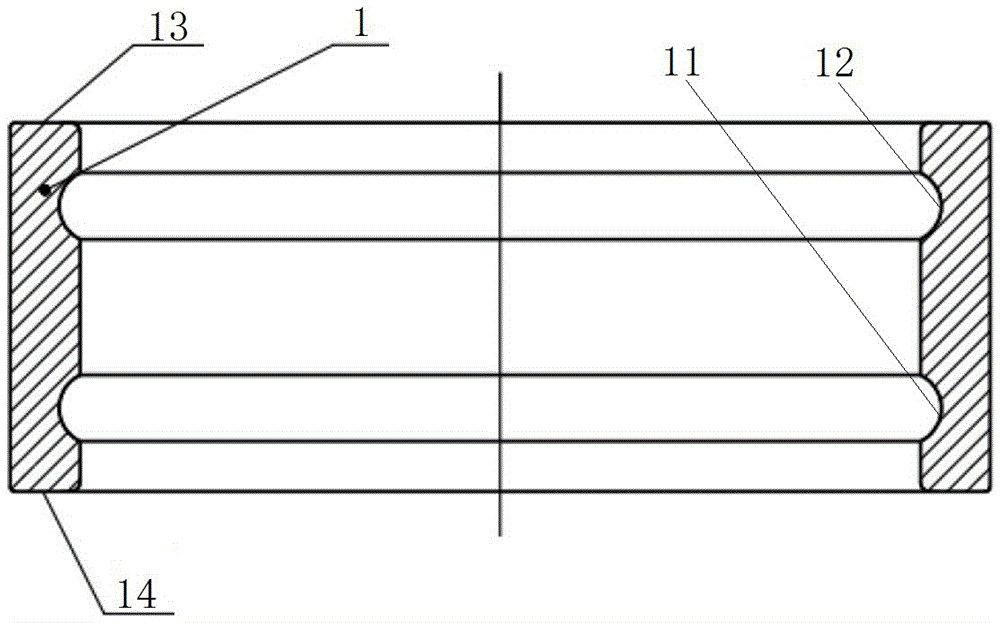

[0040] The assembly method of the double-channel outer ring tandem angular contact ball bearing of the present invention is the same as that of the double-channel outer ring tandem angular contact ball bearing in the embodiment of the double channel outer ring tandem angular contact ball bearing. , please refer to Figure 1 to Figure 5 , which will not be described in detail here.

Embodiment 2

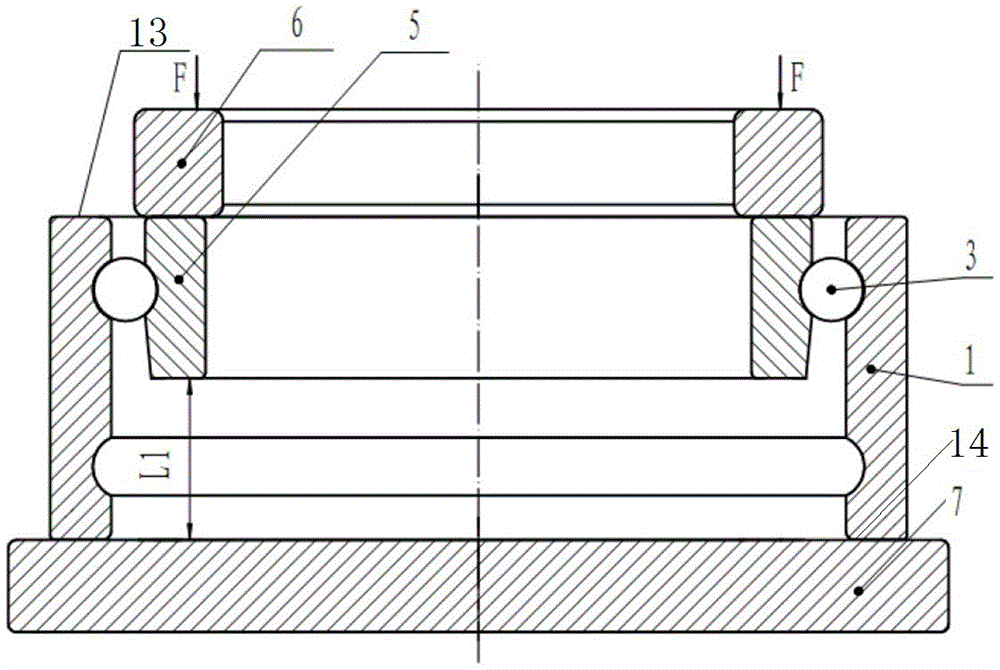

[0042] The only difference from Embodiment 1 of the double-groove outer ring tandem angular contact ball bearing assembly method is that in the second step, the first inner ring and the first inner groove of the outer ring are first fitted together, and The first inner ring applies a set load F that can move it toward the support plane and measures the distance L between the wide side end face of the first inner ring and the support plane at this time 2 ; The third step is to disassemble the first inner ring; the fourth step is to fit the second inner ring and the second inner channel of the outer ring to measure the second inner ring under the condition of axial load F Distance L between the narrow end of the inner ring and the support plane 1 ; In the eighth step, it is necessary to fit the first inner ring and the ground second inner ring into corresponding inner grooves of the outer ring.

[0043] In this embodiment, when performing the eighth step to fit the first inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com